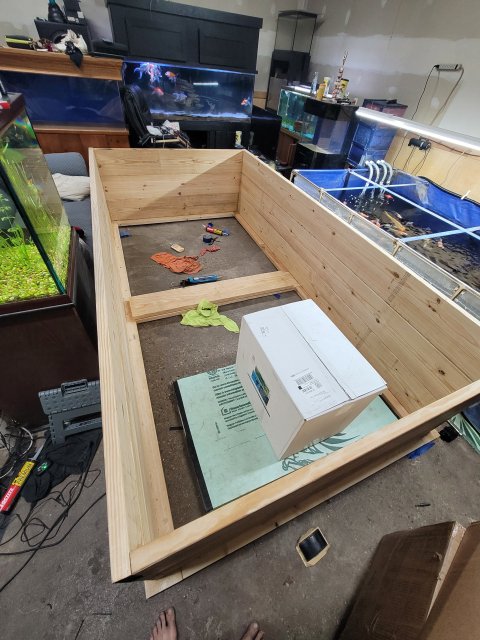

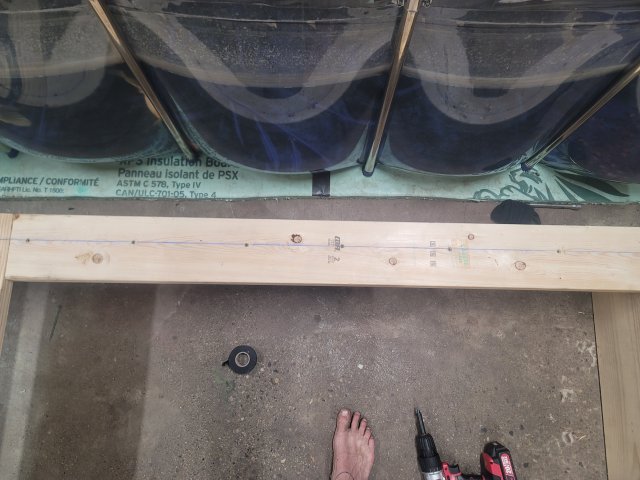

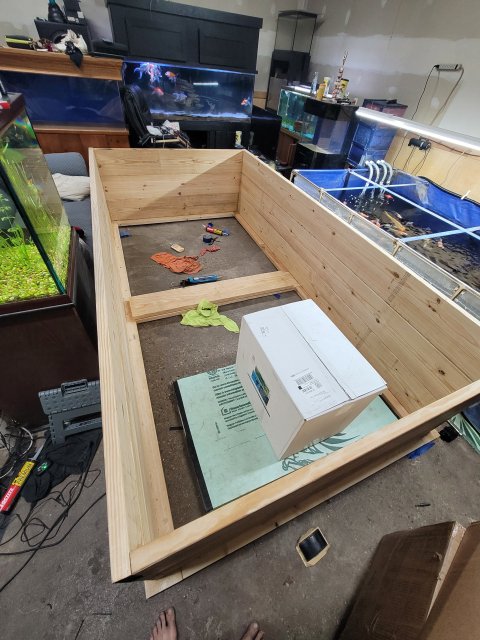

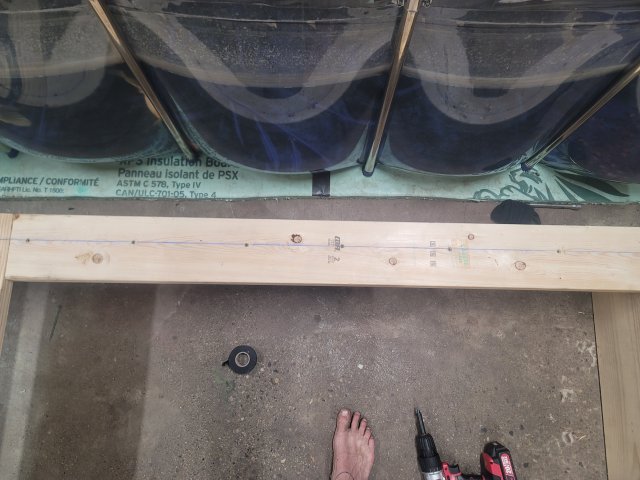

I'm honestly not sure how much I like the ostrich approach ("ignore it and hope for the best", lol) with regards to that floor, but I don't really know if that's just my OCD talking or if there really is a problem. You're right that the styro will be pressed down by the weight of the water to conform with the concrete, but what happens at the edges? In the first pic, the end furthest from the camera looks like it's an inch higher above the floor than the side on the right in the pic. I worry that the weight of the water will twist the wood downwards...or will it? If it doesn't twist, then it seems that the pond liner at that low point in the floor will be significantly stretched around the corner of the bottom bracing. And, worse yet, if it does twist...that doesn't sound good.

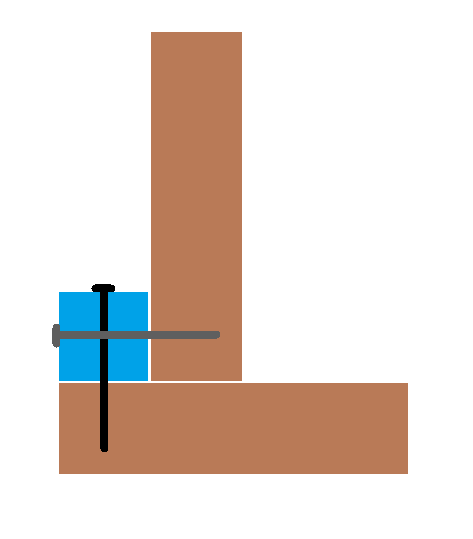

I know that in my plywood tank project that I just finished, I put a thick bead of cheap caulking along all the inside corners to support the liner so that it wouldn't stretch unduly. That was a PITA. In your project, it looks to me as though the weight of the water will be trying to pull the wood downwards, and it will be the liner itself that will take the brunt of it.

Not sure what is connecting the layers of vertical planks that comprise the sides. Is it mostly glue? Glue is super strong if applied correctly, but is even less forgiving when the structure twists than screws are.

I am wondering if it might be best to lay a sheet of styro on the floor that complete covers the entire footprint of the pond, and then put a second layer just to fill in the gaps between the bottom braces. I think that might compress more where the floor is highest, and less where it's lowest, and thus even up the entire wooden structure? Honestly, I'm just thinking out loud, I have no idea if that will work, but I really think this needs to be addressed.

I did, once upon a time, use a type of self-levelling concrete flooring to fix this exact problem; had to build a little corral around the entire "pad" area, then poured the concrete, allowed it to level, and set the tank on top of it. That worked well, the top of the pad was literally perfect, but the stuff wasn't cheap and wasn't particularly easy to mix and work with.

You know the old saying "measure twice, cut once"...this sounds to me like "think twice, or three times, build once". Hopefully someone else can chime in with ideas and suggestions.

M

M1A1

is already here and always has a pretty common-sense and realistic approach to construction ideas and problems. Maybe

Backfromthedead

Backfromthedead

has something to add?

Sorry if I am sounding negative, but my spider-sense is tingling...