That's the best option.The guy who did this told it won't leak and said these things are normal ?and he said if it does then will remove the side panel and clean the silicone and re-fix this side panel (only this panel)

Will that be ok if remove the panel completely and re apply the seams and seal again from inside also

But considering the tank size I think it's 12mm glass. And I firmly believe that removing a 12mm panel stuck with silicone will be a pain in the ass.

Just take a surety from the guy that hell be able to do it cause removing silicone from the sides is easier than removing silicone from the bottom due to the pressure of the weight of glass. Because once you start removing the panel and going through silicone with the blade there's no coming back.

I had my 4*2*2 tank crack ( not leaking) from the bottom, tried removing the panel but in vain. Tank was made from 12mm glass . I got a 48*18" Piece of 12mm glass and stuck it over the bottom panel from the inside.

Just saw that you're from sri Lanka.

You could try out this JUGAAD if you know what I mean.

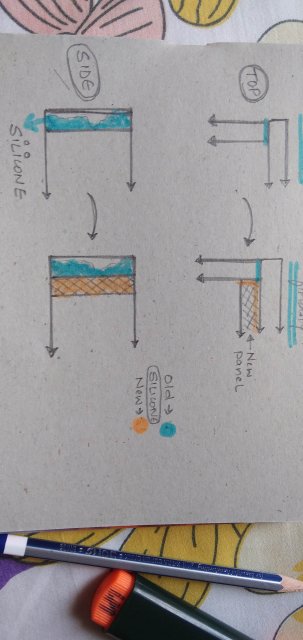

Just stick a 3" Thick panel of thick glass the way I'm holding the copy against glass .

If sticking from outide I'd take a 8mm glass, if from the inside I'd take the exact thickness as the glass used in the construction of the tank.

Sticking from the inside would be more beneficial.

Last edited: