As per the title. Will silicone adhesive bond to epoxy / pond armor as well as glass?

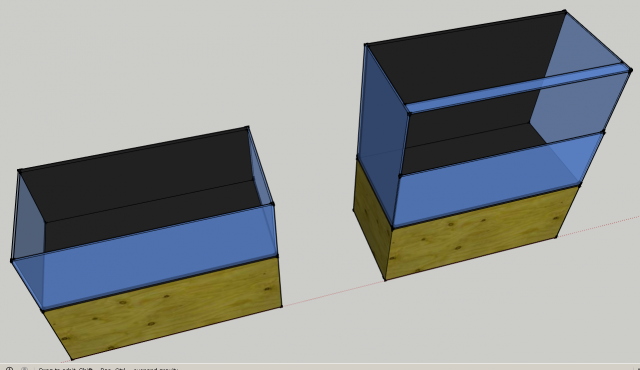

To give you an example of intended use:

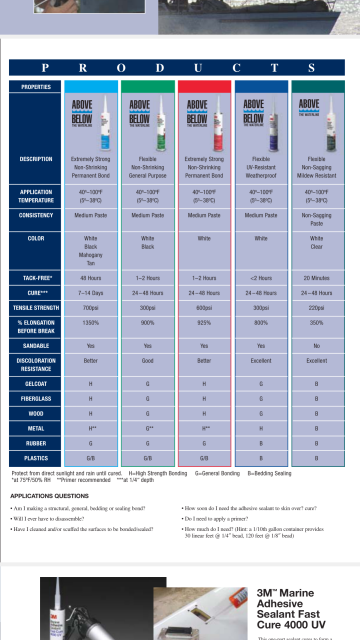

If i where to use either a heavy duty epoxy (the kind of stuff used for boats), or pond armor to coat and seal a plywood base and back panel, could i then use a 'top end' silicone adhesive to assemble glass panels to them (as if it where a regular glass aquarium build)?

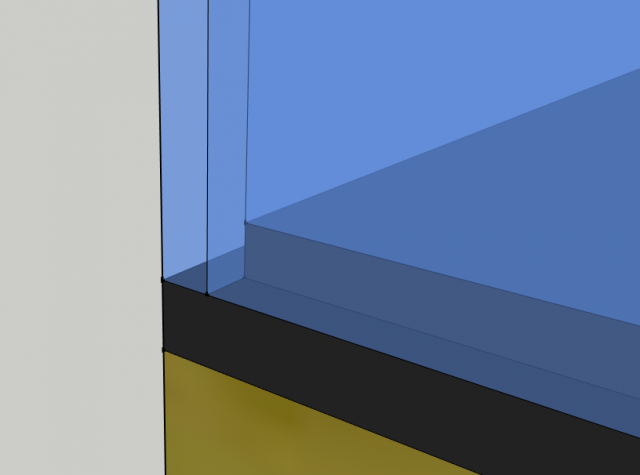

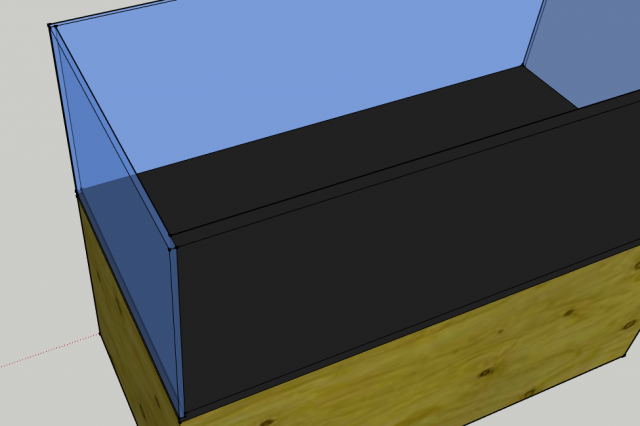

I was thinking to use a very thick ply (1.5-2") so it doesn't flex. Depending on the assembly method that could also increase the surface area for adhesive. Also, to use a thicker than usual bead of silicone to account for differing expansion rates. As far as i can tell it would basically all boil down to the bond between silicone and epoxy, and between epoxy and wood.

Why? I don't want a glass base unless i have to. Not for cost, but for durability and versatility. This build method would also be simple. If it would work for the base, why not do the back panel too and get the same benefits.

That is unless there are other materials that will bond to glass better (maybe GRP or modern composites?).....

I have seen the plywood bases with a rim around them to mechanically hold the glass, but i am not keen on that route for this particular build due to the extra bulk and the (presumed) small tolerances for differing expansion/contraction rates of glass and wood. Plus i was reading reference to plywood tanks being bonded together with silicone (no screws!) and reportedly holding up without issue. So i guess it might not be so crazy or stupid.

To give you an example of intended use:

If i where to use either a heavy duty epoxy (the kind of stuff used for boats), or pond armor to coat and seal a plywood base and back panel, could i then use a 'top end' silicone adhesive to assemble glass panels to them (as if it where a regular glass aquarium build)?

I was thinking to use a very thick ply (1.5-2") so it doesn't flex. Depending on the assembly method that could also increase the surface area for adhesive. Also, to use a thicker than usual bead of silicone to account for differing expansion rates. As far as i can tell it would basically all boil down to the bond between silicone and epoxy, and between epoxy and wood.

Why? I don't want a glass base unless i have to. Not for cost, but for durability and versatility. This build method would also be simple. If it would work for the base, why not do the back panel too and get the same benefits.

That is unless there are other materials that will bond to glass better (maybe GRP or modern composites?).....

I have seen the plywood bases with a rim around them to mechanically hold the glass, but i am not keen on that route for this particular build due to the extra bulk and the (presumed) small tolerances for differing expansion/contraction rates of glass and wood. Plus i was reading reference to plywood tanks being bonded together with silicone (no screws!) and reportedly holding up without issue. So i guess it might not be so crazy or stupid.