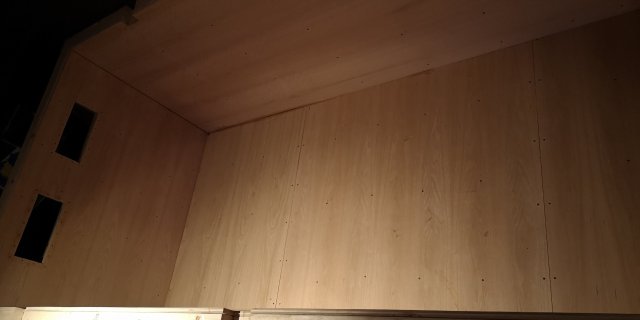

So some of this is already in another tgread i created but it was more about me asking what materials to use. Now that ive decided to go with a stacked 2x4 frame followed by oak plywood, acr epoxy fiberglass and sweet water paint top coat(s), here is the build so far. I obviously can't change what ive done but if anyone has suggestions moving forward i am happy to hear em. For the top bracing ill be putting in 3 2x4 braces lag bolted across the top that will then be eurobraced with 3/4 plywood. I also plan to use 3/4" glass for the front panel. Inside dimensions of the tank are 126"' by 50" by about 38" tall (29" water depth). Those overflows are actually pool skimmers that will be piped directly to the intake of my pumps. There is no sump but the output of my skimmer will be above the tank, so think of it like the skimmer is the tank and the tank is the sump if you want.