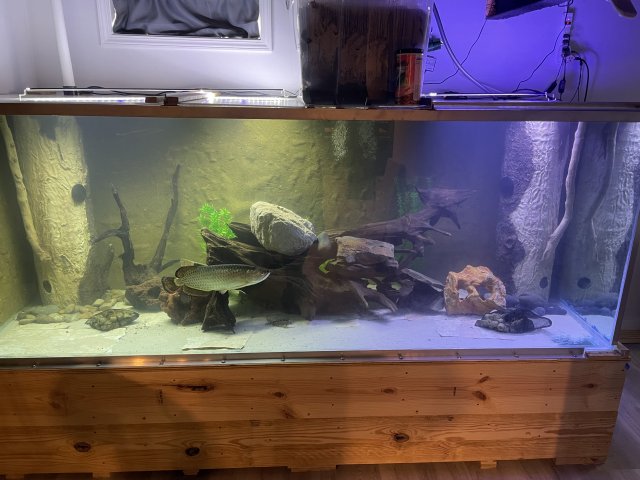

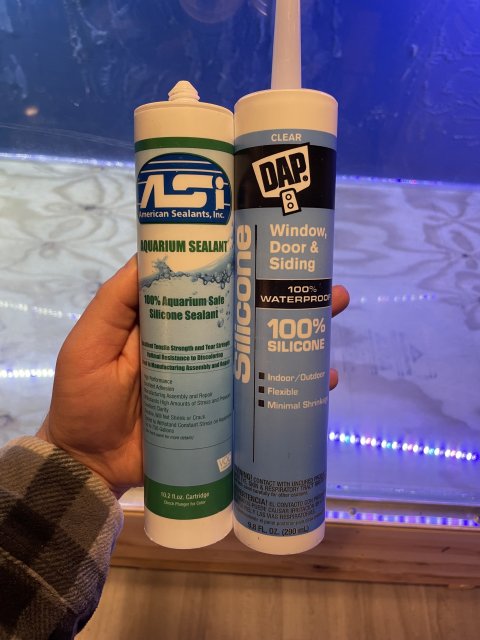

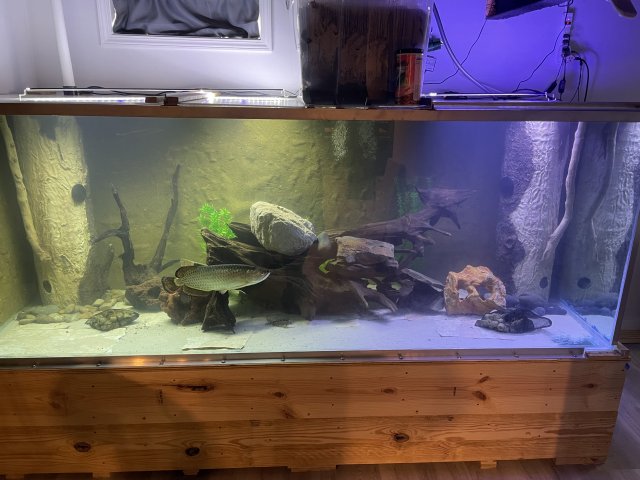

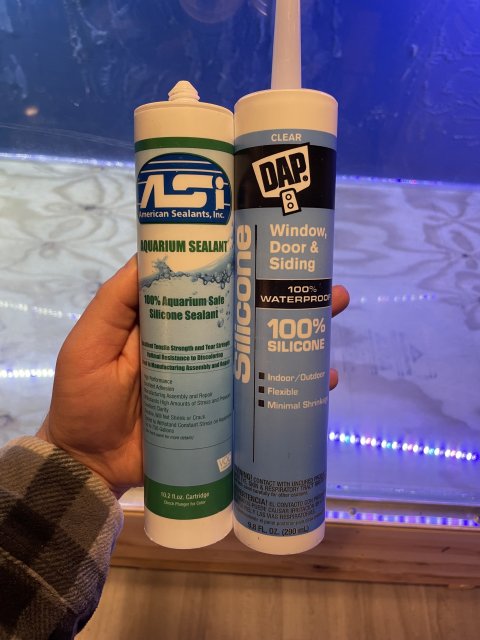

Hey everybody! I purchased a used 102x38x38x "3/4" (closer to 1/2") tempered glass aquarium. Tank/stand are completely level. Tank was built on Jan 31st of 2023. Tank sat until I could get the stainless steel brace for the top welded and installed (May 11th of 2023). It had plenty of cure time. Tank was slowly filled from May and I added water every week until it was full in June sometime. Drained the tank and installed the background and decor. This also took some time to get and do. Tank was full and ready by the 20th of August and had its first fish in there on August 27th. October 7th 2023 is the day it leaked. I've used DAP silicone in the past to reseal a 30" tall 150 gallon. I'm hoping it was due to this silicone and nothing to do with the build. There is a picture of the silicone when we got in the tank after it was all dried and you can see the silicone was cracked.

We resealed the tank on the 16th of December using ASI silicone. Wondering if anyone had any advice or feedback. I plan on waiting until January 13th to refill which gives us 28 days of cure time. It was a thick bead of silicone..

We resealed the tank on the 16th of December using ASI silicone. Wondering if anyone had any advice or feedback. I plan on waiting until January 13th to refill which gives us 28 days of cure time. It was a thick bead of silicone..