Well now that I am ready to start the fun, I decided to create a new thread dedicated to my tank setup. I will give the background again, but really need helping with the plumbing so all experts please share your wisdom!

Tank

- Acrylic tank from fishtankdirect.com but built by Suncoast Aquariums which is a "sister" company essentially.

- The tank will be 94in x 48in x 30in (high)

- Tank is due to arrive some time next week but here are some pics they sent me. It has been great dealing with these guys so far.

- I will be getting a steal stand courtesy of fellow MFKer jsodwi

who has also awesome and tolerate of my many messages and texts

jsodwi

who has also awesome and tolerate of my many messages and texts

- The plan is to go bare bottom to minimize maintenance. I will mostly likely paint the bottom black

Filtration

- Two corner 9in HMF filters run via powehead (essentially backup filtration plus to help hide equipment)

- Ultima II 1,000 w/ reeflo gold super dart (essentially primary filtration but really wanted it for backflush capabilities)

- The HMF will be running at about 1500 gph (3 times turnover) and the ultima will be around 1,000 gph giving me 2,500 gph / 5 times turnover

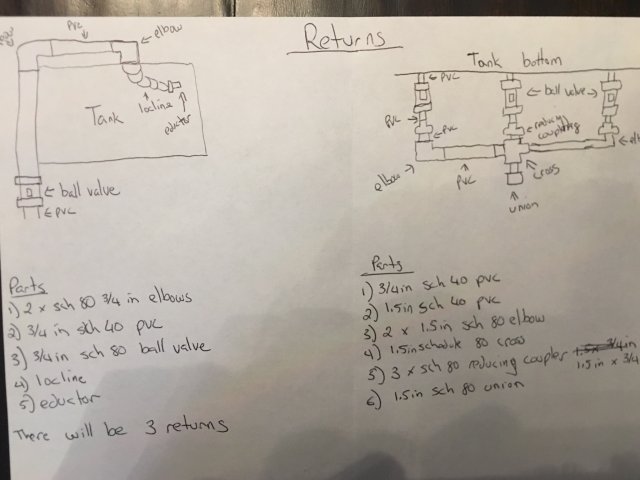

- Internal to the tank, I am adding eductors to the ultima lines via the loc lines. The eductors increase flow up to 4x which means I will be getting about 4,000 gph (keep in mind this is just in tank flow and does not impact turnover through the filter)

