On the question of safety. This is roughly what the contractor seem to have done.

On a site such as this there are a number of safety issues relating to

1. Sharp objects such as Nails left from Jigs. Sharp RC Steel Rods sticking from the ground. Removed material from the renovation such as cracked tiles (BTW i accidentally got cut from such a Broken tile just recently from another work site which i was taking a look at - not this one and no the injury was not serious just a puncture wound with some bleeding)

2. Falling Debris - such as Broken Bricks, any loose tools left on the ledges etc. and as memtioned on one of the pictures. Loose Scafolding leading to simple accidents.

3. Electrical Machinery - Power Tools, Electrical Shorts etc ...

Especially when the work area is wet or flooded after the rain. This can be rather nasty and outright dangerous.

There are various sessions which the supervisor briefs them on each day though i missed most of them. The summary points is as follows.

This reno is just a single story extension - so no hard hat (Construction Helmet) was mandated. I asked why not. You would not like the answer.

On Sharp objects - Clean Work Place Mandatory. B4 start and end of day

they spend about 30mins to clean up the place. Nails etc on used jigs are manually removed after the cement have setted.

On Electrical - Gloves and Rubber Boots and the usual precaution applies for power tool usage - hammer drills, rotary cutters and saws.

Hopefully that should keep the workplace and every worker accident free.

Heres a pic of how they put the odds and ends in one place at the work site

Note on Pic 3 the Area for the Dirt and the cleared Work Place

Pic 4 Cleaning up is just with the simple broom, this one in the kitchen area.

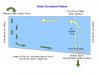

Next coming pics of the completed pond Jigs ready for concreting