Examples;

www.trademe.co.nz

www.trademe.co.nz

I mean they obviously work, but as someone who's stuck with welded steel for anything over ~120g they just look flimsy AF to me! Very little diagonal bracing and a whole lot of faith in those corner brackets, we do get the occasional small-ish earthquake in my part of the world. I'm looking at setting up something in the region of 200-250g in the coming year, just starting to plan the build.

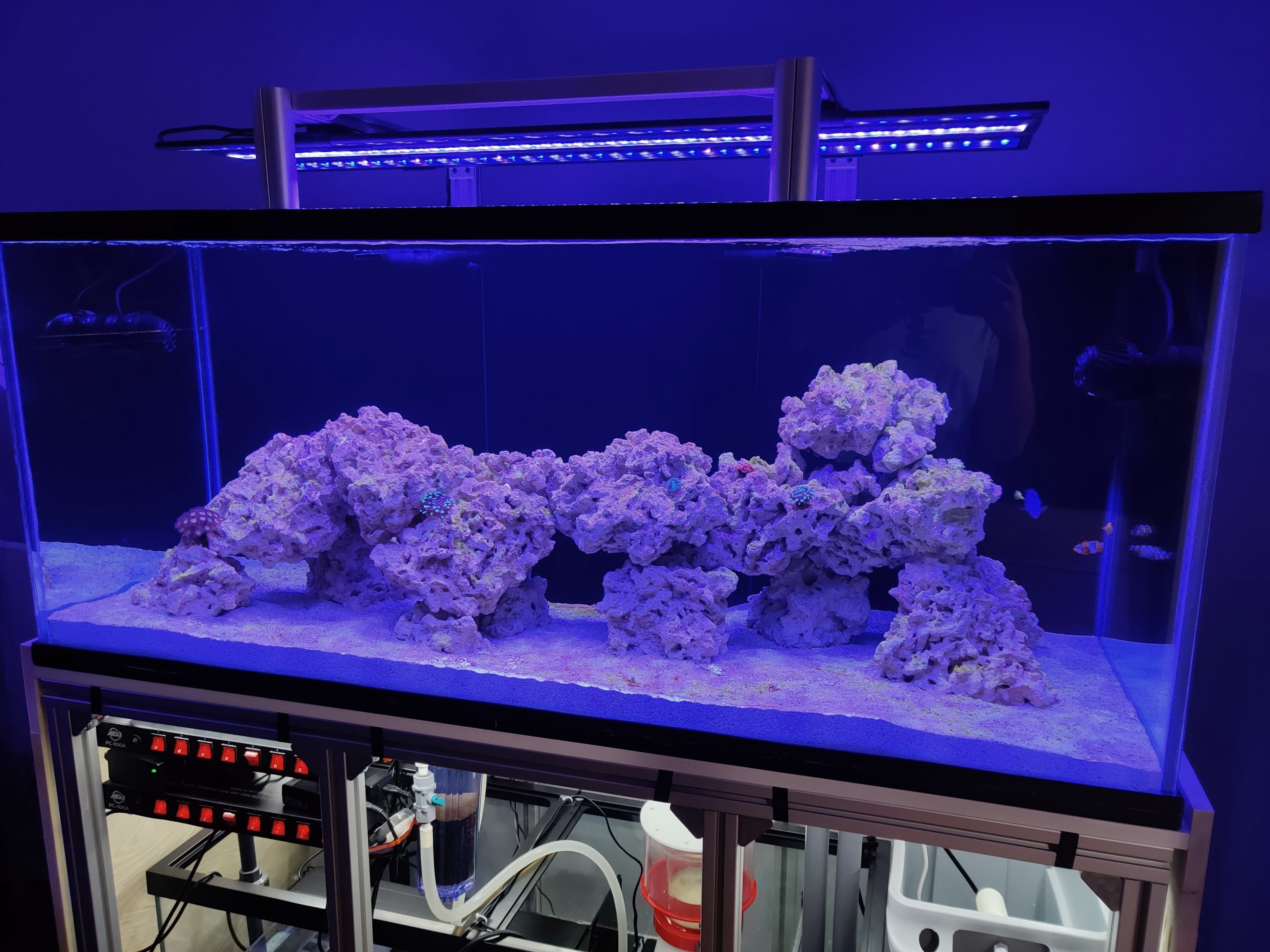

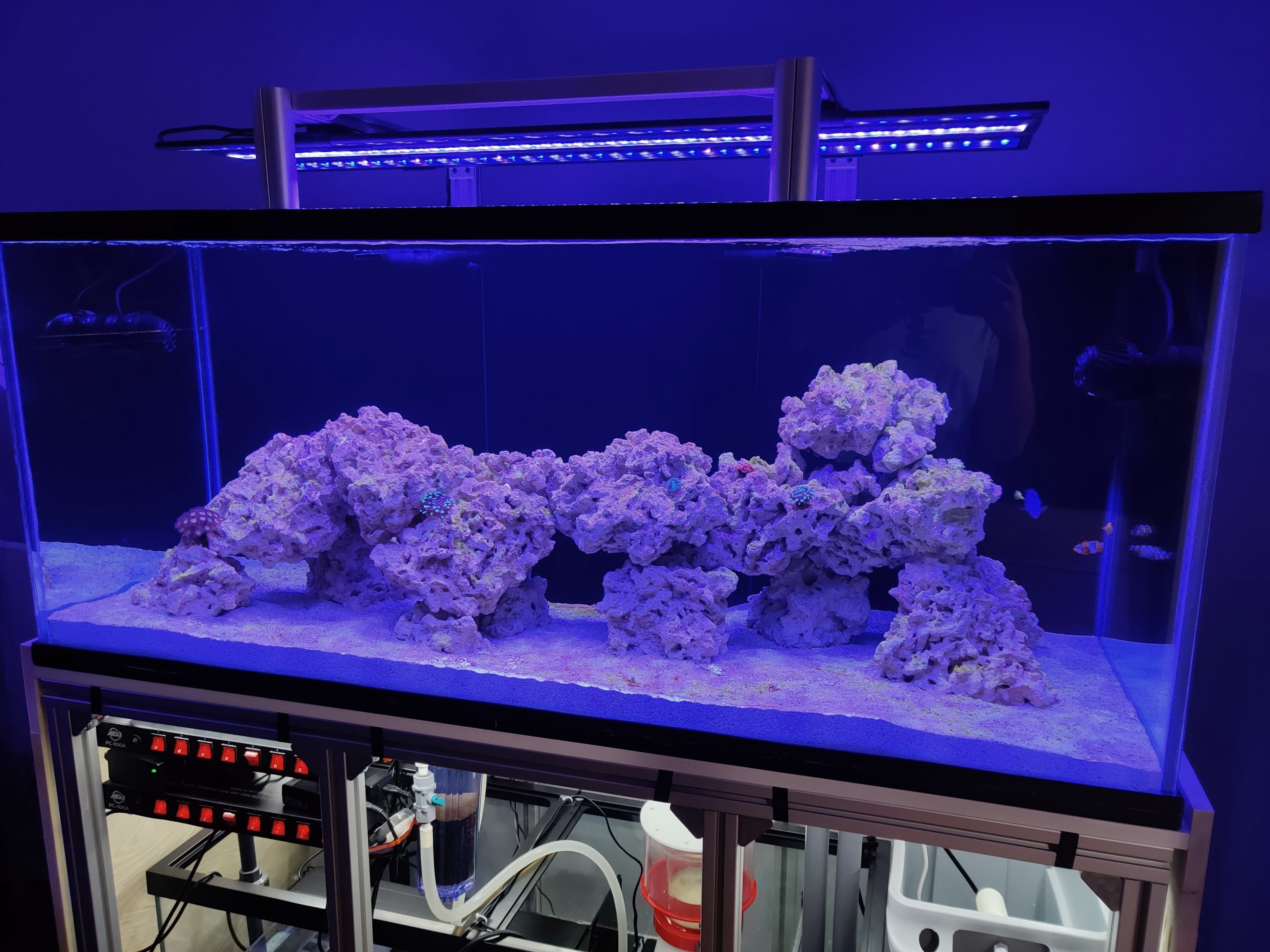

DIY Extruded Aluminum Stand & 150 Tank Build

So I wanted to share my experience building a stand for a new 150 gallon tank I'm working on. I used the same method to build the one for my 80 gallon tank as well! First step was to measure the new tank and decide what I wanted the dimensions of the stand to be. From here it was just a matter of...

indmas.org

Trade Me

I mean they obviously work, but as someone who's stuck with welded steel for anything over ~120g they just look flimsy AF to me! Very little diagonal bracing and a whole lot of faith in those corner brackets, we do get the occasional small-ish earthquake in my part of the world. I'm looking at setting up something in the region of 200-250g in the coming year, just starting to plan the build.