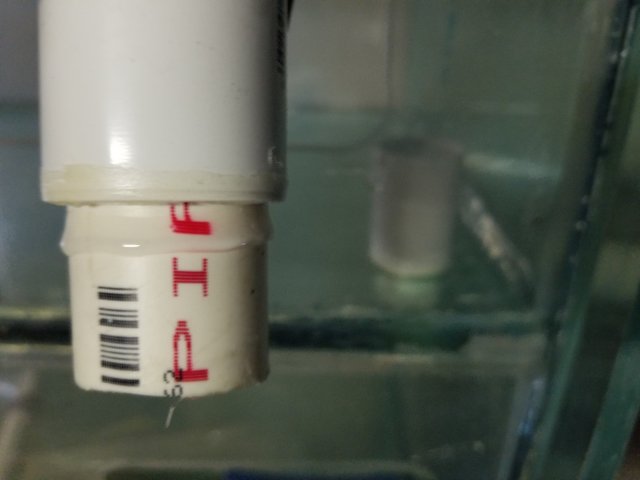

Bead of weld on 40

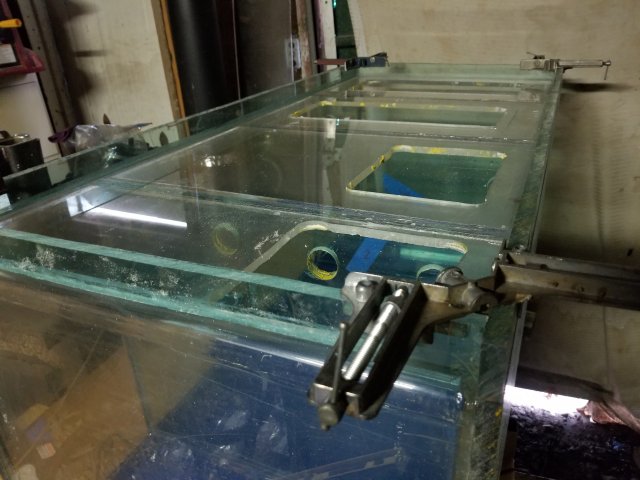

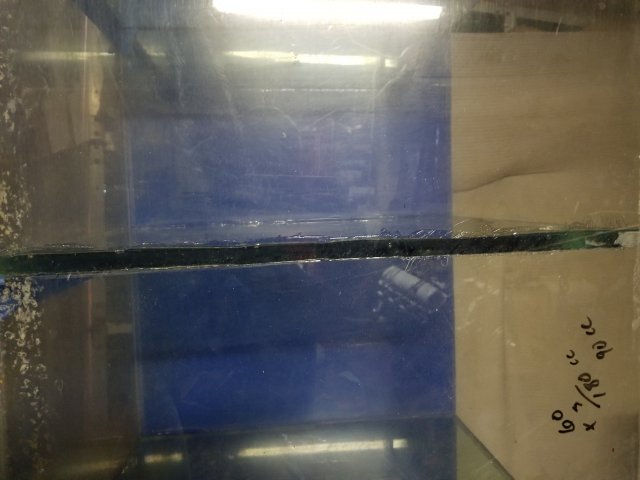

Heavy metal gravitational clamp. Bonded only the bottom edge.

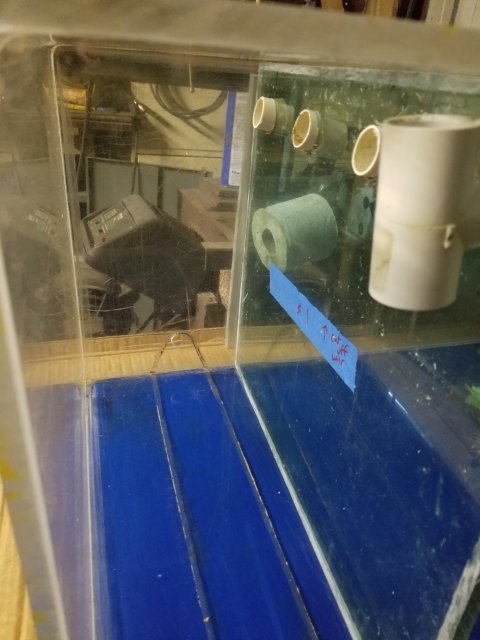

Day 2 the 16 penny nail gap maker. On the opposite side.

