So I have decided to go ahead with the build. I purchased my first wave of materials to get started and so far have only completed the base. I decided to stray from the original concept to save room on the height to keep some of the wall storage and to simplify the process. The reason why I went with concrete block on the bottom is because I wanted to make sure the wood was elevated away from the concrete floor because during heavy rain I sometime get a bit of water coming in from the garage door.

A quick disclaimer before I get into the pics, the garage has been used for my other hobbies over the years and has several stains from painting vehicles and is still highly crowded with tools. I had intentions of moving the car out of the middle before getting started but it was completely dead so I just covered her back up and went to work. I should still have room to do what is needed.

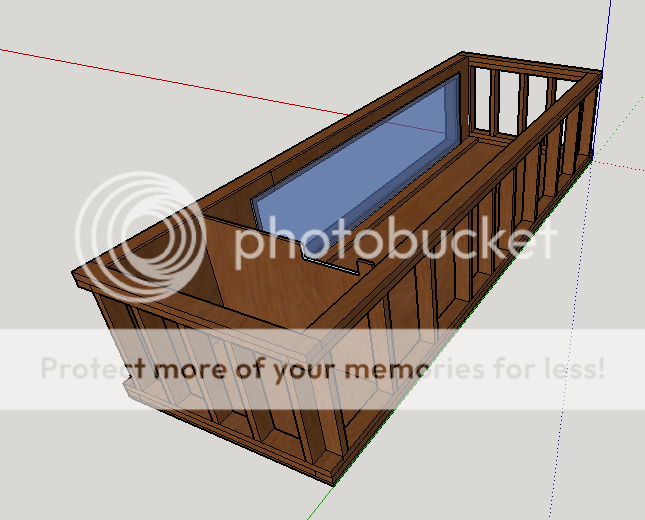

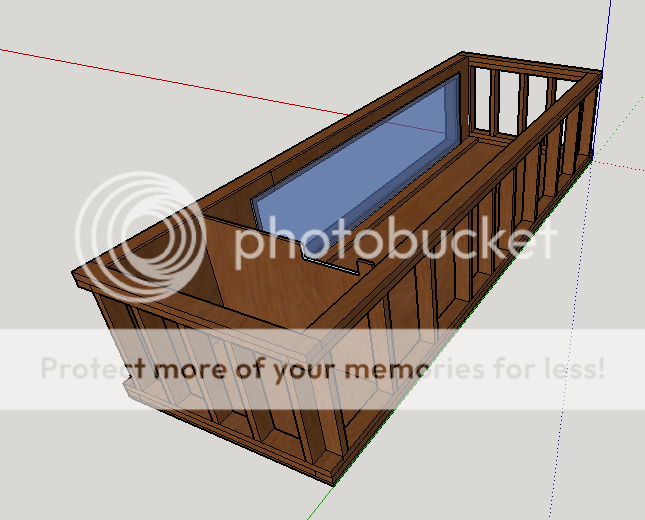

Here are a couple shots of the general tank plans (I may stray a bit from it as we go and interior/exterior will all be skinned and filled with insulation.

Then I used R13 to insulate the bottom held up by wire and nails (really not sure if this is the best way to do it but it worked with what I had laying around the garage.

And this is where I left it, there are two layers of plywood with the seem on opposite sides, hopefully this will help prevent issues in the future. The seems also rest on top of a 2x8 which is sitting directly on the concrete blocks, should be zero flex.

A quick disclaimer before I get into the pics, the garage has been used for my other hobbies over the years and has several stains from painting vehicles and is still highly crowded with tools. I had intentions of moving the car out of the middle before getting started but it was completely dead so I just covered her back up and went to work. I should still have room to do what is needed.

Here are a couple shots of the general tank plans (I may stray a bit from it as we go and interior/exterior will all be skinned and filled with insulation.

Then I used R13 to insulate the bottom held up by wire and nails (really not sure if this is the best way to do it but it worked with what I had laying around the garage.

And this is where I left it, there are two layers of plywood with the seem on opposite sides, hopefully this will help prevent issues in the future. The seems also rest on top of a 2x8 which is sitting directly on the concrete blocks, should be zero flex.