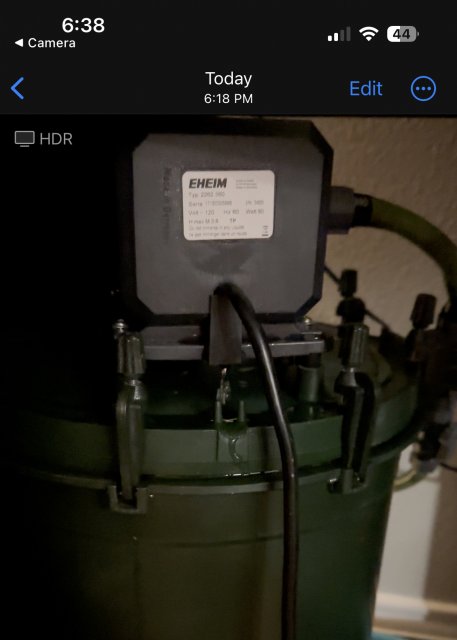

Nice pickup

S

snake_charmer

!

If you are handy at DIY projects and don't like how much space the OEM intake takes up at the tank rim, consider checking out This topic and specifically my posts #23 and #25 for making your own J-tube. But do read the whole topic for additional information.

If you are handy at DIY projects and don't like how much space the OEM intake takes up at the tank rim, consider checking out This topic and specifically my posts #23 and #25 for making your own J-tube. But do read the whole topic for additional information.