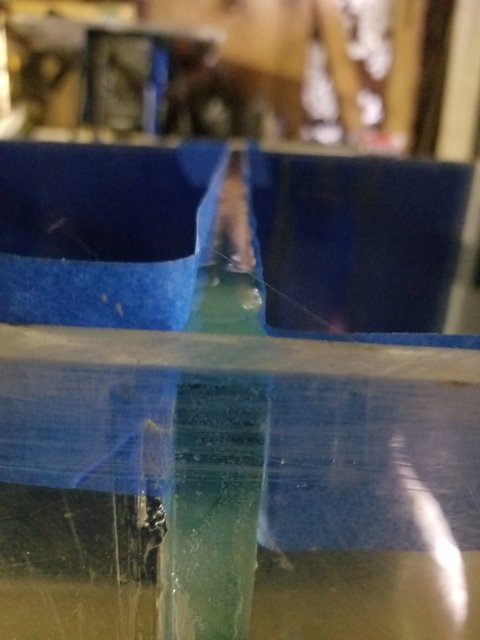

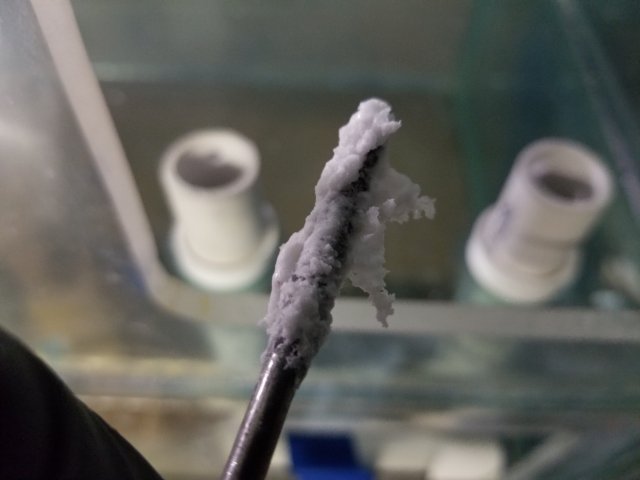

16 penny nail with poor penatration. But it is sealed on one side, about .007 gap.

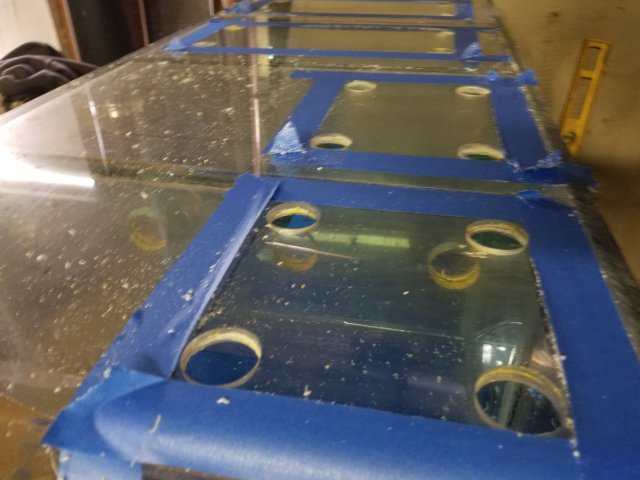

The blue tape is backing.