- Cold water drip running about 50g a day

Inhabitants

- Single 15-16in aimara wolf fish, but hope to maybe add something else one day

Plumbing

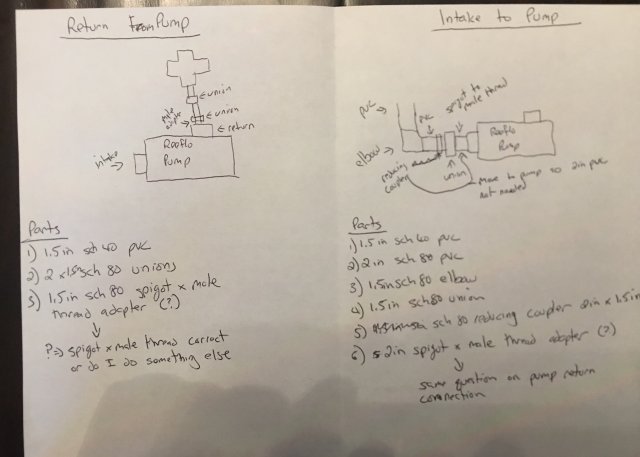

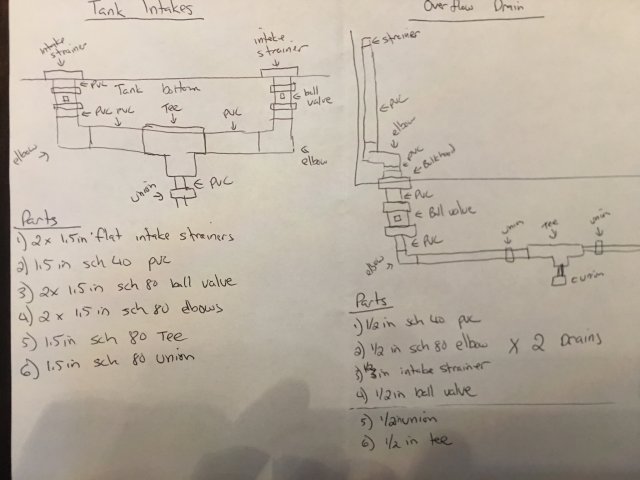

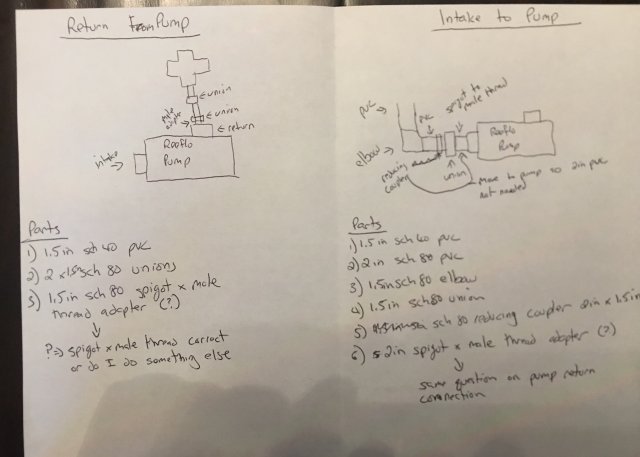

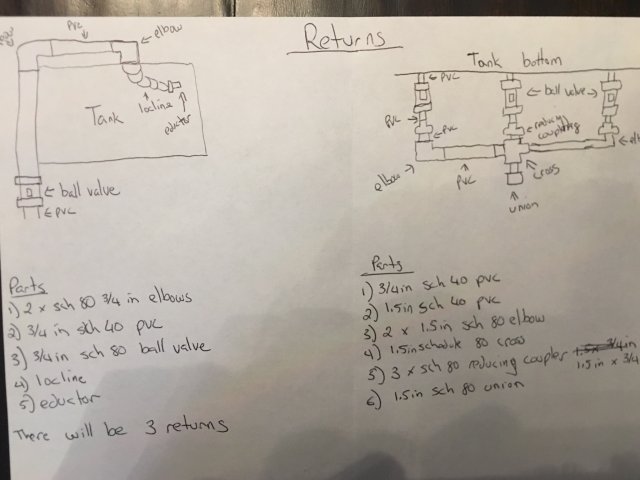

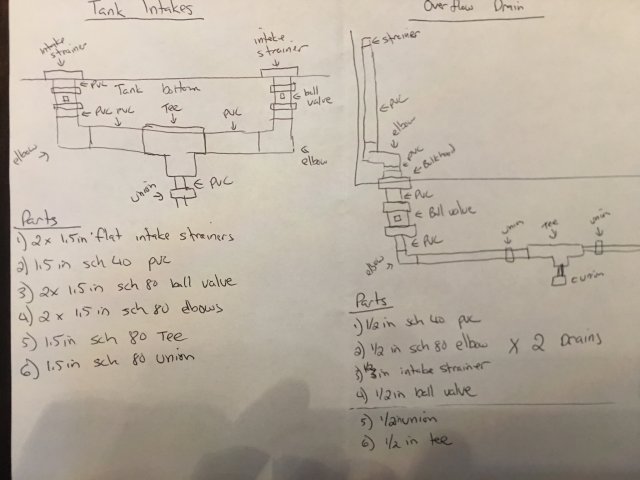

- I am doing a mix of sch 40 in black and sch 80 in gray. The tank is in my family room, and I was thinking of leaving the stand exposed because it can give an awesome wow factor. However, that means I want it to look extremely clean.

- I needed to go with sch 80 plumbing for all elbows, Tees, ball valves, etc because you cannot get sch 40 in black

- Drawings are not to scale nor accurate via sizing, but focused on identifying where I am running valves, elbows, tees, etc.

