First a quick shout out to everyone who has put their wood aquarium plans & pics for all to see. I think this a fantastic community, and I hope we can continue to help each other to build better and bigger tanks!

That being said, there is a huge difference between a 600 gal tank and a 50,000 gal tank. Since a 600 gal seems to be more approachable for most, I'd like to focus on that size (range), and the use of plywood/wood for construction.

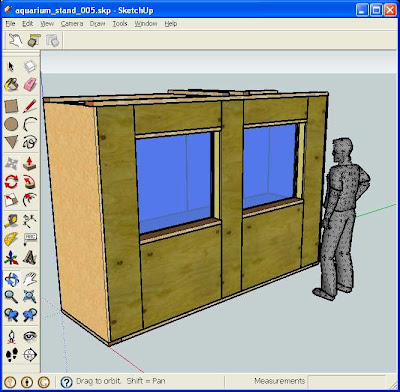

A great suggestion (I think it was Gator) was to use Google's free SketchUp program. I started my 10x3x4 aquarium plans on graph paper, and it was going smoothly. But I was BLOWN AWAY by using SketchUp. Being able to see the structure in 3D as you draw it is priceless. If you are a DIY person, then SketchUp is something you can not live without.

---

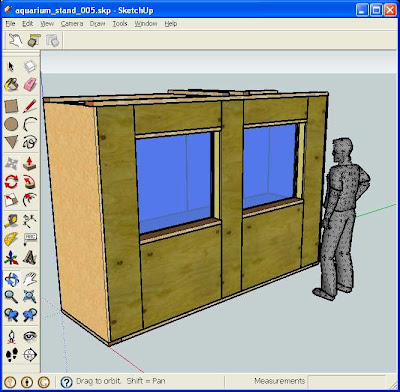

So using SketchUp, here is the "rough draft" of the tank I'm looking to build.

A couple of ideas: I've used the basic 2x4 wall construction to create a very strong frame by using inexpensive (ish) materials. The plywood is 3/4" exterior grade stuff, the lumber is mostly 2x4 with a couple 2x6. The glass was divided into 2 sheets, 42x48 inches each, to cut down on cost.

The only "high" end item is the interior plywood, which I'm thinking will be 3/8" furniture grade (no filling required!).

---

The other main point is to be able to build this whole project with a circular saw and a couple NEW blades (about $7 a pop, but sharp is key to smooth cuts). I'll use a straight edge and 2 quick clamps to run my circ saw along for (hopefully) perfect cuts.

It's a lot of wood, but it's all cheap wood. I haven't done the math on it, but he strength of the structure should be able to support 10 times the weight of the water, etc. Should hold up pretty well to earthquakes too (well, mild ones anyway).

---

So here are the screen shots of the design:

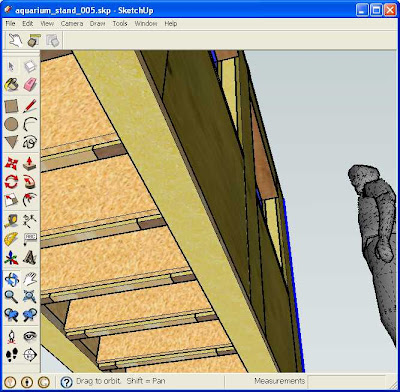

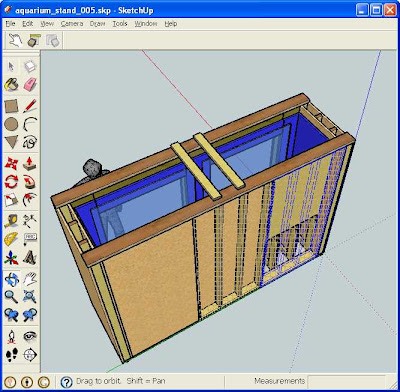

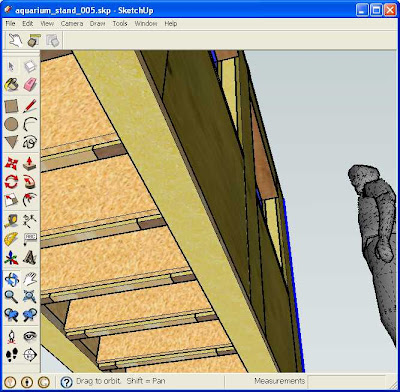

A shot of the corner support. Note in the right front of this pic the 2x4 supports the 3/4" ply on both axis.

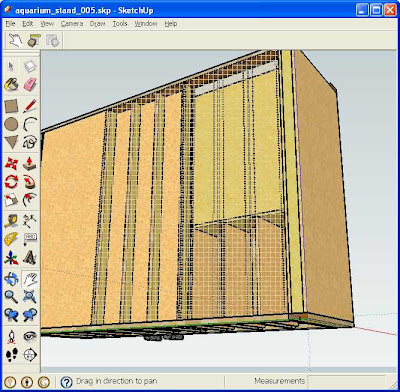

Shows the back left corner detail. The 2x4's are positioned to support every junction of the 3/4" plywood. The "furniture grade 3/8" ply is glued to the 3/4" ply.

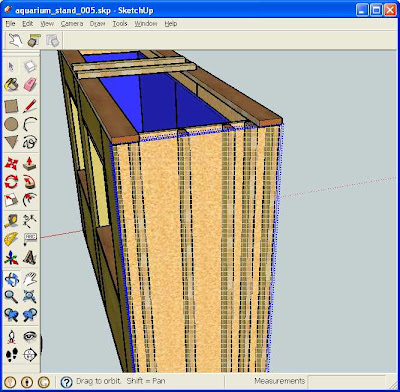

A view of the back showing different transparencies. All the 2x4's are 12" on center. It may be overkill to not go with 14" or 16" on center, but is only a bit more wood (cheap 2x4's) giving a lot more rigidity.

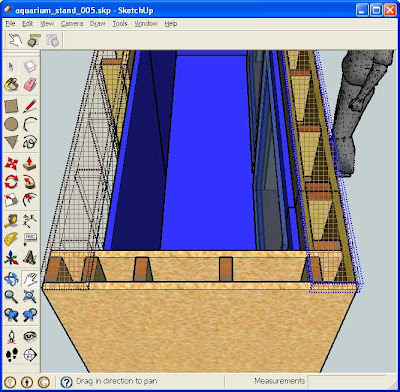

Same section as above, shown looking down.

Shot looking thru the front "2x4 ply sandwich" to the under-tank supports.

These 2x4 vertical supports are 14" on center. The top is a 2x6. The sides are 3/4" plywood.

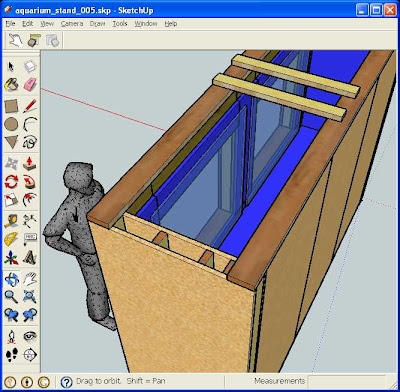

Shows the bottom "support structure" for the weight of the water. Each rib is 3/4" plywood with 2x4 running around the outside edge. All 2x4 are "screwed and glued" (2" wood decking screws, waterproof glue). These ribs are placed 12" on center.

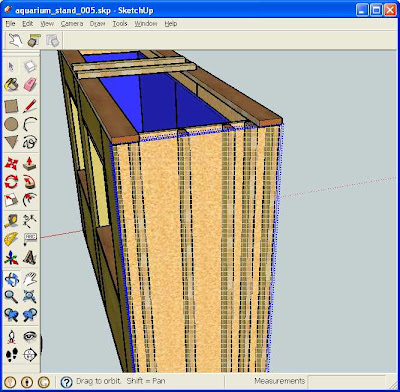

Shows the 2x4 structure of the side walls. The 2x4's are sandwiched between two 3/4" plywood sheets running bottom to top (for rigidity and strength).

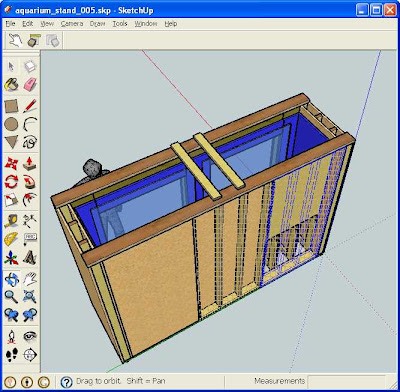

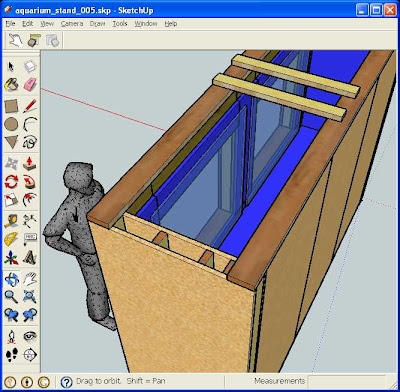

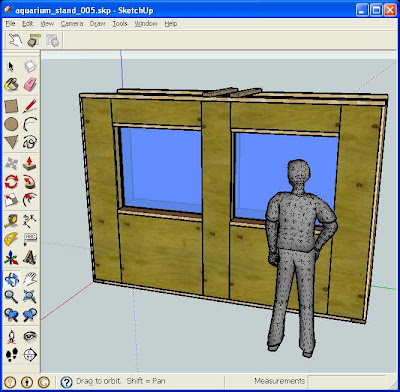

This top view shows the interior. The blue (non-translucent) is "furniture grade" plywood (3/8"). The translucent fronts are 2 glass panes, 42x48 each.

Front right. The idea of using two planes of glass came from several sources (including this forum). The Waikiki aquarium has a few tanks setup that way too. But mostly it was the size, weight, expense and structural requirements that nixed the single glass pane idea.

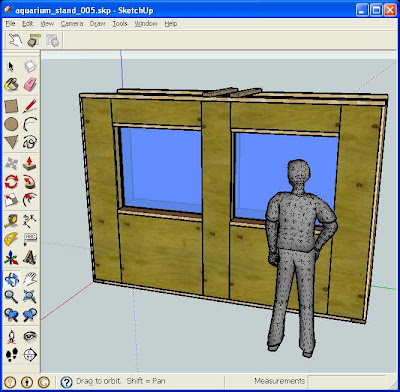

The front of the 10' tank. Depth is 42". Internal width is 29" (approx). Depth and width could be scaled out until the plywood shown on the far left reached 48" in width (it is 37.5" in this design).

That being said, there is a huge difference between a 600 gal tank and a 50,000 gal tank. Since a 600 gal seems to be more approachable for most, I'd like to focus on that size (range), and the use of plywood/wood for construction.

A great suggestion (I think it was Gator) was to use Google's free SketchUp program. I started my 10x3x4 aquarium plans on graph paper, and it was going smoothly. But I was BLOWN AWAY by using SketchUp. Being able to see the structure in 3D as you draw it is priceless. If you are a DIY person, then SketchUp is something you can not live without.

---

So using SketchUp, here is the "rough draft" of the tank I'm looking to build.

A couple of ideas: I've used the basic 2x4 wall construction to create a very strong frame by using inexpensive (ish) materials. The plywood is 3/4" exterior grade stuff, the lumber is mostly 2x4 with a couple 2x6. The glass was divided into 2 sheets, 42x48 inches each, to cut down on cost.

The only "high" end item is the interior plywood, which I'm thinking will be 3/8" furniture grade (no filling required!).

---

The other main point is to be able to build this whole project with a circular saw and a couple NEW blades (about $7 a pop, but sharp is key to smooth cuts). I'll use a straight edge and 2 quick clamps to run my circ saw along for (hopefully) perfect cuts.

It's a lot of wood, but it's all cheap wood. I haven't done the math on it, but he strength of the structure should be able to support 10 times the weight of the water, etc. Should hold up pretty well to earthquakes too (well, mild ones anyway).

---

So here are the screen shots of the design:

A shot of the corner support. Note in the right front of this pic the 2x4 supports the 3/4" ply on both axis.

Shows the back left corner detail. The 2x4's are positioned to support every junction of the 3/4" plywood. The "furniture grade 3/8" ply is glued to the 3/4" ply.

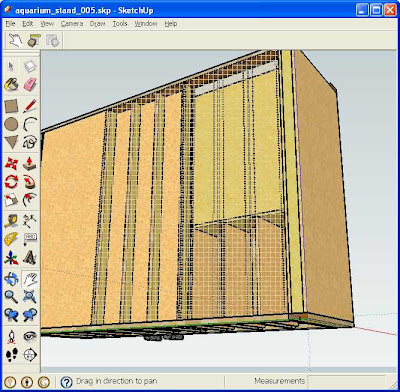

A view of the back showing different transparencies. All the 2x4's are 12" on center. It may be overkill to not go with 14" or 16" on center, but is only a bit more wood (cheap 2x4's) giving a lot more rigidity.

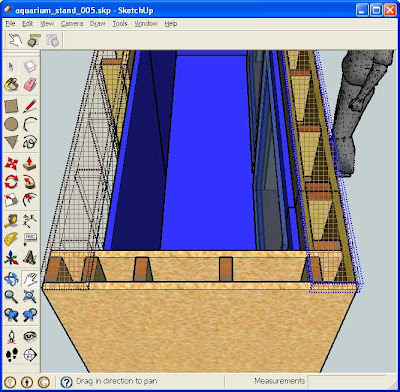

Same section as above, shown looking down.

Shot looking thru the front "2x4 ply sandwich" to the under-tank supports.

These 2x4 vertical supports are 14" on center. The top is a 2x6. The sides are 3/4" plywood.

Shows the bottom "support structure" for the weight of the water. Each rib is 3/4" plywood with 2x4 running around the outside edge. All 2x4 are "screwed and glued" (2" wood decking screws, waterproof glue). These ribs are placed 12" on center.

Shows the 2x4 structure of the side walls. The 2x4's are sandwiched between two 3/4" plywood sheets running bottom to top (for rigidity and strength).

This top view shows the interior. The blue (non-translucent) is "furniture grade" plywood (3/8"). The translucent fronts are 2 glass panes, 42x48 each.

Front right. The idea of using two planes of glass came from several sources (including this forum). The Waikiki aquarium has a few tanks setup that way too. But mostly it was the size, weight, expense and structural requirements that nixed the single glass pane idea.

The front of the 10' tank. Depth is 42". Internal width is 29" (approx). Depth and width could be scaled out until the plywood shown on the far left reached 48" in width (it is 37.5" in this design).