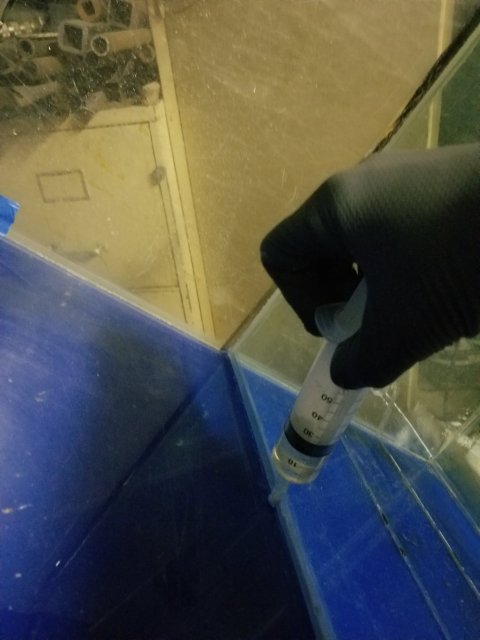

Day 3 pour seams to fill voids. On 16 penny nail side.

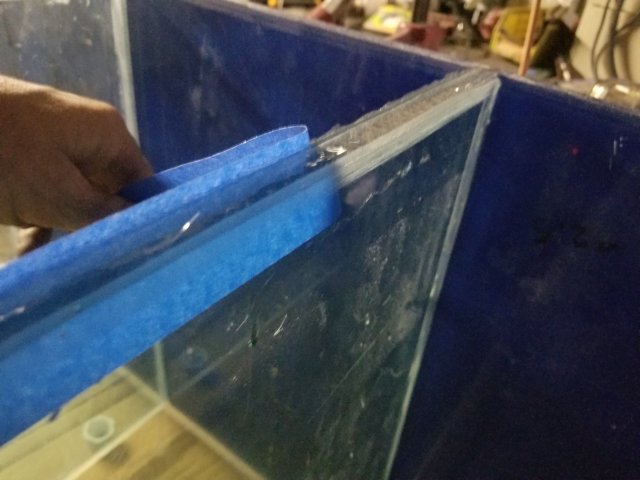

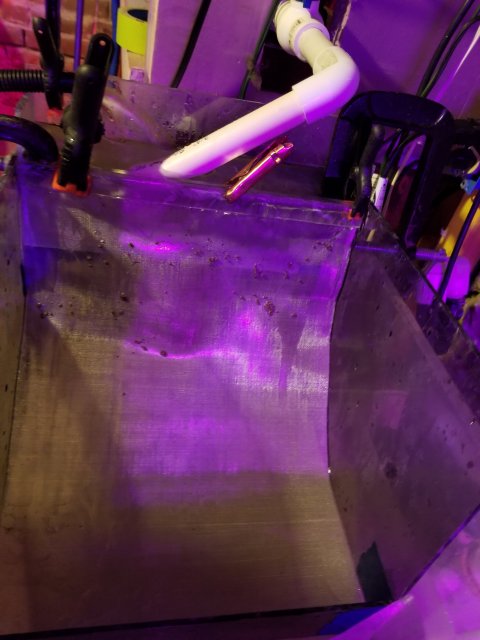

The dark edge is from the sheet of 1/2" polycarbonate bonded to acrylic. The polycarbonate was a freebie, so I am going with it.

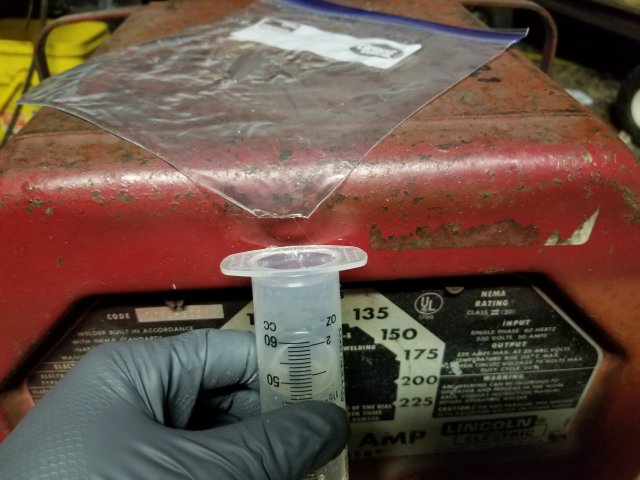

A cathater tip 60mm syringe work great as a caulk gun. As it's too thick for a regular needle type syringe.

Blue painters tape as backing worked great. As it will still pull off after the cement has gelled after about 45 minutes. A razor will cut drips well green.