Geez ! Thats a really well thought out plan. The only thing that i can see that may be unnecessary is the siphon bleed valve. Id swap out the ball valve for a gate. Also you may not be able to maintain the siphon unless the drain is submergedBTW there's an obvious mistake in my drawing above.

Who has sharp eyes?

(Clearly not me. I mainly retired early because of eye problems.)

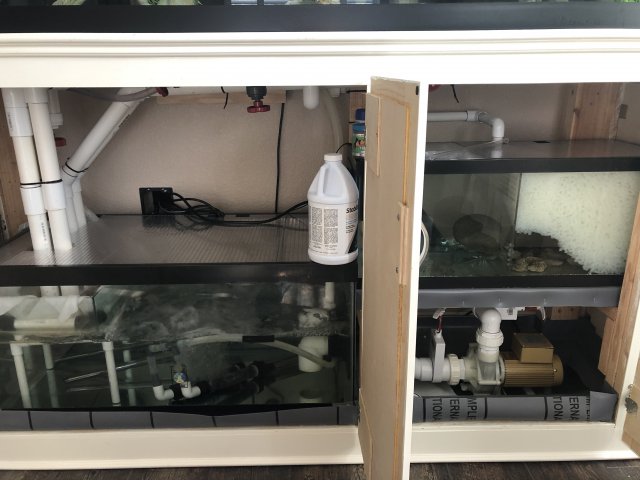

Re-configuring My Sumps with Poret Foam

- Thread starter Ulu

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I looked at your "schematics" and compared it to PYRU's little drawing and chuckled to myself. But that's the engineer in you, attention to detail and such.

You have different types of engineers. I work in industrial reo. We're like the fire fighter division. Things are falling apart and about to blow up you call us. We have lunch I slide you my idea like above on napkin then we go from there lol

First, my drawing mistake was of the typo sort. I labeled the tank twice.

Second, the Poret filters seem to be helping. Not all of them are well-cycled yet though. Time and water tests will tell.

Thanks, I built the system on the fly. The drawing was an "as-built" and came later.

But I studied a lot of DIY sumps before I built it.

The bleed valve on all of my siphons is now eliminated, and I just clip the bleed tube shut with a spring clip. The little valves are unreliable.

The siphon bleed tube is to suck the air out of the siphon so it starts.

I agree about the ball valves. They are a PITA to adjust.

The siphon will always be maintained, regardless of tank level, because both ends always sit in a cup of water. I drain 80% and the siphon starts right back up when I refill. The issue I sometimes have is the tank tops out and the sump starts to run dry. This occurs if leaves or snails etc cover the outflow screen in the tank, or too much bio-crud builds up in the siphon itself.

I went to 1.5" ID drain siphons and larger screens to avoid that issue.

I've worked for a dozen companies and freelance as well. It was all different.

True, some engineering is like MASH. I used to run a field crew out to the Gallo winery on emergencies. I'd fly up and down the west coast to solve construction problems. I've sketched lots of stuff on the side of a tank, on a concrete slab, or right in the dirt. Cut this, weld that, dig here, fill there . . .

But I also checked a lot of drawings. I did things like machine programming, precision pattern making, graphic problem solving, analytic geometry, complex layouts and fixtures, advanced solid modeling, prototype shop supervision . . . Lots of different things, and I used computers to do lots of it.

Way Off Topic: . . . .When congress canceled all the big military orders after Vietnam, thousands of engineers were laid off in California. I lost my engineering job at Manlift & wound up as a union teamster, demonstrating heavy equipment & loading and unloading such. When I made assistant manager of the company after one year, the teamsters sent some gorilla to lean on me, so I'd know who really ran things. It wasn't my only union job, but it was my last. I've been anti-union ever since.

Second, the Poret filters seem to be helping. Not all of them are well-cycled yet though. Time and water tests will tell.

Geez ! Thats a really well thought out plan. The only thing that i can see that may be unnecessary is the siphon bleed valve. Id swap out the ball valve for a gate. Also you may not be able to maintain the siphon unless the drain is submerged

Thanks, I built the system on the fly. The drawing was an "as-built" and came later.

But I studied a lot of DIY sumps before I built it.

The bleed valve on all of my siphons is now eliminated, and I just clip the bleed tube shut with a spring clip. The little valves are unreliable.

The siphon bleed tube is to suck the air out of the siphon so it starts.

I agree about the ball valves. They are a PITA to adjust.

The siphon will always be maintained, regardless of tank level, because both ends always sit in a cup of water. I drain 80% and the siphon starts right back up when I refill. The issue I sometimes have is the tank tops out and the sump starts to run dry. This occurs if leaves or snails etc cover the outflow screen in the tank, or too much bio-crud builds up in the siphon itself.

I went to 1.5" ID drain siphons and larger screens to avoid that issue.

You have different types of engineers. I work in industrial reo. We're like the fire fighter division. Things are falling apart and about to blow up you call us. We have lunch I slide you my idea like above on napkin then we go from there lol

I've worked for a dozen companies and freelance as well. It was all different.

True, some engineering is like MASH. I used to run a field crew out to the Gallo winery on emergencies. I'd fly up and down the west coast to solve construction problems. I've sketched lots of stuff on the side of a tank, on a concrete slab, or right in the dirt. Cut this, weld that, dig here, fill there . . .

But I also checked a lot of drawings. I did things like machine programming, precision pattern making, graphic problem solving, analytic geometry, complex layouts and fixtures, advanced solid modeling, prototype shop supervision . . . Lots of different things, and I used computers to do lots of it.

