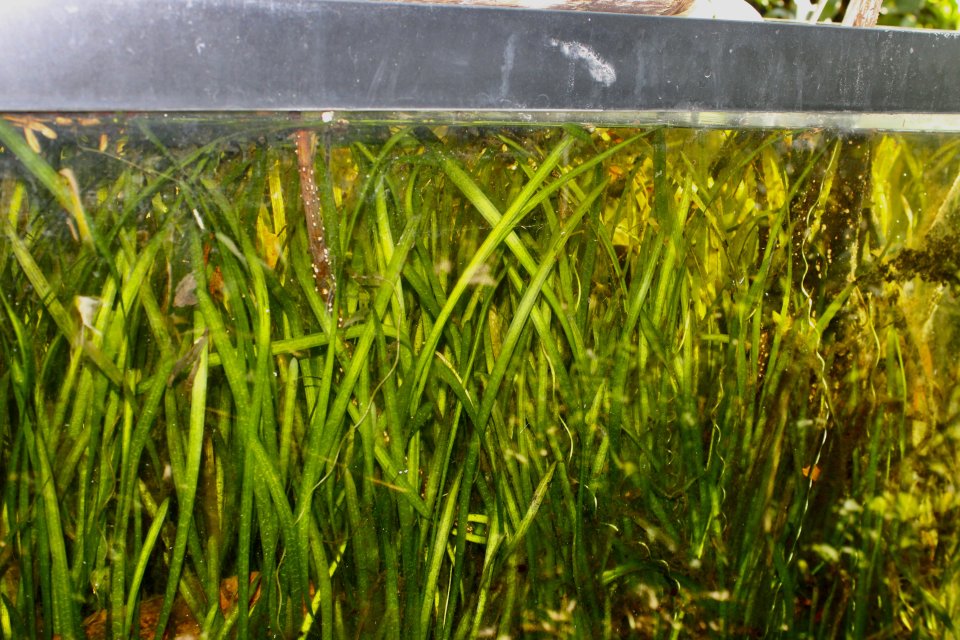

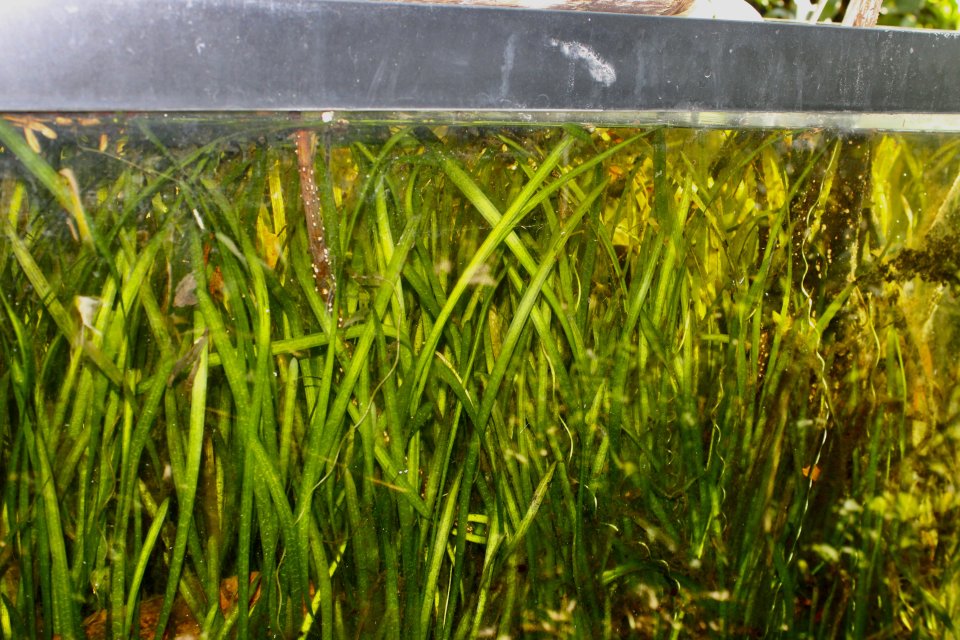

Because my sump is a 125 (6 ft) gal tank, it is set up similar to any planted tank (almost full to the rim with water), 80% is for plants, mostly aquatic Vallisneria, (and some water lilies to provide shade), tne plants are rooted in sand, with some floaters on the surface such as Salvinia.

And I agree thth Swiss tropicals accessment, with their foam panels acting as a wall, any need for extra bio-media seems a bit superflous.

On one end of the sump, there are mangrove trees, and I´m sure with the way they are growing they are sucking up nitrates like a sponge, which I consider my primary objective ( to use nitrate between water changes) once a tank is cycled.

And I just really like mangroves.

Some foliage is reaching 6 feet above the sumps water surface.

Of course because my tanks and sumo are outside, space is of little concern.

And I agree thth Swiss tropicals accessment, with their foam panels acting as a wall, any need for extra bio-media seems a bit superflous.

On one end of the sump, there are mangrove trees, and I´m sure with the way they are growing they are sucking up nitrates like a sponge, which I consider my primary objective ( to use nitrate between water changes) once a tank is cycled.

And I just really like mangroves.

Some foliage is reaching 6 feet above the sumps water surface.

Of course because my tanks and sumo are outside, space is of little concern.

Last edited: