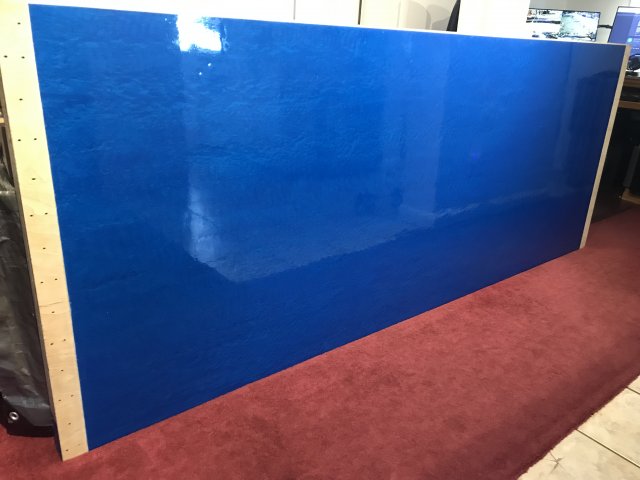

I got the 3/4" glass moved into my home and I will be installing it into my aquarium after I assemble it. Question is will the glass fit through the opening or will I have to go over the top? The glass took 4 people to safely move at 230 lbs. I have 8 heavy duty glass suction cups for 4 men to move it which made it fairly easy but lifting the glass up 64" and into the aquarium would be at best scary and someone could get hurt . I'm

not a math wizard and I need someone to do some calculation to see if the glass will fit through the opening. The aquarium is 8ft long, 4ft from front to back with a (2 inch wall thickness). The opening for the glass is 87 inches x 30 inches and the glass has a 2 inch overlap all the way around.

I know the glass will have to be tilted to get it through but will it be to long to get it into the aquarium? If nobody can give me a answer I will have to make a cardboard template of the glass and see if it will fit through the opening once the aquarium is assembled. Things like this keep me up at night and that's why I'm asking. I'm a person that thinks about my project and does research before making a costly move that I've never done before. Any help will allow me to get some decent sleep. Thanks in advance.

not a math wizard and I need someone to do some calculation to see if the glass will fit through the opening. The aquarium is 8ft long, 4ft from front to back with a (2 inch wall thickness). The opening for the glass is 87 inches x 30 inches and the glass has a 2 inch overlap all the way around.

I know the glass will have to be tilted to get it through but will it be to long to get it into the aquarium? If nobody can give me a answer I will have to make a cardboard template of the glass and see if it will fit through the opening once the aquarium is assembled. Things like this keep me up at night and that's why I'm asking. I'm a person that thinks about my project and does research before making a costly move that I've never done before. Any help will allow me to get some decent sleep. Thanks in advance.