Been keeping fish for decades but this is my first large tank with a sump and I could use some advice from the experts. Tank is a 220 Aqueon with double overflows plumbed with their Megaflow, Durso, type setup. The tank will be a planted Discus tank with a custom made background made to fit around the overflow boxes that have weirs cut at the bottom, middle and the top of the tank. The openings for these have a screen material behind these openings so the chance of any large particles getting into the sump is pretty low. Besides the sump I will also have an FX6 with mainly Bio Home Ultimate or other good Bio Media.

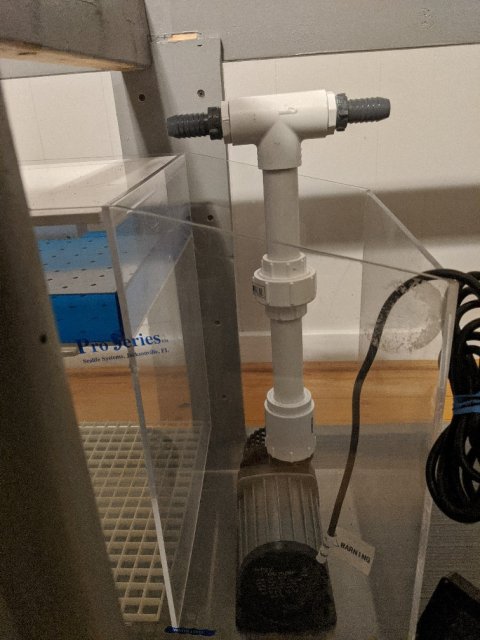

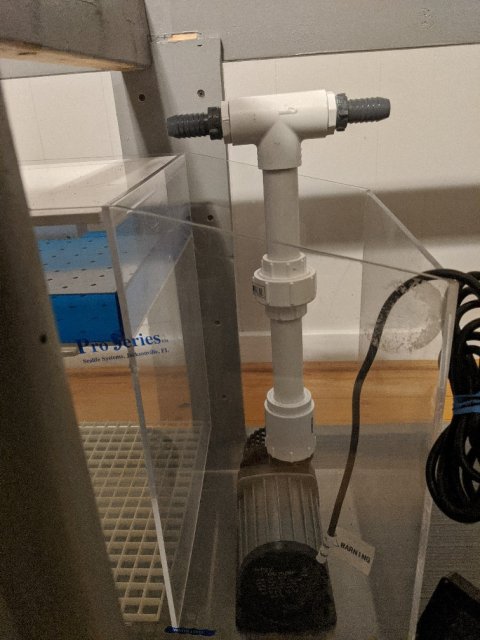

In my drawing I mention that I may run a double return pump but this won't be the case as only one will fit. It will either be a Jebao DCT 12000 or the DCT 8000. I would like advice on anything to do with this setup but my main issue is what to do with the intake section? Both drain lines will remain separated as they enter the sump. The ends of the drain lines are currently capped and the pvc has slots cut into them, I think for the water to enter the sump with less force creating noise? I suppose a filter sock could be used on them but from the research I have done most aren't crazy about socks. I suppose another option would to place some course round sponges around these that would catch larger particles or should I just leave them as they are?

