Okay all, so I’m trying to get everything ready for when I’m done polishing the 375 gallon tank. An issue that I’m currently running into are the bulk heads. In the back of the tank there are 3 returns and in the center of the tank are the overflows with 2 holes drilled in each box. My plan with the overflows is a 1” siphon in each overflow and a 3/4” drain in each one. The drains will be off set for water changes, one drain at 50% and the other at 75%. This way all I’ll have to do is open a ball valve to drain the tank.

Now my issue is that a standard 1” bulkhead head needs a 1 3/4” hole but when I removed the original owners bulkheads, (a total of 7 holes all drilled at 1 5/8”) the holes that are drilled are 1 5/8” so I’m having a pretty hard time finding bulkheads to fit.

I need the 3 back holes to be 3/4” thread x slip then for the overflows I need two 3/4” slip x slip and two 1” slip x slip.

I know the best route to remedy this situation is to get a 1 3/4” hole saw and make the hole bigger. This is an acrylic tank and I’m afraid that the hole saw might walk when starting it.

If anyone has an idea, or where to get slightly smaller outside diameter bulkheads please let me know.

planned on using the 3/4 life guards for the drains

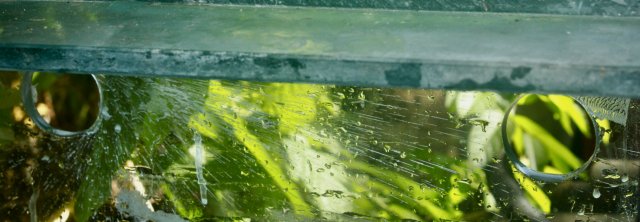

Here is also another issue, the holes in the overflow box’s are pretty close together

Now my issue is that a standard 1” bulkhead head needs a 1 3/4” hole but when I removed the original owners bulkheads, (a total of 7 holes all drilled at 1 5/8”) the holes that are drilled are 1 5/8” so I’m having a pretty hard time finding bulkheads to fit.

I need the 3 back holes to be 3/4” thread x slip then for the overflows I need two 3/4” slip x slip and two 1” slip x slip.

I know the best route to remedy this situation is to get a 1 3/4” hole saw and make the hole bigger. This is an acrylic tank and I’m afraid that the hole saw might walk when starting it.

If anyone has an idea, or where to get slightly smaller outside diameter bulkheads please let me know.

planned on using the 3/4 life guards for the drains

Here is also another issue, the holes in the overflow box’s are pretty close together