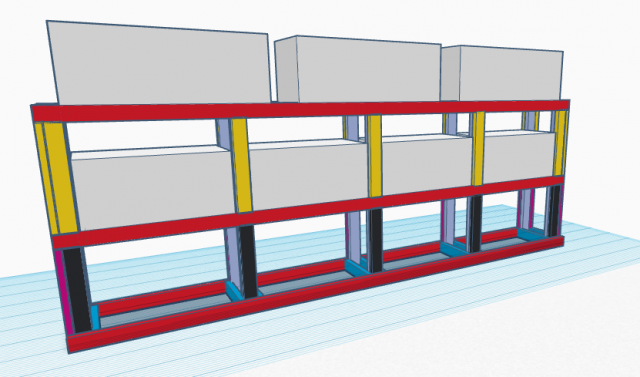

I use some of those industrial metal racks in my basement and garage for storage; they have, like everything else including lumber, skyrocketed in price recently. I like the fact that they are very quick and easy to dismantle for moving or re-configuring, and they go from the box to the fully assembled shelf in literally a few minutes.

But the ones I own and have seen all share a shelf design that consists of a pair of horizontal beams front and rear, with various types of metal screens or grids as the actual shelf surface. For aquarium use I would likely be replacing the grids with sheets of plywood cut to fit...and then of course the plywood would require reinforcement with lengths of 2x4 screwed and glued vertically to the bottom surface to prevent bowing...and then you'd likely want to paint at least the top surfaces of that wood...

I think I'd rather just build exactly what I want out of wood...so that's what I do.

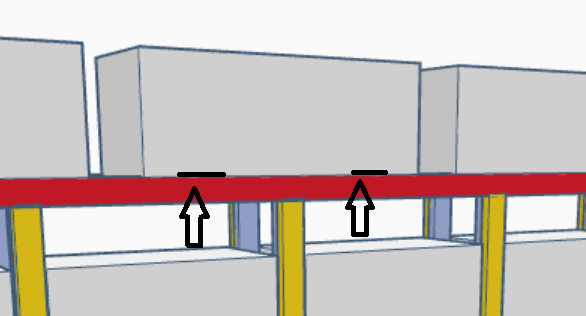

But, yeah, the latest drawing is the first one that hasn't made me do a double-take and say "OMG...he's not gonna build it like

that, is he?"

Now, OP, prepare for the fun job of personally sorting through lumber to find just the right pieces, straight and unwarped. How easy or difficult this is will hinge largely upon your local area; I find good lumber much easier to find in my current home province of Manitoba than I did back in Ontario. Plan out how many pieces you need of the various lengths. No need to buy it all in unwieldy huge lengths when most of your required pieces are short and can by cut from shorter original lengths. Don't just let the lumberyard kid throw the first few pieces into your truck off the top of the pile.

It should go without saying, but I'll say it just in case: Remember that you can't get two pieces 48 inches long from a 96-inch length of lumber. You need to allow for the kerf, the wood lost to the thickness of the blade. Careful planning will minimize the size and number of wasted short cut-off pieces.

And be careful where you store your lumber. If you have a damp humid climate, as I do, then those nice straight pieces you hand-selected will twist up like licorice if you place them on a concrete floor in your garage and leave them there for a couple weeks before using them. I always plan on cutting and assembling my wood within a few days of bringing it home whenever possible, assuming that it is nice and dry to begin with.

The fun is just beginning!