Thank you Russell! I appreciate you chiming in. Whew what a relief. Good to move back home but I miss having rays. I still remember buying that oil from you. It was gorgeous.

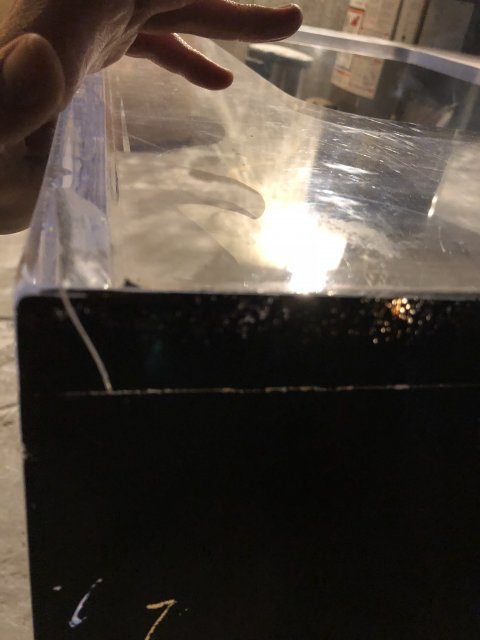

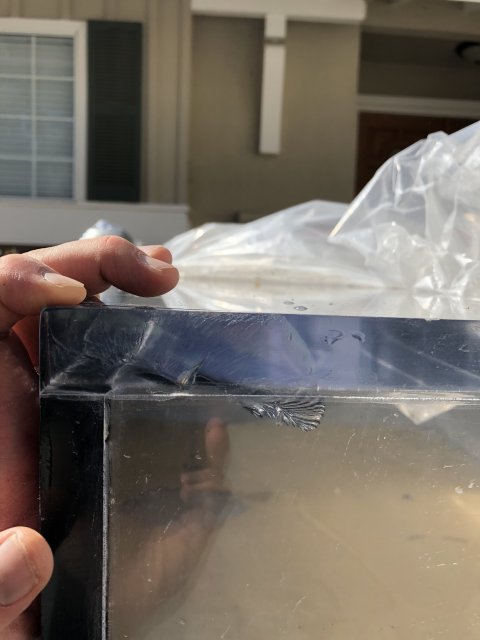

I just bought some Weldon 40. Don’t know if I can get this puppy upside down since four men couldn’t even lift it. I’m thinking of using masking tape and paper to cover up the side underneath where I will be doing repairs and using a clamp to hold the rod in place.

I have some ratchet tie downs so I’ll definitely use those.

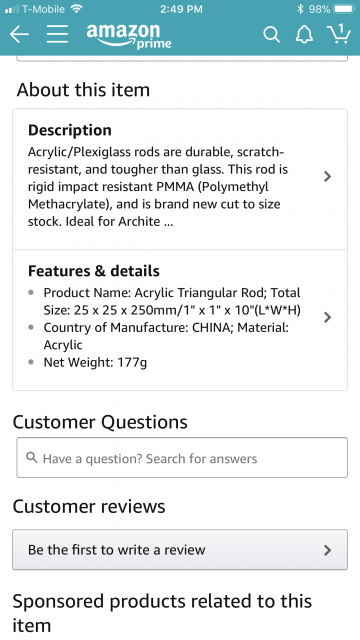

As for the rods, how do you think these will work below? 1”x1”x10” long triangular rods from amazon. Thinking of buying 2 pairs and using two in each corner.

Thanks again

wednesday13

wednesday13

.

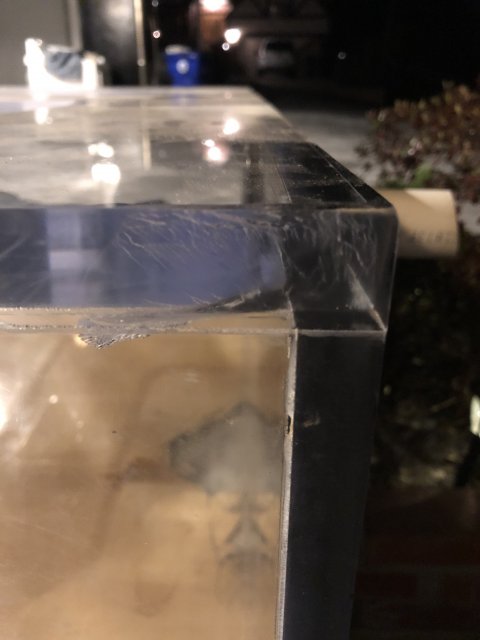

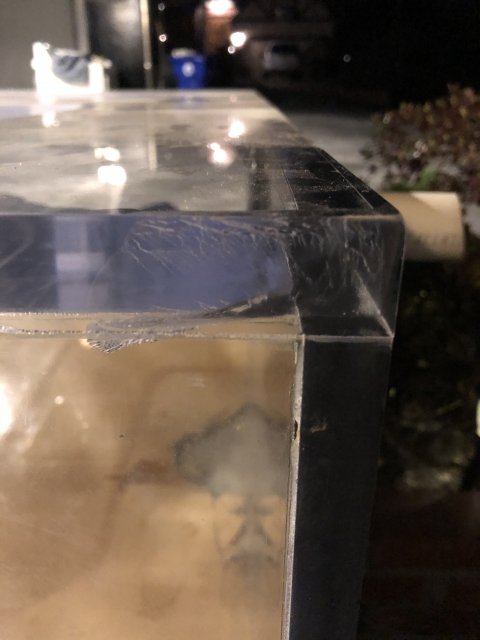

View attachment 1297867 View attachment 1297868

Dragon Hunter

.

Dragon Hunter

.