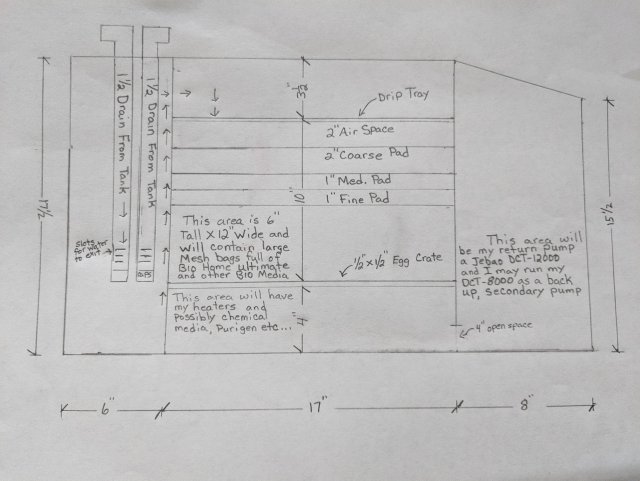

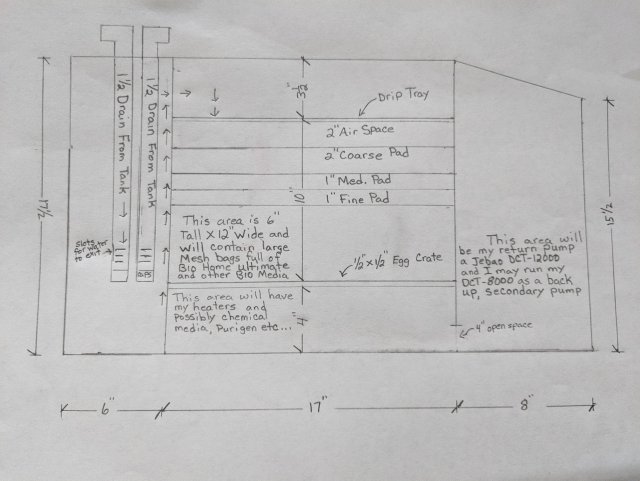

After the water enters the sump the water level rises to the top of the baffle where there is a large notch cutout and a flow plate is used to raise the height of where the water enters the middle section of the sump and mechanical filtration. The water passes into a drip tray that covers the entire top of this section. In the photo you can see how the tray is sagging in the middle, this will be corrected and made flat. My plan is to keep maybe an inch or two of air space between the bottom the drip tray and the first layer of foam pads that will fit the entire center section. I thought this air contact wouldn't be a bad thing as long as it's not crazy loud? The first sheet of foam with be a 2" thick course pad, then a 1" to 1 1/2" sheet of medium and finally a 1" to 1 1/2" sheet of fine. Under the fine pad will be large bags filled with Bio Media. All of these bags and filter pads will be sitting on a section of egg crate that is off the bottom of the sump about 4".

In the area under the egg crate will be where I place my heaters and if I ever needed to add some chemical filtration this will be where it would go. The baffle between the center section and the area on the far right where the return pump will be is up about 4" from the bottom of the sump. Is there a reason to place a large foam block in this area? I have seen many sumps using something similar to possibly catch any particles before the pump can inhale them. However as tight as the sheets of foam fit this center section I think it is darn near impossible for anything of any size to make it through the sump this far. The return line will have a True Union Spears Check Valve installed that isn't in the photos. The 1" return line will then T off and reduce to 3/4 where it will enter hose and go to the returns in each overflow. All drain and return lines will have valves just under the bulk heads to shut flow off when needed.

Now for my questions.

1) What should I do with the drain lines when they enter the sump, sponges, socks, leave alone or.............?

2) Should I place all the Bio Media in the FX6 and use the center section of the sump entirely filled with layers sponge sheets?

3) I spent a fortune on the background so I can hide everything possible from view. Would it be possible to have the intake and the return from the FX6 placed in one of the overflow boxes, or have the intake in one and the return in the other?

4) Any addition advice or warnings is also welcomed.

Below is a sketch I did of how I have the sump designed in my head as well as photos of the actual sump. Yes, I have read the forum threads and everything I could online for months, that is how I have gotten to this point already, lol!!!! Just need some advice before putting this plan to work. Thank you ahead of time for your advice and time. God Bless

NCH

In my drawing I mention that I may run a double return pump but this won't be the case as only one will fit. It will either be a Jebao DCT 12000 or the DCT 8000. I would like advice on anything to do with this setup but my main issue is what to do with the intake section? Both drain lines will remain separated as they enter the sump. The ends of the drain lines are currently capped and the pvc has slots cut into them, I think for the water to enter the sump with less force creating noise? I suppose a filter sock could be used on them but from the research I have done most aren't crazy about socks. I suppose another option would to place some course round sponges around these that would catch larger particles or should I just leave them as they are?

After the water enters the sump the water level rises to the top of the baffle where there is a large notch cutout and a flow plate is used to raise the height of where the water enters the middle section of the sump and mechanical filtration. The water passes into a drip tray that covers the entire top of this section. In the photo you can see how the tray is sagging in the middle, this will be corrected and made flat. My plan is to keep maybe an inch or two of air space between the bottom the drip tray and the first layer of foam pads that will fit the entire center section. I thought this air contact wouldn't be a bad thing as long as it's not crazy loud? The first sheet of foam with be a 2" thick course pad, then a 1" to 1 1/2" sheet of medium and finally a 1" to 1 1/2" sheet of fine. Under the fine pad will be large bags filled with Bio Media. All of these bags and filter pads will be sitting on a section of egg crate that is off the bottom of the sump about 4".

In the area under the egg crate will be where I place my heaters and if I ever needed to add some chemical filtration this will be where it would go. The baffle between the center section and the area on the far right where the return pump will be is up about 4" from the bottom of the sump. Is there a reason to place a large foam block in this area? I have seen many sumps using something similar to possibly catch any particles before the pump can inhale them. However as tight as the sheets of foam fit this center section I think it is darn near impossible for anything of any size to make it through the sump this far. The return line will have a True Union Spears Check Valve installed that isn't in the photos. The 1" return line will then T off and reduce to 3/4 where it will enter hose and go to the returns in each overflow. All drain and return lines will have valves just under the bulk heads to shut flow off when needed.

Now for my questions.

1) What should I do with the drain lines when they enter the sump, sponges, socks, leave alone or.............?

2) Should I place all the Bio Media in the FX6 and use the center section of the sump entirely filled with layers sponge sheets?

3) I spent a fortune on the background so I can hide everything possible from view. Would it be possible to have the intake and the return from the FX6 placed in one of the overflow boxes, or have the intake in one and the return in the other?

4) Any addition advice or warnings is also welcomed.

Below is a sketch I did of how I have the sump designed in my head as well as photos of the actual sump. Yes, I have read the forum threads and everything I could online for months, that is how I have gotten to this point already, lol!!!! Just need some advice before putting this plan to work. Thank you ahead of time for your advice and time. God Bless

NCH

Last edited: