Hey Y'all,

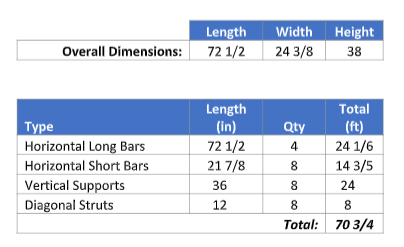

I'm building a new stand for the 185 gallon, and looking for feedback. I have a friend that offered to do the welding (he does a lot of auto body work and has a well equipped shop). His recommendation was to go with 1.25" steel tubing at 1/8" wall size. To me, this seems WAY stronger than some of the wood stands you get with tanks, but I'm curious if you all have any thoughts. With a 180g tank including water, rocks, sand, etc. I'm anticipating this needing to hold 2000 lbs. I'm not sure if it's needed or not, but I also included 8 diagonal struts to prevent shearing.

I plan to get this powder coated, then put a sheet of plywood on the top and bottom to prevent the tank from sitting directly on the metal. I also plan to wrap the stand in a more decorative wood. (My wife likes barn wood).

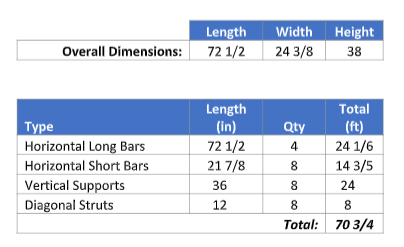

Definitely open to feedback if you have it. I'll share some pictures once we start the project. Also, apologies on the design -- my Sketchup skills are super rudimentary

Front View of the Stand

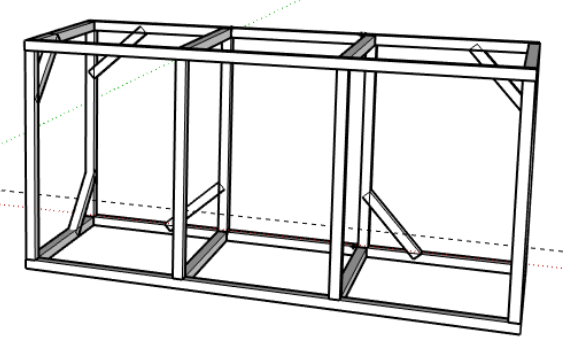

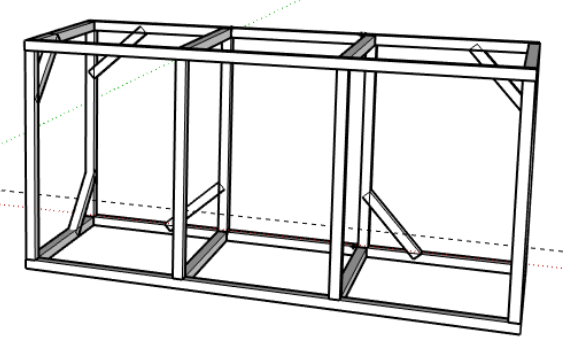

Back View of the Stand

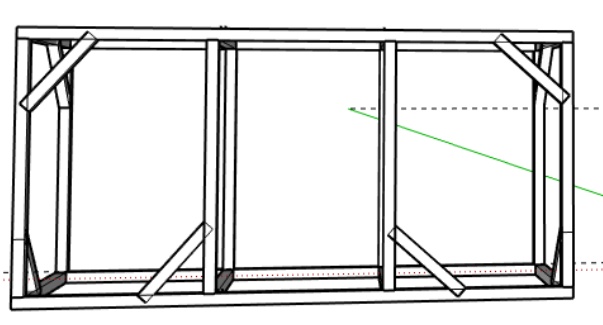

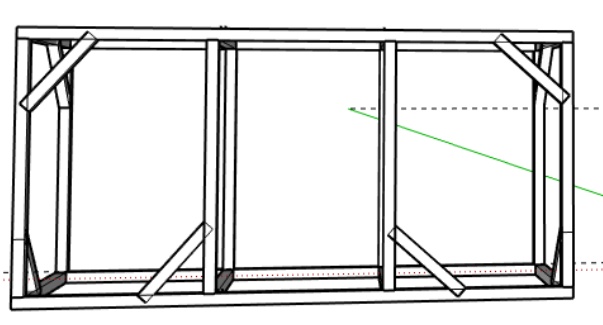

Side View (To show Diagonal Struts)

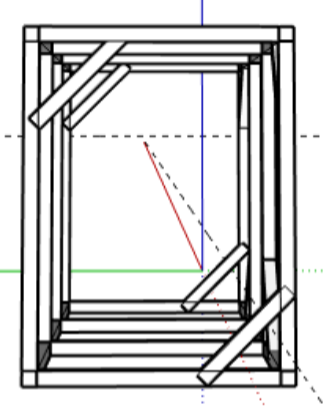

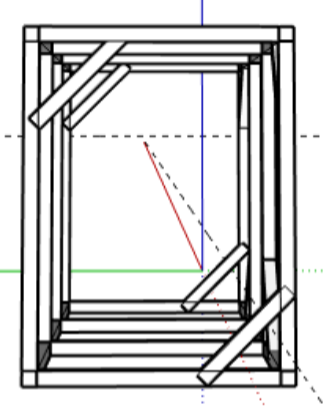

Stand Dimensions

I'm building a new stand for the 185 gallon, and looking for feedback. I have a friend that offered to do the welding (he does a lot of auto body work and has a well equipped shop). His recommendation was to go with 1.25" steel tubing at 1/8" wall size. To me, this seems WAY stronger than some of the wood stands you get with tanks, but I'm curious if you all have any thoughts. With a 180g tank including water, rocks, sand, etc. I'm anticipating this needing to hold 2000 lbs. I'm not sure if it's needed or not, but I also included 8 diagonal struts to prevent shearing.

I plan to get this powder coated, then put a sheet of plywood on the top and bottom to prevent the tank from sitting directly on the metal. I also plan to wrap the stand in a more decorative wood. (My wife likes barn wood).

Definitely open to feedback if you have it. I'll share some pictures once we start the project. Also, apologies on the design -- my Sketchup skills are super rudimentary

Front View of the Stand

Back View of the Stand

Side View (To show Diagonal Struts)

Stand Dimensions