Here is where I need help!!! JK47

JK47

mrrobxc

. Below are pics of drawings of all my planned plumbing. I have laid this out so others that are as bad with their hands can see my logic and maybe learn. I also have some really important questions that I would like to get answered.

mrrobxc

. Below are pics of drawings of all my planned plumbing. I have laid this out so others that are as bad with their hands can see my logic and maybe learn. I also have some really important questions that I would like to get answered.

1) What pvc cement should I get (are there colored versions that go better with black/gray plumbing). I am planning on using pipe thread sealant on the reeflo pump

2) JK47 - When connecting plumbing to the reeflo so I use a spigot x male thread connector? You used a nipple that you did not recommend. The spigot I am assuming I can connect to the union direct and the male thread to the pump

3) Does it matter where I put the Tee or Cross for splitting lines? I planned on putting them as close to the tank as possible

4) If I use ball valves do I need unions? Looks like the ball valves act as unions also? I am planning on using lots of unions which you will see in my drawings but not sure they are needed by the ball valves.

5) When I cut pvc, do I need to sand it? Is there a best way to cut it?

6) Do I need to support parallel lines of pvc? I am assuming yes.

Here are the pics. I have already ordered a ton of PVC but need to order the rest. I am ordering everything from bulkreefsupply essentially as their prices aren't bad and they allow for free returns. This way I just order a ton. Please feel free to ask questions, or provide any feedback.

Tank

- Acrylic tank from fishtankdirect.com but built by Suncoast Aquariums which is a "sister" company essentially.

- The tank will be 94in x 48in x 30in (high)

- Tank is due to arrive some time next week but here are some pics they sent me. It has been great dealing with these guys so far.

- I will be getting a steal stand courtesy of fellow MFKer

- The plan is to go bare bottom to minimize maintenance. I will mostly likely paint the bottom black

Filtration

- Two corner 9in HMF filters run via powehead (essentially backup filtration plus to help hide equipment)

- Ultima II 1,000 w/ reeflo gold super dart (essentially primary filtration but really wanted it for backflush capabilities)

- The HMF will be running at about 1500 gph (3 times turnover) and the ultima will be around 1,000 gph giving me 2,500 gph / 5 times turnover

- Internal to the tank, I am adding eductors to the ultima lines via the loc lines. The eductors increase flow up to 4x which means I will be getting about 4,000 gph (keep in mind this is just in tank flow and does not impact turnover through the filter)

- Cold water drip running about 50g a day

Inhabitants

- Single 15-16in aimara wolf fish, but hope to maybe add something else one day

Plumbing

- I am doing a mix of sch 40 in black and sch 80 in gray. The tank is in my family room, and I was thinking of leaving the stand exposed because it can give an awesome wow factor. However, that means I want it to look extremely clean.

- I needed to go with sch 80 plumbing for all elbows, Tees, ball valves, etc because you cannot get sch 40 in black

- Drawings are not to scale nor accurate via sizing, but focused on identifying where I am running valves, elbows, tees, etc.

Here is where I need help!!!

1) What pvc cement should I get (are there colored versions that go better with black/gray plumbing). I am planning on using pipe thread sealant on the reeflo pump

2) JK47 - When connecting plumbing to the reeflo so I use a spigot x male thread connector? You used a nipple that you did not recommend. The spigot I am assuming I can connect to the union direct and the male thread to the pump

3) Does it matter where I put the Tee or Cross for splitting lines? I planned on putting them as close to the tank as possible

4) If I use ball valves do I need unions? Looks like the ball valves act as unions also? I am planning on using lots of unions which you will see in my drawings but not sure they are needed by the ball valves.

5) When I cut pvc, do I need to sand it? Is there a best way to cut it?

6) Do I need to support parallel lines of pvc? I am assuming yes.

Here are the pics. I have already ordered a ton of PVC but need to order the rest. I am ordering everything from bulkreefsupply essentially as their prices aren't bad and they allow for free returns. This way I just order a ton. Please feel free to ask questions, or provide any feedback.