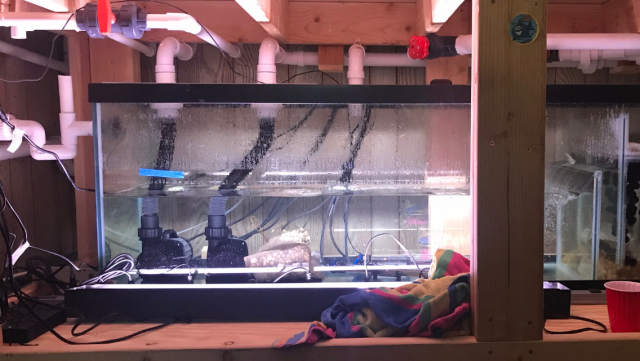

The Jebao 20000 says 5283 gph, I understand that due to plumbing/ head that you may only get half of that, just curious what size tank you have that on? I guess what I am really wondering is are you concerned that the pump could go to 100% flow from whatever you have it set at? possibly from a power outage or something like that. Then have the ability to overflow the tank due to the plumbing not being able to handle the flow?

I think a pump failure like that is unlikely to happen, but flooding can happen--more often the result of one or more of the drains clogging. Its for this reason that every sump setup should include a matching size emergency drain for every drain you are using. These drains are usually set just above the waterline to prevent flooding.