Acrylic Thickness help needed

- Thread starter suresh2989

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

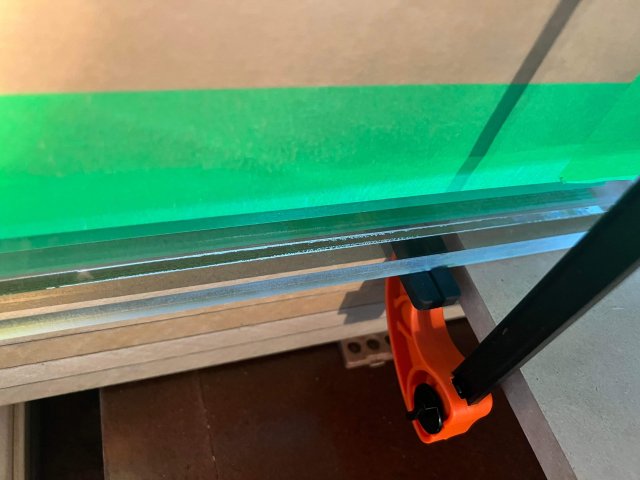

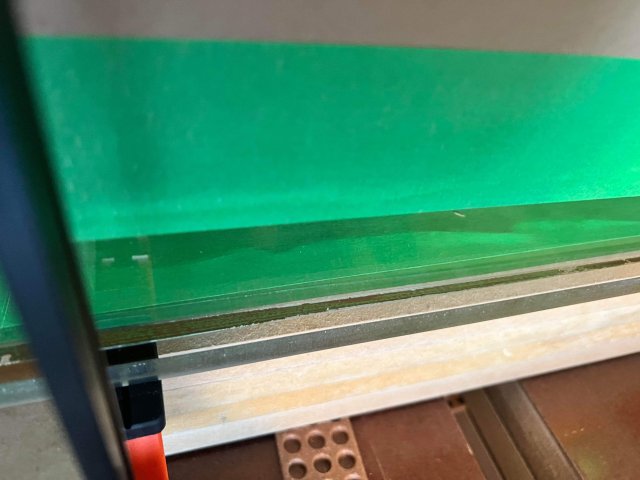

All Seams got an added strip making the surface area 1" vs the 1/2". Front seams that I botched a bit got inner and outer 45s inner is 1"x1" 45 and the outer is 2"x2" hiding the inside 45. Then I ran strips across the front bottom and top to make it look decent.Do you have closeup pics of the seams and your reinforcement work ? That is a very good idea btw and I’m curious to learn to use it for my future builds.

missed part of your question. i used a diablo 90 tooth blade for plastics on a table saw. turned out great but i still needed some edge prepping. from my understanding cnc cut uses an up-spiral cutting bit in a router. i would still prep the edges in that case. i routed all my corners after it was assembled and the spots i never prepped after has some bit marks after flame polishing.I completely agree, while I used single panel top with cutouts for my project I do think eurobracing should be enough, yours look very clean did you have prior experience building these ? Awesome job btw and did you saw your panels are saw cut ? Mine was CNCed so I didn’t have to do any edge prep.

U need a pro to build this aquarium sir , tell them u want the whole tank made from 1/2inch ,

Don't be like that; the man is building a basic box that contains water, not a time machine or a nuclear device. Aside from the considerable satisfaction that is derived from doing something like this for yourself, the simple fact is that a DIY tank, done carefully and with appropriate prior research, is at least as good from a functional standpoint as any commercially-produced unit. Cosmetically, it takes care and patience to make it perfect but that is also do-able.

OP, that's some nice work; congrats! I've built a lot of both glass and plywood tanks, but never got up the nerve to try acrylic. Good on you!

it starts to really get interesting when you pull up data sheets for products we use on glass and acrylic tanks.Don't be like that; the man is building a basic box that contains water, not a time machine or a nuclear device. Aside from the considerable satisfaction that is derived from doing something like this for yourself, the simple fact is that a DIY tank, done carefully and with appropriate prior research, is at least as good from a functional standpoint as any commercially-produced unit. Cosmetically, it takes care and patience to make it perfect but that is also do-able.

OP, that's some nice work; congrats! I've built a lot of both glass and plywood tanks, but never got up the nerve to try acrylic. Good on you!

