wednesday13 i propose a truce between team plywood and team styro. Best of both worlds.

In all seriousness though, thanks man. I’ve been doing styro under my tanks for years and could easily tell this is better supported. No distortion

View attachment 1308357

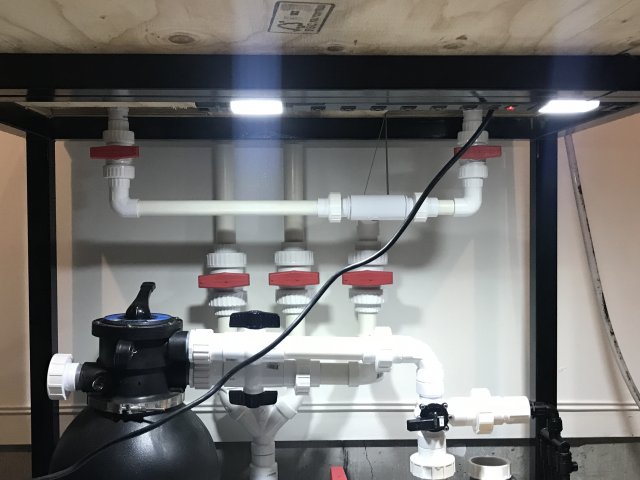

View attachment 1308355

View attachment 1308356

haha... i did notice that foam sandwich in ur pics lol...and i agree, a good solution to an age old problem