I wanted to pause my build to gather structure design ideas from fellow DIY hobbyist who already completed a similar size build.

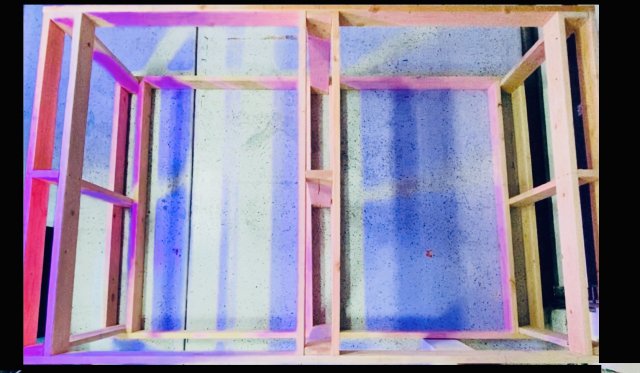

The stand will be constructed from 2x6 material and 2x4s for the tank dimensions. The space below will be for a combo sump and Ultima set up.

The goal is to be able to support a max weight capacity of 20,400kg/44,969lbs.

5100L| 3048x1829x914mm | 5,100kg

1347 gal| 120x72x36in | 11,242 lbs

Thanks in advance.

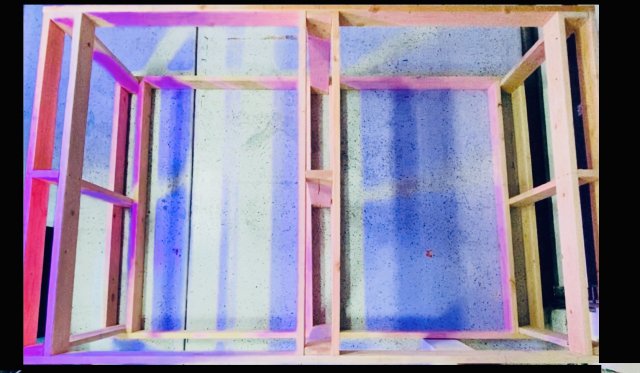

The stand will be constructed from 2x6 material and 2x4s for the tank dimensions. The space below will be for a combo sump and Ultima set up.

The goal is to be able to support a max weight capacity of 20,400kg/44,969lbs.

5100L| 3048x1829x914mm | 5,100kg

1347 gal| 120x72x36in | 11,242 lbs

Thanks in advance.