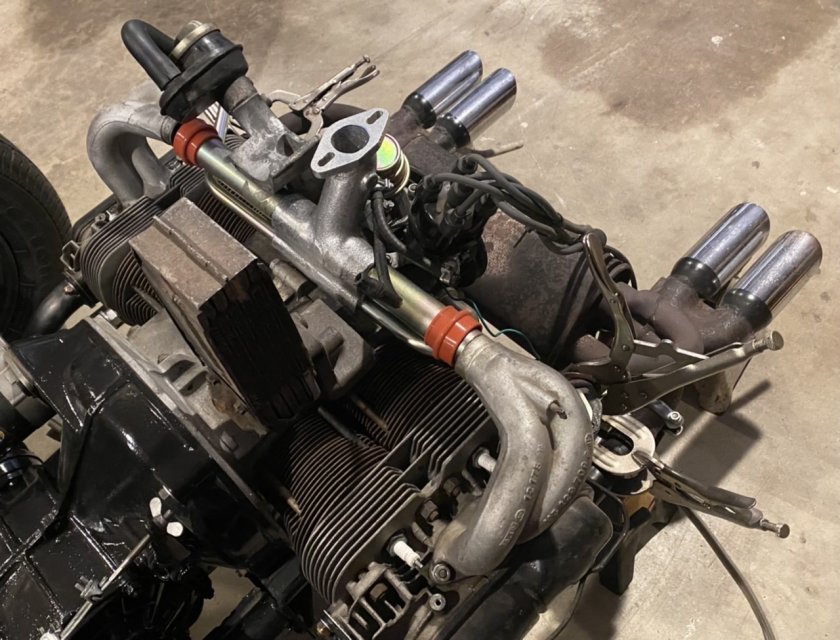

As it turns out I did much more than just straighten my muffler. I wire brushed and repainted the whole thing in barbecue black. I also dressed all the flanges neatly.

I still haven’t solved every fitting issue with the intake manifold but I did two things that improve the fit.

Both of these little flanges for the heat riser tube were cupped. In other words nobody flattened them after they were stamped out on a punch press.

As you can see only one of them would fit at a time. The other one would be pulled way off.

I flattened both of those flanges as well as I could with hammering and I will dress them off on a belt sander until they are nice and flat.

If that wasn’t enough because one of the heat riser tubes was not quite bent to the right angle. I was fortunately able to correct that without kinking the tube.

But that still doesn’t provide 100% alignment. The cast aluminum center section was not machined flat, and so it doesn’t sit correctly on the engine block. It has about 1/16” anticlockwise twist.

Fortunately the design allows for some material to be removed, such that I can file it to get it flat and square with the engine.

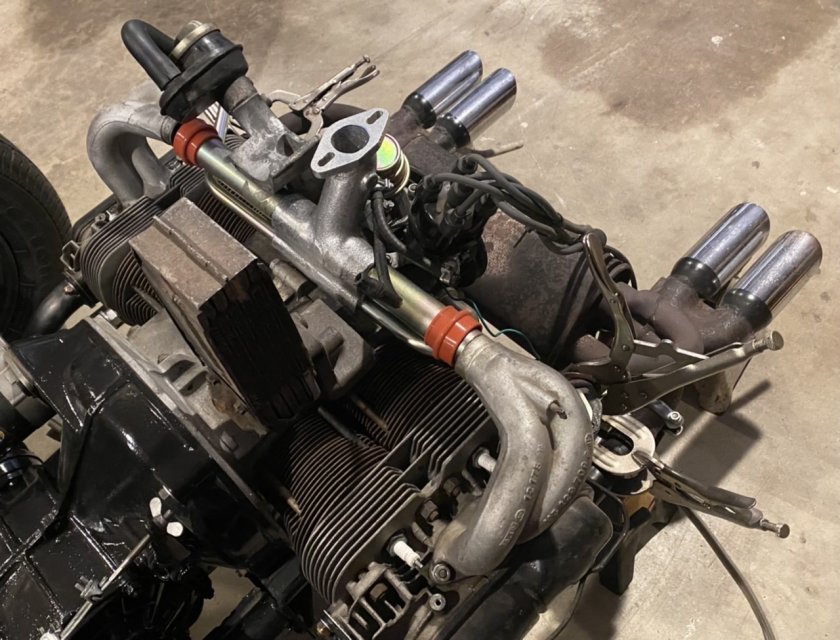

I still haven’t solved every fitting issue with the intake manifold but I did two things that improve the fit.

Both of these little flanges for the heat riser tube were cupped. In other words nobody flattened them after they were stamped out on a punch press.

As you can see only one of them would fit at a time. The other one would be pulled way off.

I flattened both of those flanges as well as I could with hammering and I will dress them off on a belt sander until they are nice and flat.

If that wasn’t enough because one of the heat riser tubes was not quite bent to the right angle. I was fortunately able to correct that without kinking the tube.

But that still doesn’t provide 100% alignment. The cast aluminum center section was not machined flat, and so it doesn’t sit correctly on the engine block. It has about 1/16” anticlockwise twist.

Fortunately the design allows for some material to be removed, such that I can file it to get it flat and square with the engine.