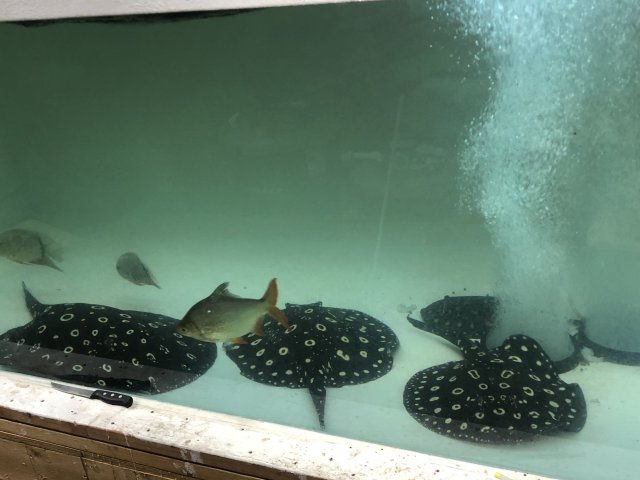

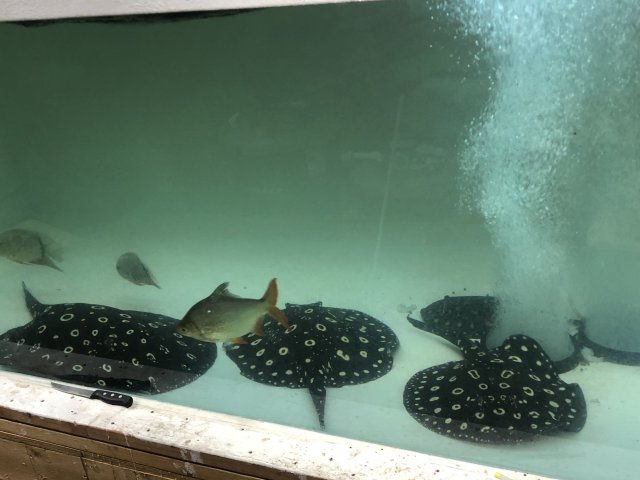

This whole tank was built with one stingray in mind! While it holds others, I mainly built it for My Black Diamond female at 24” Disc she is a true monster so I decided she deserved a monster tank and to give my 8x4x2 (her old tank) to the marble motoros.

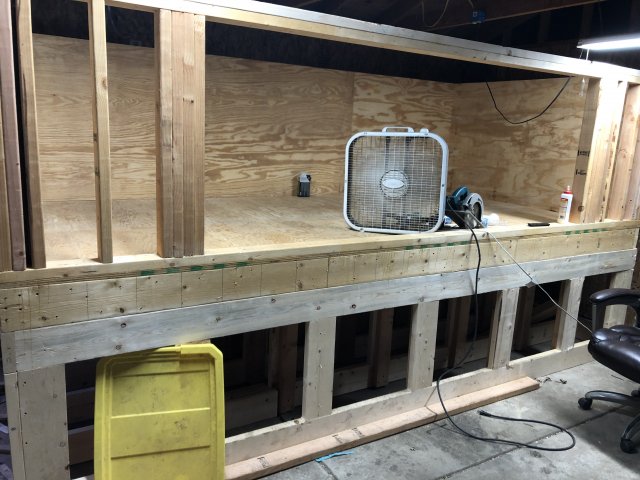

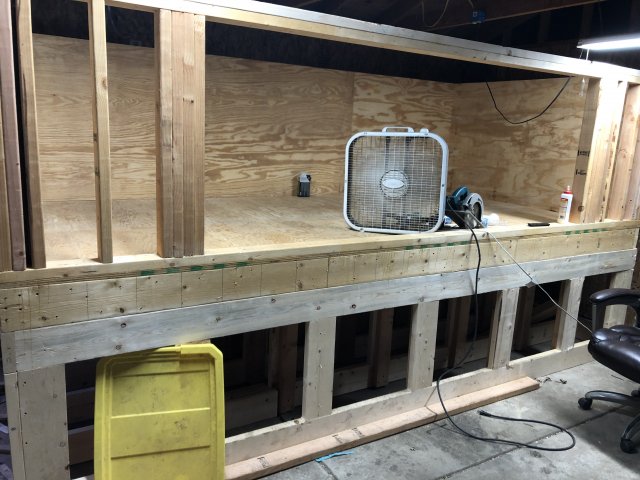

The tank dimensions are 12’x6’x3’. Gathering lumber and building the bottom base of the tank. Everything is glued and screwed with 2x6s. I did 8” on center for each 2x6 since I plan On moving one day I’d like this thing to be bullet proof and not tweak when I go to move.

I quickly decided I would build a stand for it for viewing purposes and to level the tank out easier.

Here I’m Getting the base on the stand and starting to build the sides. I never got pics of me sheeting the base but it’s pretty simple I just glued it to all the base supports and glued the seams and pre drilled and screwed it every other 2x6 support. You never realize how expensive screws are until you start using hundreds of them

Getting the sides up and level was a pain being alone and trying to screw them but I got it done! Sheeting wasn’t to bad just time consuming pre drilling everything so the wood doesn’t split. Also my White German Shepherd being nosey

Filling in screws holes and sanding. My least favorite part. My whole fish room was a dust mess.

Fiberglassing the seams. I HIGHLY recommend this. I’ve seen a lot of tanks fail at the seams when doing my research. Very glad I did this. Cost me less then $50 for this big tank. Don’t skip this.

