Would love some feedback on my 180 gallon sump design for my 720 plywood build (see full build thread in DIY section if interested!  )

)

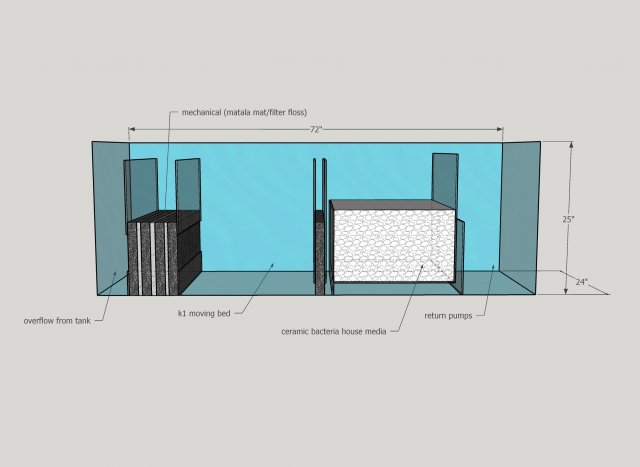

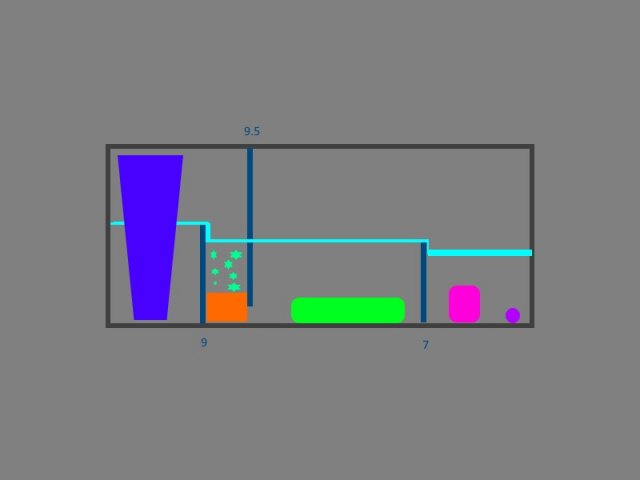

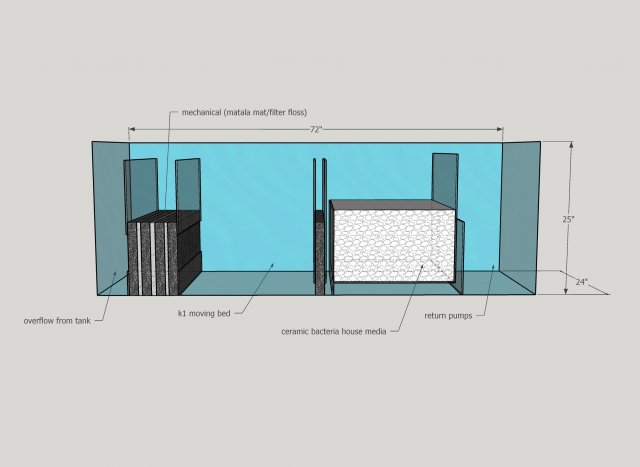

Decided to try a horizontal mechanical filtration using matala/jap mat with filter floss sandwiched between. This will be followed by a k1 moving bed using matala mat as the barriers on each side. Last will be more bio filtration with ceramic bacteria house media.

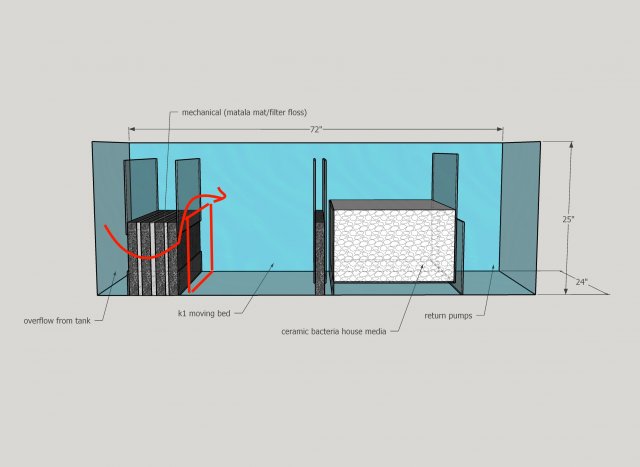

My only concern is the k1 section not having enough water volume. May need to modify direction of flow/baffle placement.

Any thoughts/comments?

Decided to try a horizontal mechanical filtration using matala/jap mat with filter floss sandwiched between. This will be followed by a k1 moving bed using matala mat as the barriers on each side. Last will be more bio filtration with ceramic bacteria house media.

My only concern is the k1 section not having enough water volume. May need to modify direction of flow/baffle placement.

Any thoughts/comments?