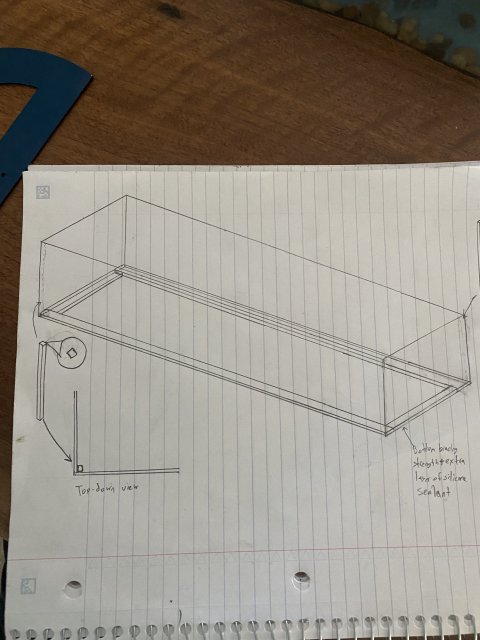

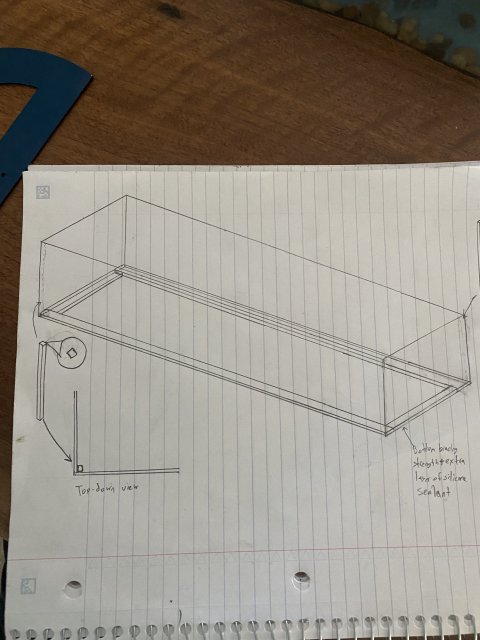

As long as your glass is sufficiently thick for the dimensions of your build...and I would always recommend going thicker than absolutely necessary...I'm not sure you will achieve anything positive. You will have an exterior angle running all around the inside of your tank, inviting chipping and other damage. It might indeed add an extra layer of confidence to your waterproofing, but in a properly-constructed tank this is not needed. If you are concerned with the life of the silicone, doing this, i.e. adding even more silicone, won't make the stuff last any longer. It will, however, make it exponentially more difficult to re-seal at any future point. You will literally be doubling the amount of old silicone bead that must be laboriously removed before a new bead is laid down.

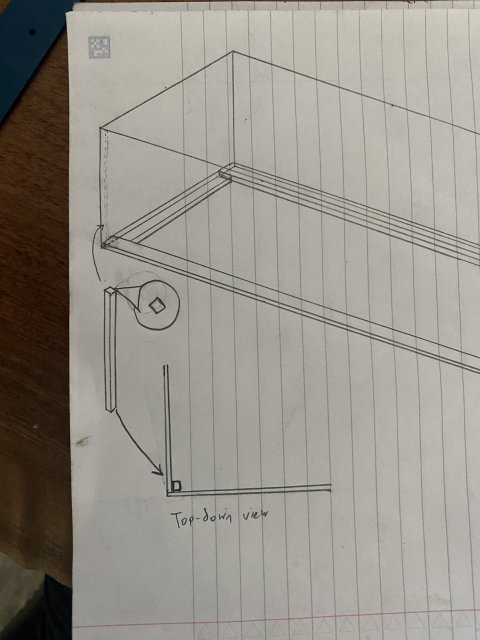

The biggest negative, IMHO, is the difficulty of construction. I don't know how much experience you have building all-glass tanks; they are not difficult per se, but assembling one is a time-sensitive operation. You need to get the whole thing put together in as few minutes as possible, as all the silicone needs to be laid down more-or-less continuously to achieve a waterproof construction. The glass goes together and then the interior bead needs to be smoothed all at once, before the stuff starts to set up. If you build it with this interior bracing...the same applies...except you will need to assemble the tank, making sure that enough silicone squeezes out to then lay the bracing into (or else lay down another bead for this purpose), then install all the bracing, and then smooth out twice as many seams afterwards...all while making sure that nothing slides out of place in the process, in the relatively few minutes that you have before the silicone starts to surface skim.

The less experience you have, the closer this operation comes to being practically impossible. You could, I suppose, build the tank first, allow the silicone to cure, carefully scrape off all the squeezed-out internal bead right down to bare glass, and then add a fresh bead to all the interior angles and install the braces as a separate operation...but this will not give you the strength of construction that is achieved by doing it all at once, and all the other negatives are still in place. This is essentially re-sealing a tank...that was built only a week before. Seems a bit silly, doesn't it?

IMHO, if you want the best strength, durability and ease of construction...use thicker glass, forget about the braces.