I have been building acrylic tanks off and on now for around 8 years. There are probably 50-100 of my tanks floating around Ontario. A few years back I ordered around 46 sheets of 3/4” material as a friend and I were going to do a stingray breeding project consisting of 10 480 gallon tanks. The idea later transitioned into a coral farm which seemed more profitable at the time due to the decreasing ray prices. Neither plan ended up happening as life got in the way. So I sat on a lot of acrylic for a few years doing occasional off and on jobs. Currently we have 30 sheets left.

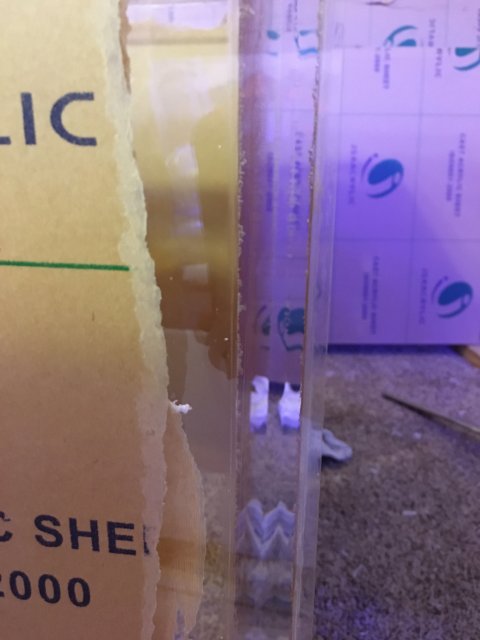

I recently got a new full time job just after graduating university which moved me into an apartment. This has hindered my ability to build tanks whenever I please. Most of my recent work has involved small builds and repairs. I recently said to myself “f*** it, I have been doing wood work in this apartment for almost a year now, never once got a noise complaint. I can get away with building a few tanks here and there. So I took 6 sheets up with me and started working. I’m currently on tank #3. The process is messy and I do plan to get the entire apartment professionally cleaned when all work is done. This thread will briefly go over a few of the builds, some tricks to working with acrylic and what I will personally get out of all this work. First two pics show some of the acrylic with a built 120 gallon, and the router/cutting room in the apartment.

I recently got a new full time job just after graduating university which moved me into an apartment. This has hindered my ability to build tanks whenever I please. Most of my recent work has involved small builds and repairs. I recently said to myself “f*** it, I have been doing wood work in this apartment for almost a year now, never once got a noise complaint. I can get away with building a few tanks here and there. So I took 6 sheets up with me and started working. I’m currently on tank #3. The process is messy and I do plan to get the entire apartment professionally cleaned when all work is done. This thread will briefly go over a few of the builds, some tricks to working with acrylic and what I will personally get out of all this work. First two pics show some of the acrylic with a built 120 gallon, and the router/cutting room in the apartment.