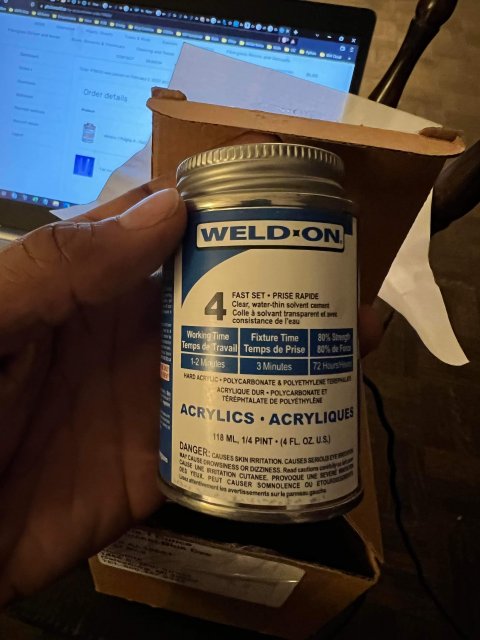

for example methylene chloride has a tensile strength of 2500psi and weldon 16 is 2200 psi. quality RTV and silicones are around 250-350.

so in theory this is to be taken with a grain of salt. at 22" tank height. 7" of properly bonded acrylic seam would be as strong as a full 22" seam of silicone or rtv.

thats best case scenario. no one is on here crying about there professionally made glass tank even though technically it holds a way lower safety factor then even a half assed acrylic tank. maybe my supplier on acrylic is just super affordable but other then the obvious lack of scratch resistance compared to glass. i dont see any benifit in using glass at all. other then the small tanks that can be bought new for 1$ a gallon anyways.

Before I retired I was often able to pick up large pieces of glass from renovations for free; built a lot of tanks that way, basically for the cost of silicone and my labour. That, combined with the fact that as a student I worked for an all-glass tank builder, made glass a no-brainer for me. Cutting the glass was always the biggest challenge for me; several tank plans underwent alterations in dimensions due to cutting accidents and miscues.

Never built or even owned an acrylic tank, not likely to start now. If I did, my first efforts would likely indeed be half-assed...whereas if I build anymore glass or plywood tanks going forward, I'm comfortable and confident that I can do a full-assed job of it...

Never built or even owned an acrylic tank, not likely to start now. If I did, my first efforts would likely indeed be half-assed...whereas if I build anymore glass or plywood tanks going forward, I'm comfortable and confident that I can do a full-assed job of it...

They look fine, added insurance is always better, but did the strips have to be black ?All Seams got an added strip making the surface area 1" vs the 1/2". Front seams that I botched a bit got inner and outer 45s inner is 1"x1" 45 and the outer is 2"x2" hiding the inside 45. Then I ran strips across the front bottom and top to make it look decent.

Don't be like that; the man is building a basic box that contains water, not a time machine or a nuclear device. Aside from the considerable satisfaction that is derived from doing something like this for yourself, the simple fact is that a DIY tank, done carefully and with appropriate prior research, is at least as good from a functional standpoint as any commercially-produced unit. Cosmetically, it takes care and patience to make it perfect but that is also do-able.

OP, that's some nice work; congrats! I've built a lot of both glass and plywood tanks, but never got up the nerve to try acrylic. Good on you!

Thanks so much for the kind words, I have never driven a screw in a wall before this project but I had time and space( my apartment was empty and to my self )so I am quite proud of the outcome and the things I learned along the way, after building the tank I had enough confidence to finish the stand myself too( metal part was done by professional fabricator) so yeah thanks again.

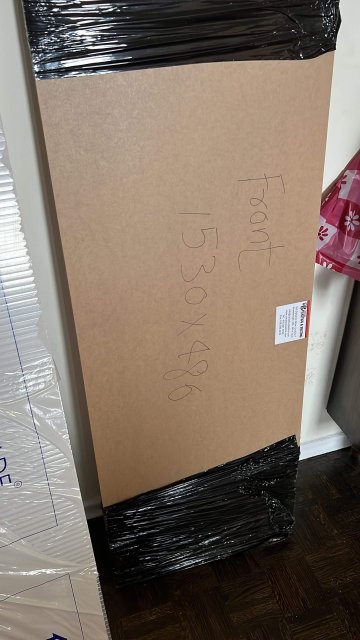

Here the more pictures from the project.Don't be like that; the man is building a basic box that contains water, not a time machine or a nuclear device. Aside from the considerable satisfaction that is derived from doing something like this for yourself, the simple fact is that a DIY tank, done carefully and with appropriate prior research, is at least as good from a functional standpoint as any commercially-produced unit. Cosmetically, it takes care and patience to make it perfect but that is also do-able.

OP, that's some nice work; congrats! I've built a lot of both glass and plywood tanks, but never got up the nerve to try acrylic. Good on you!