Sorry to hear about your current resurgence of fresh problems, but...wow, this is a fantastic, informative and entertaining thread!

I recall back in about 1970, seeing my very first all-glass silicone-constructed aquariums. My father and I stood in front of it for a bit, marveling at the fact that it seemed to be holding water; we both "knew" that this was a crazy idea, a fad that would quickly fade into nonexistence. Yeah...not my finest example of future foretelling.

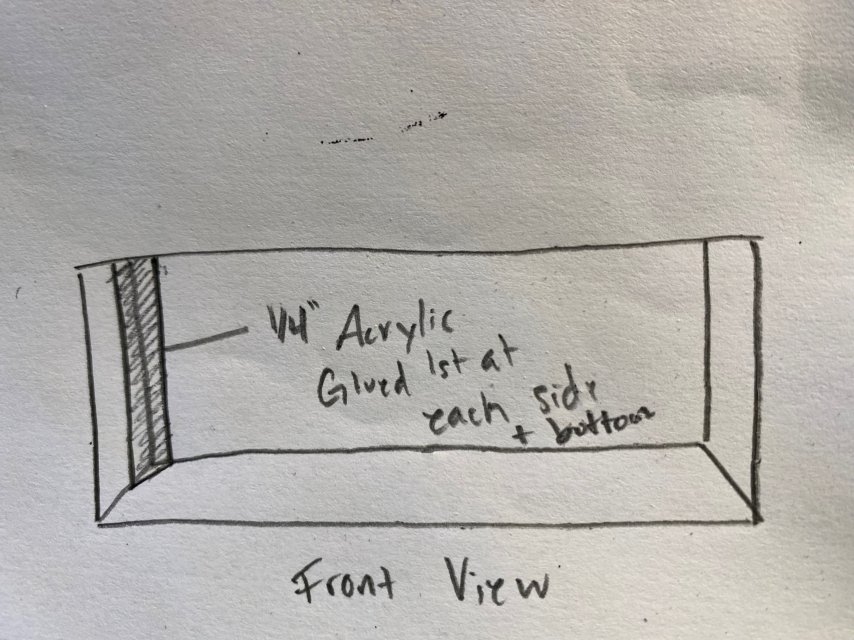

Now I read threads like this one, and I feel more and more that acrylic is just another crazy fad; it's certainly a durable fad, but...hey, come on. There's no way you can build tanks out of this stuff, not while retaining any peace of mind. My blood pressure rises every time I look at this thread.

My blood pressure rises every time I look at this thread.

I must admit: if I were 20 years younger, I'd be building an acrylic tank...just because. But thank goodness I'm too old to start learning new stuff.

Looking forward to following along here some more.

I recall back in about 1970, seeing my very first all-glass silicone-constructed aquariums. My father and I stood in front of it for a bit, marveling at the fact that it seemed to be holding water; we both "knew" that this was a crazy idea, a fad that would quickly fade into nonexistence. Yeah...not my finest example of future foretelling.

Now I read threads like this one, and I feel more and more that acrylic is just another crazy fad; it's certainly a durable fad, but...hey, come on. There's no way you can build tanks out of this stuff, not while retaining any peace of mind.

I must admit: if I were 20 years younger, I'd be building an acrylic tank...just because. But thank goodness I'm too old to start learning new stuff.

Looking forward to following along here some more.