Im in the process of getting a new to me 470 gallon setup. Its 96x42x27 tall. 3/4" glass. Euro braced with 2 18" braces from front to back panels ontop. It is setup with 2 - 1" bulkheads and a 2" bulkhead on the bottom pane against the back wall.

I got the tank/stand/sump from a guy, he bought it off another person, it had to be cut apart to get out of that house and then was rebuilt at his place.

He never got to use it, it was rebuilt 2 months ago and never filled. He says it was setup just as I have it now from the guy he got it from.

The big question i have is the steel stand doesn't have any cross braces on the top, apparently never did and I don't even see how I could fit one anyway with the drains coming down in the middle. The tank is sitting on 3/4" plywood (not just the cheap stuff) and really good foam.

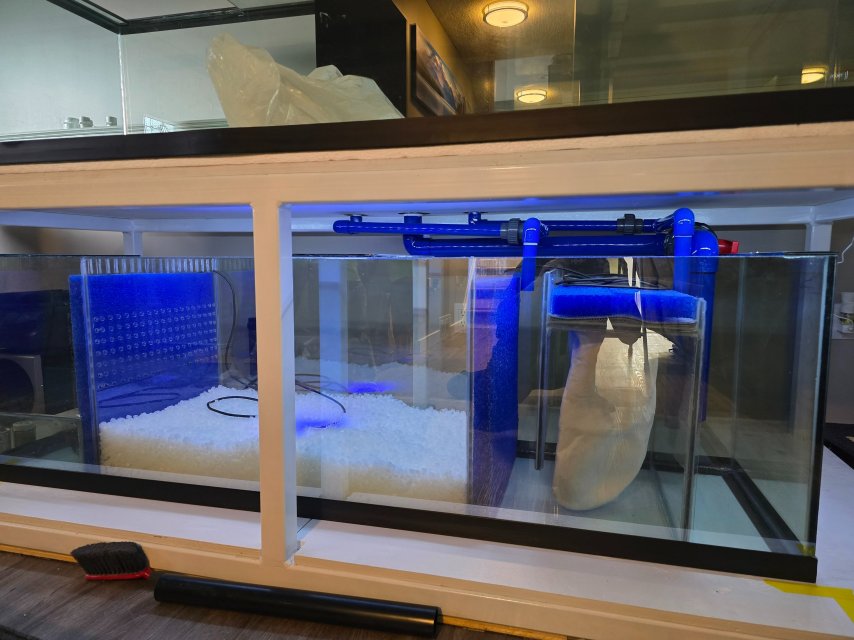

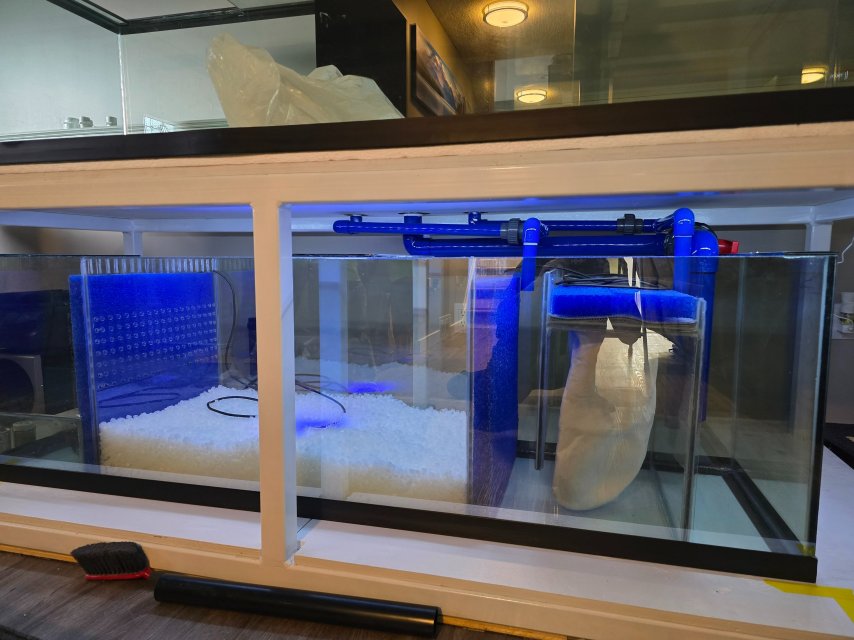

Ive spent the past month building the sump the way I want, getting all the plumbing done, and im about ready to fill it this week. It has just bothered me a bit and before I start filling i figured id get some second opinions of whether or not this stand with no cross brace at the top is going to be okay as far as the bottom pane of glass possibly having extreme deflection? I'd really hate for the bottom pane to Crack as this tank is just beautiful. Please any input is appreciated. Hopefully all my hard work wasn't for nothing now lol.

Pics of stand etc is there to see.

I got the tank/stand/sump from a guy, he bought it off another person, it had to be cut apart to get out of that house and then was rebuilt at his place.

He never got to use it, it was rebuilt 2 months ago and never filled. He says it was setup just as I have it now from the guy he got it from.

The big question i have is the steel stand doesn't have any cross braces on the top, apparently never did and I don't even see how I could fit one anyway with the drains coming down in the middle. The tank is sitting on 3/4" plywood (not just the cheap stuff) and really good foam.

Ive spent the past month building the sump the way I want, getting all the plumbing done, and im about ready to fill it this week. It has just bothered me a bit and before I start filling i figured id get some second opinions of whether or not this stand with no cross brace at the top is going to be okay as far as the bottom pane of glass possibly having extreme deflection? I'd really hate for the bottom pane to Crack as this tank is just beautiful. Please any input is appreciated. Hopefully all my hard work wasn't for nothing now lol.

Pics of stand etc is there to see.