Way Off Topic: . . . .When congress canceled all the big military orders after Vietnam, thousands of engineers were laid off in California. I lost my engineering job at Manlift & wound up as a union teamster, demonstrating heavy equipment & loading and unloading such. When I made assistant manager of the company after one year, the teamsters sent some gorilla to lean on me, so I'd know who really ran things. It wasn't my only union job, but it was my last. I've been anti-union ever since.

So are you about ready to tap out and go with the simple design yet....I just want to hear the words. You were right

Get a parrot.

"You were right...

You were right...

You were right...

SKWAAAAAAAK!"

I haven't changed anything I am currently running, if that's what you mean.

But I haven't yet really designed the sump for my new "fireplace" system, so it can change.

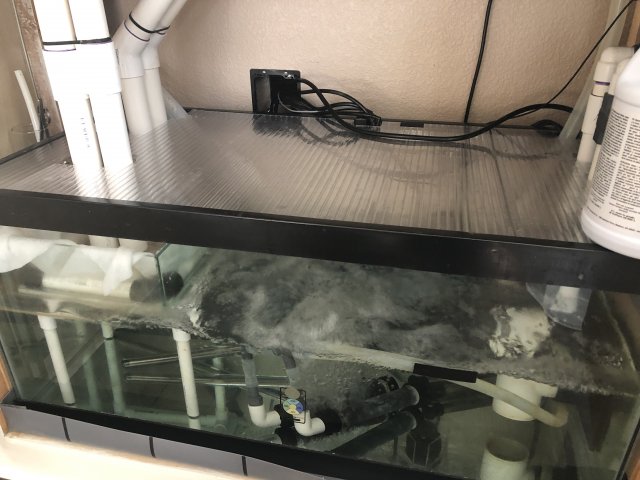

All I have done so far is place the max of extra bio-media in all my sumps so I'll have lots of cycled media to seed the new sump.

First, my drawing mistake was of the typo sort. I labeled the tank twice.

Second, the Poret filters seem to be helping. Not all of them are well-cycled yet though. Time and water tests will tell.

Thanks, I built the system on the fly. The drawing was an "as-built" and came later.

But I studied a lot of DIY sumps before I built it.

The bleed valve on all of my siphons is now eliminated, and I just clip the bleed tube shut with a spring clip. The little valves are unreliable.

The siphon bleed tube is to suck the air out of the siphon so it starts.

I agree about the ball valves. They are a PITA to adjust.

The siphon will always be maintained, regardless of tank level, because both ends always sit in a cup of water. I drain 80% and the siphon starts right back up when I refill. The issue I sometimes have is the tank tops out and the sump starts to run dry. This occurs if leaves or snails etc cover the outflow screen in the tank, or too much bio-crud builds up in the siphon itself.

I went to 1.5" ID drain siphons and larger screens to avoid that issue.

I've worked for a dozen companies and freelance as well. It was all different.

True, some engineering is like MASH. I used to run a field crew out to the Gallo winery on emergencies. I'd fly up and down the west coast to solve construction problems. I've sketched lots of stuff on the side of a tank, on a concrete slab, or right in the dirt. Cut this, weld that, dig here, fill there . . .

But I also checked a lot of drawings. I did things like machine programming, precision pattern making, graphic problem solving, analytic geometry, complex layouts and fixtures, advanced solid modeling, prototype shop supervision . . . Lots of different things, and I used computers to do lots of it.

Way Off Topic: . . . .When congress canceled all the big military orders after Vietnam, thousands of engineers were laid off in California. I lost my engineering job at Manlift & wound up as a union teamster, demonstrating heavy equipment & loading and unloading such. When I made assistant manager of the company after one year, the teamsters sent some gorilla to lean on me, so I'd know who really ran things. It wasn't my only union job, but it was my last. I've been anti-union ever since.

Not fully awake and on my 1st cup of coffee so if im butchering this excuse me.

If you dont keep your sipbons submerged during wc's they dont regain siphon again afterwards ?

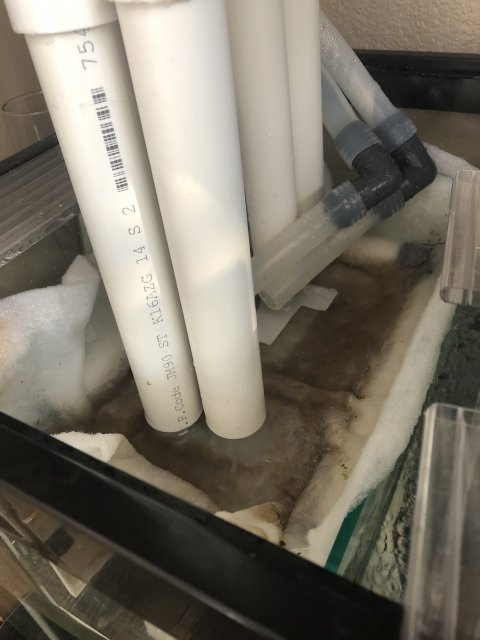

The picture of that siphon above shows it made from two pieces but I actually glued two more pieces of pipe on to extend it another 4 in. It runs in this weir and overflow system, and of course the maximum flow rate is enormous.

It is too much for the Weir in fact and I will have to enlarge that. I attempted to just drill more holes in it, but it is too close to the siphon and will suck bubbles.

I didn't sleep well last night because I kept waiting for my water alarm to go off when this tank overflowed.

It is too much for the Weir in fact and I will have to enlarge that. I attempted to just drill more holes in it, but it is too close to the siphon and will suck bubbles.

I didn't sleep well last night because I kept waiting for my water alarm to go off when this tank overflowed.