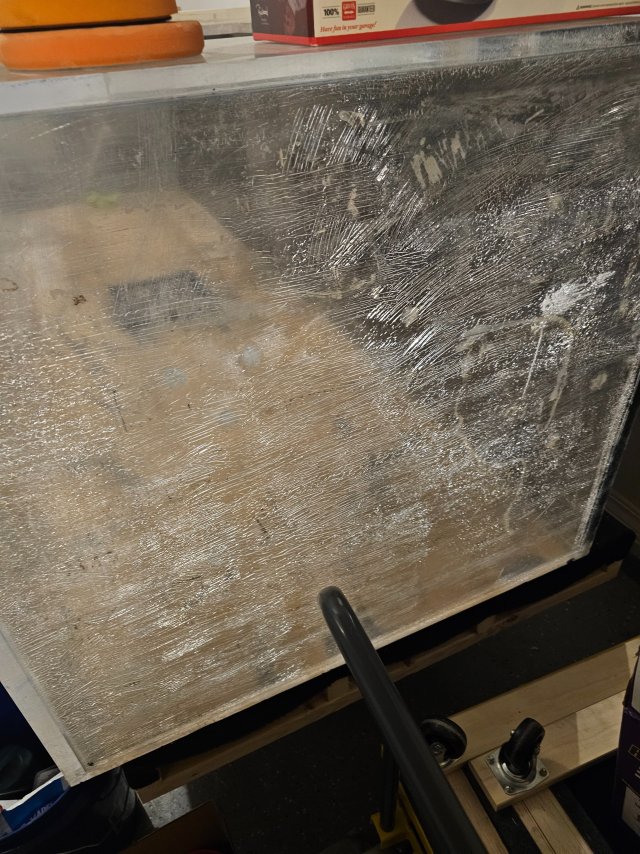

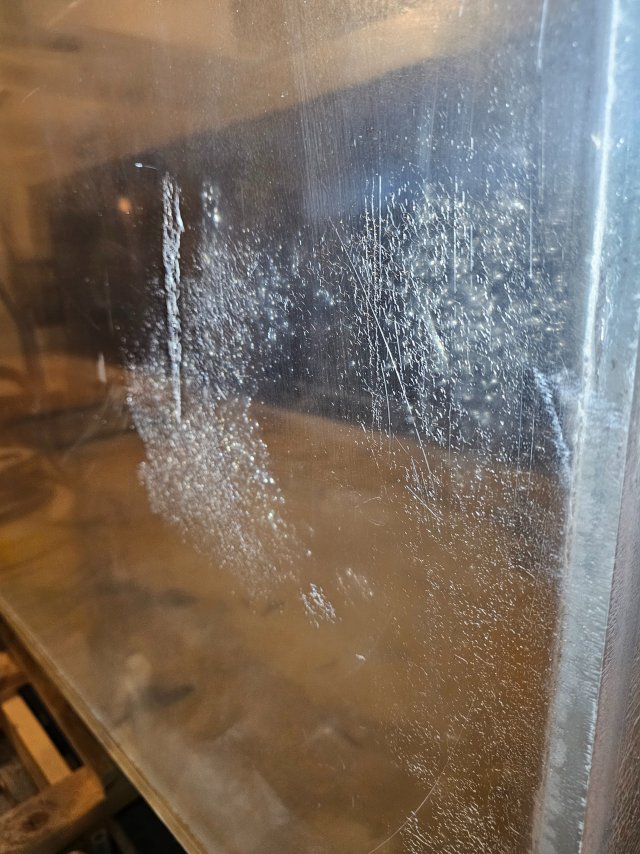

Vertically is the hardest way to work with 40. It is doable tho. A pint should do yeah i think. More is always better tho also. Theres alot of material to cover with 1” rod. Honestly 1/2” or 3/4” rod could be better just for the fact ull probably get more glue behind the rod. Thats more important than using a thicker rod in my opinion. A strip on the outside of the tanks is pretty beneficial also if the seams are really bad. Either way works, inside or out. Both is pretty much making it bullet proof.To clarify, I am just reinforcing the front two seams. Will a pint of 40 be enough?

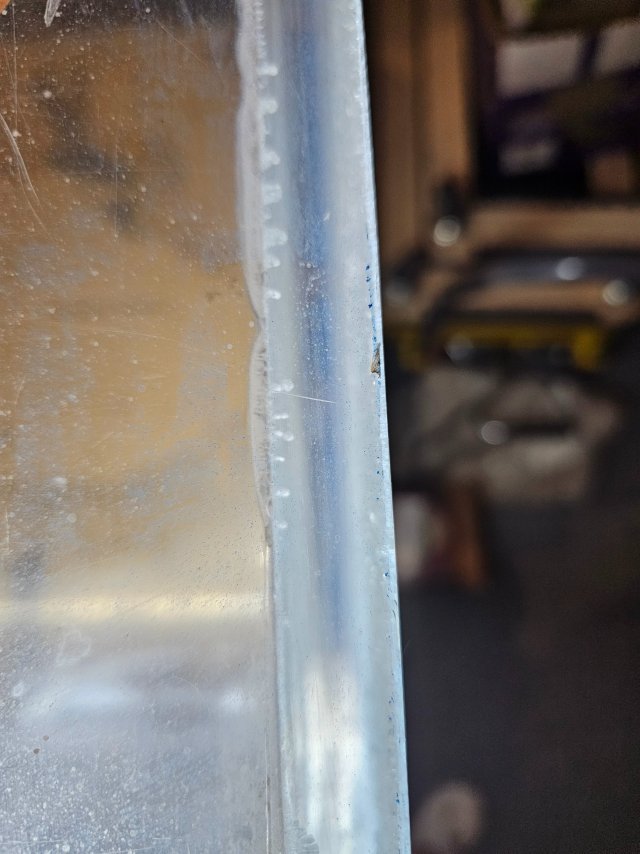

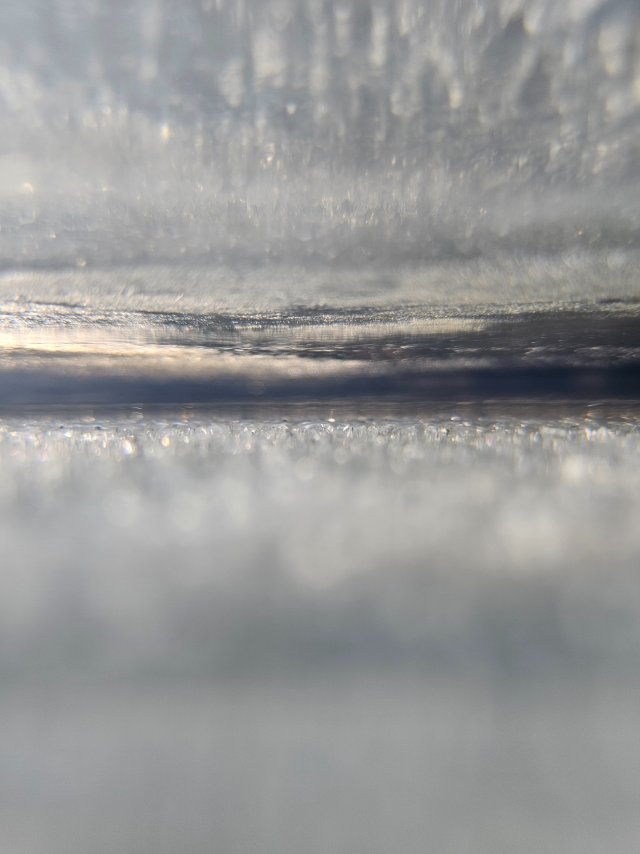

As for application… squeeze/squirt type bottles can work. I use the kind for dying hair or the cheap ketchup/mustard type bottles. You can kinda reuse them but they eventually become disposable. Large 1”+ diameter syringes can work with the tip cut wide. The glue is like cheap cold syrup consistency. Ull be needing alot of glue tho and may waste time there trying to fill the syringe and apply it. Its hard to guesstimate the amt of glue youll need until u do one. Worst case scenario after the rod is glued in you can go back over the 2 ends with more 40 like u would with silicone on a glass tank. You can fill in any air gaps behind the rod as best as possible there also. If ur doing a 1/8” bead/seal most of it will stay put. Some will run down of course before it dries. IME youll have around 15-20 min pot life on the glue. Be carful with syringes/bottles. When the glue goes off its quick and gets pretty hot.

Another tip/trick for working vertically is using tape to cover the area u glued to hold it in. IME packing tape comes off the glue the easiest leaving behind minimal residue. Its hard to peel off the acrylic tho. When they seam together tank panels on sight they actually tape the back seam and simultaneously run tape up the seam bottom to top while injecting glue in. You can get empty silicone tubes and pack them urself with 40 to do things like that.

Lots of ways to work with the glue and solve ur problems. Just have to plan/think it out before you add that hardener. Once thats in its about 15 min to work and thats it. Youll have 1 shot to slap those rods on. They wont come off even if u did a terrible job lol… 40 sticks to itself unlike silicone so worst case scenario u just then seal both sides of rod as mentioned earlier or do an outside strip patch if water breaches behind the rod anywhere just to be safe.

Its a tough one… ive used the squeeze bottles, ive used brushes to wet the tank and the rod before applying and no 1 way is really easier or less messy than the others. Its a pain on large tanks but the best way is to not work vertically and move em. You could glue the bottom/top of the rod in place leaving a 1/8” gap behind then inject from the bottom up covering with tape to hold it in like they do seaming panels. Tough there tho as well shooting to go behind the corner/rod. Only positive of that method is just work ur way up taking ur time. 40 will adhere to itself so u can go 6-12” at a time if u need to not really wasting much glue either.

Most of the rod i put in i used #16 and it failed. How i got into tip/pouring with 40. 40 is most excellent for patch work tho. Used that many times for bulkhead patches, removing overflow boxes and outer patches for seams. Sometimes u just gotta throw as much glue down as u can and slap ur patch on quickly

Hope my long rant helps you decide one of the ways to solve ur problem