Hi all

I plan to build a large tank. I have considered different methods, and the "plywood-way" seems to be the easiest one. However as many others, i am not sure how to seal it. My interpretion of threads and articles is that people uses the epoxy/glasfiber or liquid rubber method. But both has drawbacks. Looking just at the finished result i like the epoxy/glasfiber method the most, but this seems to me also as the most complex way to do the construction. I have nok experience with epoxy or glasfiber. Epoxy is expensive, and bying the right one also is not easy in denmark. Another big drawback to me is the toxicity.

One drawback obviously with epoxy is that it is not very elastic. A was told that a board of plywood with length of 240cm can shrink/expand easily +/-1.5mm due to (room) humidity changes. This causes severe stress in all plywood junctions and the epoxy would easily crack (at least if not armed with fiber). Still by arming it with fiber i feel that the construction is not fully controlled. In other words i would also like the liquid rubber method which easily adapts to the geometry changes of the plywood box. Liquid rubber however are not riggid to handle a sharp rock punching against it. It also has this brownish color, and i guess the scraping of algeas will be tricky.

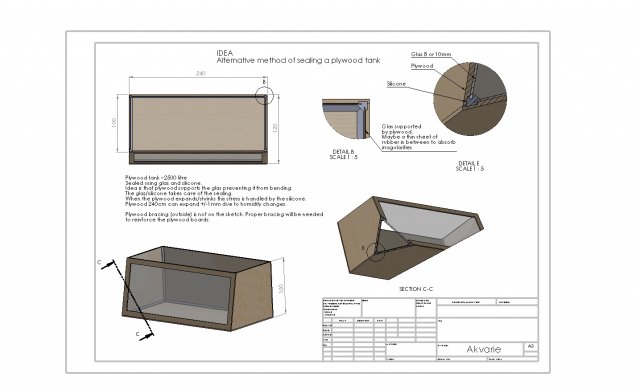

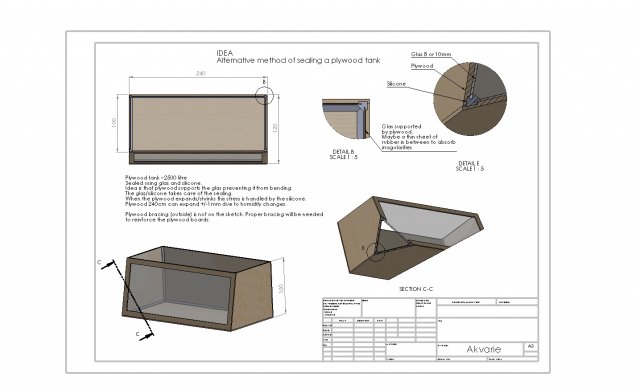

So is there any other methods. I have thougt of an alternative way (see attached jpg).

Using glass/silicone the traditional way, but using the plywood as a full support for the glass. This way much thinner glass can be used (this is what my logic tells me). In all corners where one piece of glass meets another an adequate volume of silicone is applied to seal and to absorb not only the movements due to water pressing against the whole structure, but also the movement caused by the plywood box shrinking or expanding.

If this will works one could have surfaces that are easily cleaned using an algea scraper. The glass can be painted any color on the backside (towards the plywood).

I have thought of similar methods using sheets of acrylic, but refused that idea because i don't know an elastic sealant that sticks to acrylic (that are also UV-resistant and healthy for living organism). Acrylic or other plastic material however would be nice because it tolerates irragularities (not as fragile and unpredictable as glass).

What do you think ?

Do you know threads/articles on similar thoughts ?

Am i missing something ?

Thanks in advance.

Best regards, Jon.

I plan to build a large tank. I have considered different methods, and the "plywood-way" seems to be the easiest one. However as many others, i am not sure how to seal it. My interpretion of threads and articles is that people uses the epoxy/glasfiber or liquid rubber method. But both has drawbacks. Looking just at the finished result i like the epoxy/glasfiber method the most, but this seems to me also as the most complex way to do the construction. I have nok experience with epoxy or glasfiber. Epoxy is expensive, and bying the right one also is not easy in denmark. Another big drawback to me is the toxicity.

One drawback obviously with epoxy is that it is not very elastic. A was told that a board of plywood with length of 240cm can shrink/expand easily +/-1.5mm due to (room) humidity changes. This causes severe stress in all plywood junctions and the epoxy would easily crack (at least if not armed with fiber). Still by arming it with fiber i feel that the construction is not fully controlled. In other words i would also like the liquid rubber method which easily adapts to the geometry changes of the plywood box. Liquid rubber however are not riggid to handle a sharp rock punching against it. It also has this brownish color, and i guess the scraping of algeas will be tricky.

So is there any other methods. I have thougt of an alternative way (see attached jpg).

Using glass/silicone the traditional way, but using the plywood as a full support for the glass. This way much thinner glass can be used (this is what my logic tells me). In all corners where one piece of glass meets another an adequate volume of silicone is applied to seal and to absorb not only the movements due to water pressing against the whole structure, but also the movement caused by the plywood box shrinking or expanding.

If this will works one could have surfaces that are easily cleaned using an algea scraper. The glass can be painted any color on the backside (towards the plywood).

I have thought of similar methods using sheets of acrylic, but refused that idea because i don't know an elastic sealant that sticks to acrylic (that are also UV-resistant and healthy for living organism). Acrylic or other plastic material however would be nice because it tolerates irragularities (not as fragile and unpredictable as glass).

What do you think ?

Do you know threads/articles on similar thoughts ?

Am i missing something ?

Thanks in advance.

Best regards, Jon.