Hi everyone,

I'm in the middle of this aquarium build, so I would like to share my experience so far.

I started out wanting to build a liquid rubber/plywood 8' x 2' x 2' aquarium, but I'm not really happy how the liquid rubber is going down. I found some HDPE panels at Menards for ~50$ a 8' by 4' sheet, so I'm going to line my aquarium with this after I use up 1 gallon of the liquid rubber and use the other gallon I bought for this project on the basement.

I'm a novice at aquariums, but I feel I'm a pretty good non-professional craftsman. I'm doing this more because I enjoying building things than trying save some money.

So, this is what I've done so far.

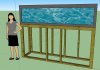

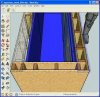

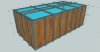

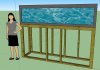

Went to http://www.garf.org/tank/buildtank.asp, and put in the dimensions I wanted for my aquarium (8'x2'x2). I picked these dimensions because this is the best use of 2 8'x4' sheets of plywood. I'm using 3/8" thick glass ($220). Went to sketch-up and designed my aquarium and stand. I'm building it higher than most aquariums and cleaning is going to be difficult, but I like that it is unique.

So, went to pick up the wood at home depot, and had them cut it for me.

Next, I pre-drilled, glued and screwed the plywood together to form the box.

After that, I cut the front windows out with my router.

I used normal epoxy to coat the outside of the aquarium to waterproof it from spills and what not. Built the stand, and cut the holes for my overflow, sump and drain.

I put Ames seam tape around the joints and where I cut holes for the drains.

Now I'm painting the interior with the liquid rubber.

Please let me know if you have any feedback and I will continue with the project.