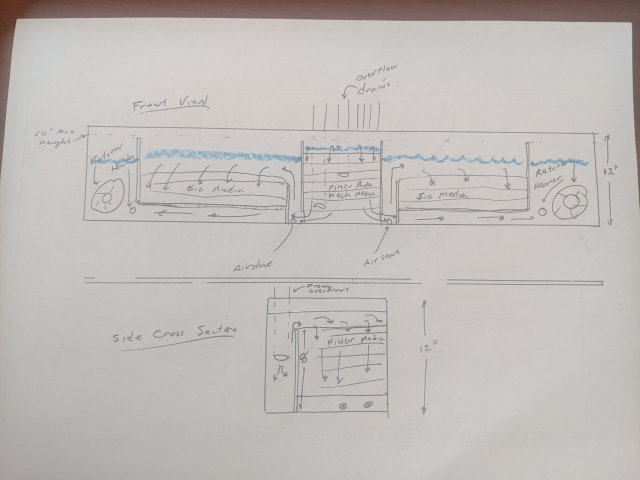

Building a sump out of 1/2" acrylic for my 300 gal aquarium. It is going in the stand built here:

300 gallon stand build

Sump dimensions will end up being 90" long x 16" wide x 13" tall (approx 80 gallon).

I got an old POS tank as well as a sheet of 1/2" acrylic off craigslist,that I used to cut the panels to size. Then I glued together with weld-on. Acrylic and that glue is some really nasty stuff. Cutting it smells terrible & the glue is really noxious stuff. My edges were not perfect so there were lots of bubbles in the seams. I am going to have to come back with some Weld-on 40 epoxy in the inside corners to make sure i have no leaks. Progress pics thus far:

300 gallon stand build

Sump dimensions will end up being 90" long x 16" wide x 13" tall (approx 80 gallon).

I got an old POS tank as well as a sheet of 1/2" acrylic off craigslist,that I used to cut the panels to size. Then I glued together with weld-on. Acrylic and that glue is some really nasty stuff. Cutting it smells terrible & the glue is really noxious stuff. My edges were not perfect so there were lots of bubbles in the seams. I am going to have to come back with some Weld-on 40 epoxy in the inside corners to make sure i have no leaks. Progress pics thus far:

Attachments

-

4.8 MB Views: 148

-

3.7 MB Views: 147