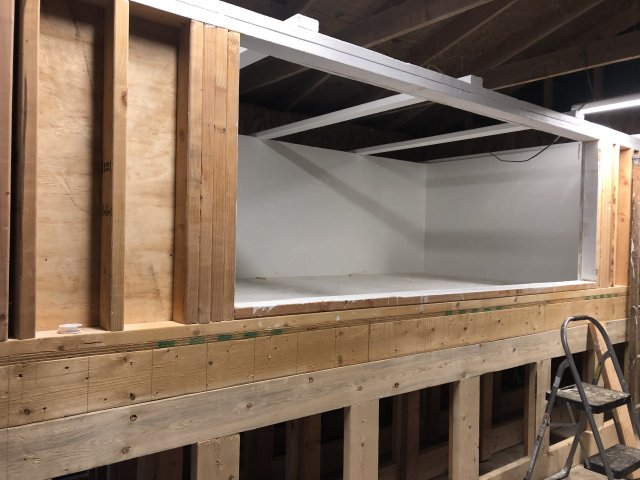

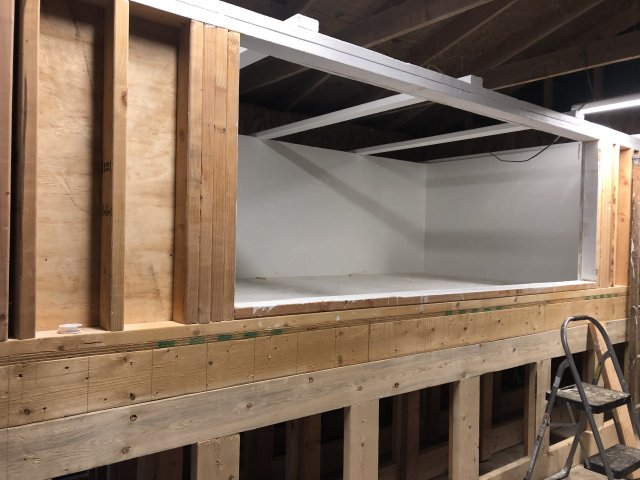

Now the part were it was finally starting to feel like a fish tank. Epoxying it ?. For this I used Interseal 670hs you can get 5gallons for $180 U.S. they sell this stuff world wide! Look into it if your going plywood. Pond armor is a rip off! This stuff is tried and proven by many monster fish keepers with big builds. I also added the bracing in after putting a couple coats on the bottom and walls since I won’t be climbing in and out as much now.

Installing the window. I used asi aquarium silicone. It has strength properties in it and the 3/4” window is 500lbs so I didn’t wanna skimp on it. Ordered it from glasscages.com even with freight shipping it was cheaper then buying local

Finally after waiting a week for the silicon to cure I am adding water ? there was no filling this thing fast. It took 8hrs with my valve open wide.

The rays going in now and more to come ? no lights on tank yet

It has been going strong for two months now. I will soon be insulating and wrapping it to make it look presentable just didn’t want a drip or something to happen and me have to unwrap it to see where it’s leaking. If your looking for a lot of space for little money I’d say plywood tank is for you! If you can find a used piece of glass before you start building it do it! You will save a TON of money and be motivated to work on your build! I’ve seen a lot of tanks go ghost once it comes to installing the glass. Probably because most make them tall and then check into the glass prices and see that the thick glass they need is crazy expensive.

Thanks for checking out my build! Will be posting updates soon.

The tank dimensions are 12’x6’x3’. Gathering lumber and building the bottom base of the tank. Everything is glued and screwed with 2x6s. I did 8” on center for each 2x6 since I plan On moving one day I’d like this thing to be bullet proof and not tweak when I go to move.

I quickly decided I would build a stand for it for viewing purposes and to level the tank out easier.

Here I’m Getting the base on the stand and starting to build the sides. I never got pics of me sheeting the base but it’s pretty simple I just glued it to all the base supports and glued the seams and pre drilled and screwed it every other 2x6 support. You never realize how expensive screws are until you start using hundreds of them

Getting the sides up and level was a pain being alone and trying to screw them but I got it done! Sheeting wasn’t to bad just time consuming pre drilling everything so the wood doesn’t split. Also my White German Shepherd being nosey

Filling in screws holes and sanding. My least favorite part. My whole fish room was a dust mess.

Fiberglassing the seams. I HIGHLY recommend this. I’ve seen a lot of tanks fail at the seams when doing my research. Very glad I did this. Cost me less then $50 for this big tank. Don’t skip this.

Now the part were it was finally starting to feel like a fish tank. Epoxying it ?. For this I used Interseal 670hs you can get 5gallons for $180 U.S. they sell this stuff world wide! Look into it if your going plywood. Pond armor is a rip off! This stuff is tried and proven by many monster fish keepers with big builds. I also added the bracing in after putting a couple coats on the bottom and walls since I won’t be climbing in and out as much now.

Installing the window. I used asi aquarium silicone. It has strength properties in it and the 3/4” window is 500lbs so I didn’t wanna skimp on it. Ordered it from glasscages.com even with freight shipping it was cheaper then buying local

Finally after waiting a week for the silicon to cure I am adding water ? there was no filling this thing fast. It took 8hrs with my valve open wide.

The rays going in now and more to come ? no lights on tank yet

It has been going strong for two months now. I will soon be insulating and wrapping it to make it look presentable just didn’t want a drip or something to happen and me have to unwrap it to see where it’s leaking. If your looking for a lot of space for little money I’d say plywood tank is for you! If you can find a used piece of glass before you start building it do it! You will save a TON of money and be motivated to work on your build! I’ve seen a lot of tanks go ghost once it comes to installing the glass. Probably because most make them tall and then check into the glass prices and see that the thick glass they need is crazy expensive.

Thanks for checking out my build! Will be posting updates soon.