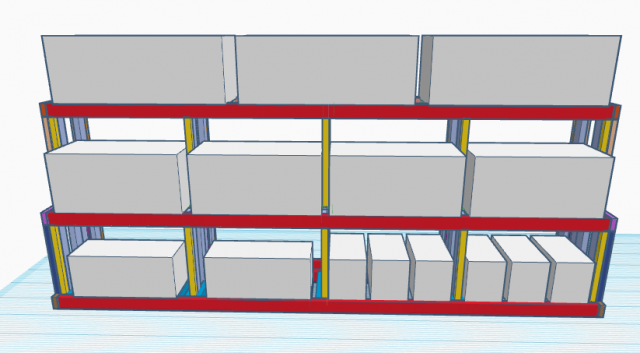

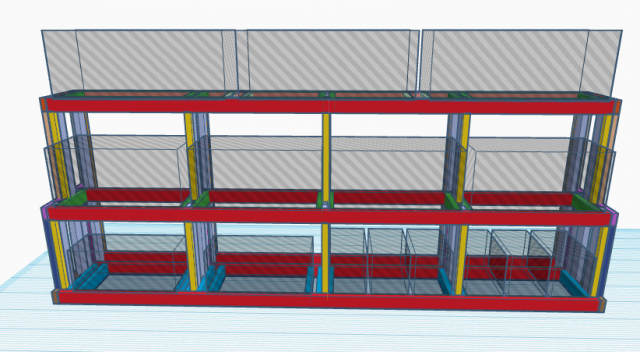

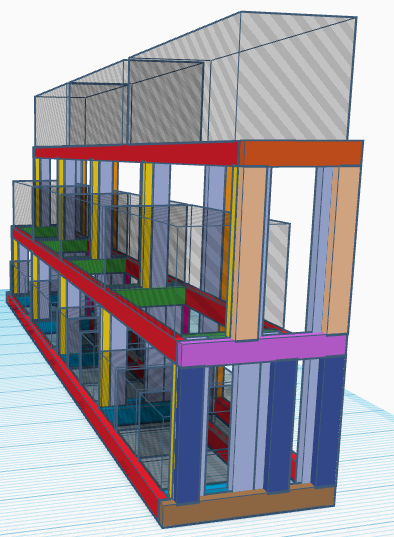

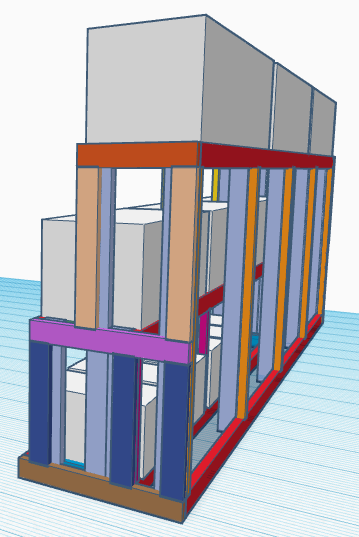

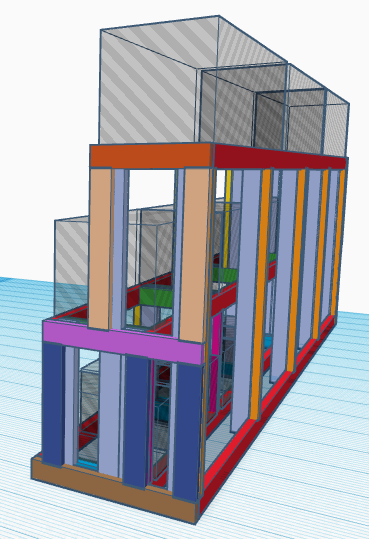

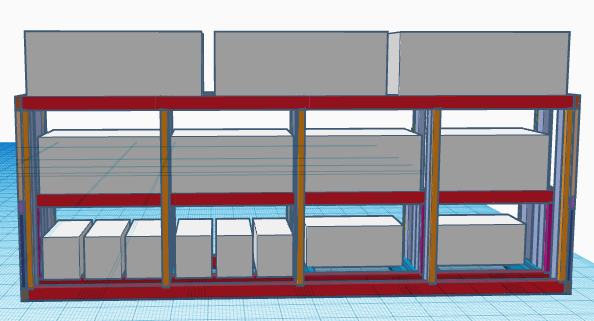

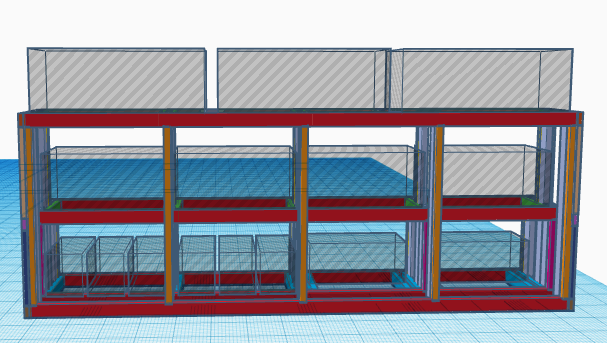

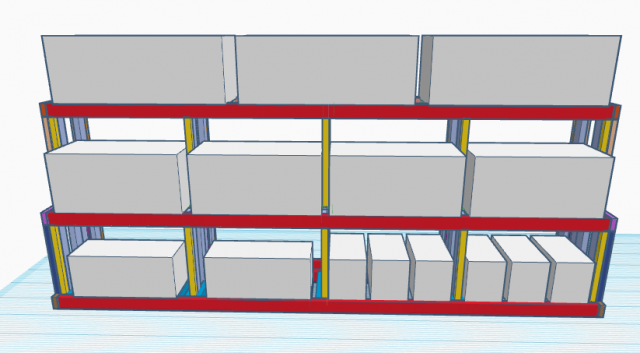

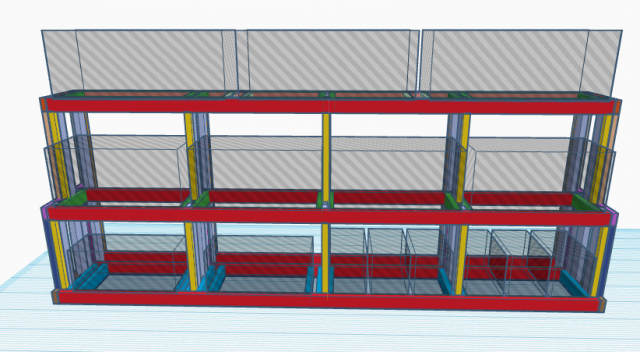

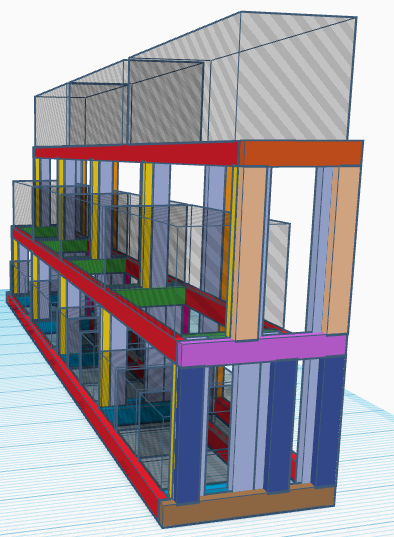

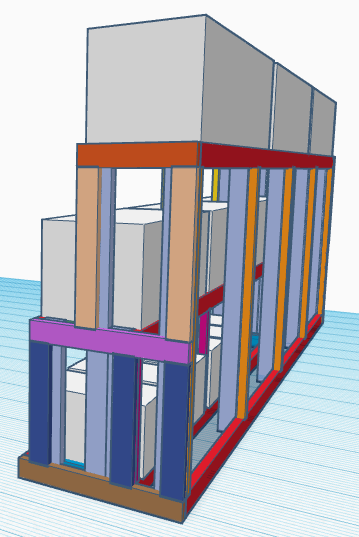

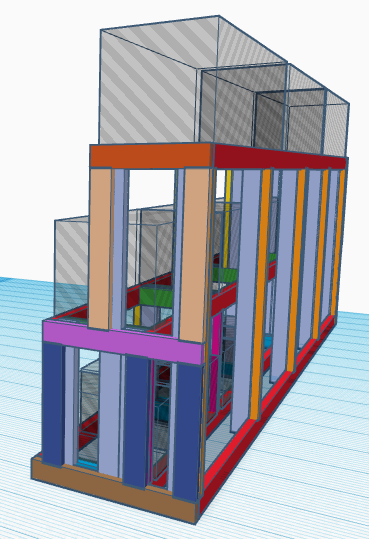

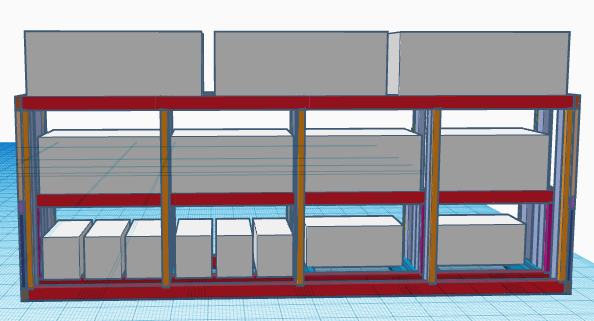

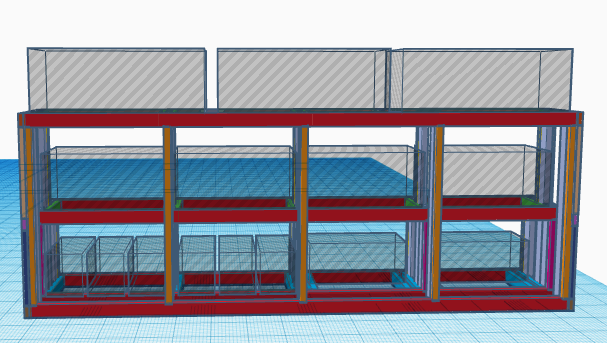

And we're back. As per dad's request, It turns out I will not be drilling into the wall or floor. However, to compensate, I will be making the whole thing a solid 9" wider at the base, and probably using bolts in the top rack. I've added "tanks" to show how everything is sitting. Ignore the middle 60 on the top, I didn't exactly go for precision when putting them in, but all the models are the exact dimensions of each tank.

Need some quick advice on what to do about the back of the thing, does the back look sturdy enough to hold 3 60s some 50" off the ground? I'd think so, with the added vertical supports and presence of bolts. Will it... balance I guess? Construction begins within the next 12 days.

Need some quick advice on what to do about the back of the thing, does the back look sturdy enough to hold 3 60s some 50" off the ground? I'd think so, with the added vertical supports and presence of bolts. Will it... balance I guess? Construction begins within the next 12 days.