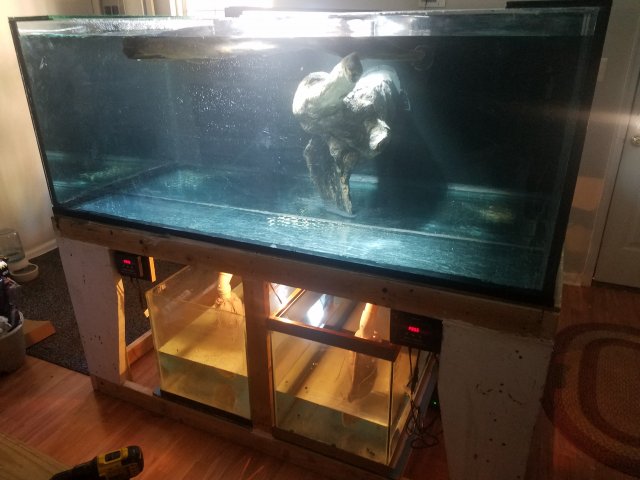

This couldve been exacerbating the leak issue before, as it appears that the four corner posts are indeed caving inwards once i get about 250-300 gallons on.

I will now have to drain and reconfigure the sumps and reinforce the stand i suppose, but at least i caught this issue before testing any further. If i work all day i could probably have it back into action by tomorrow.