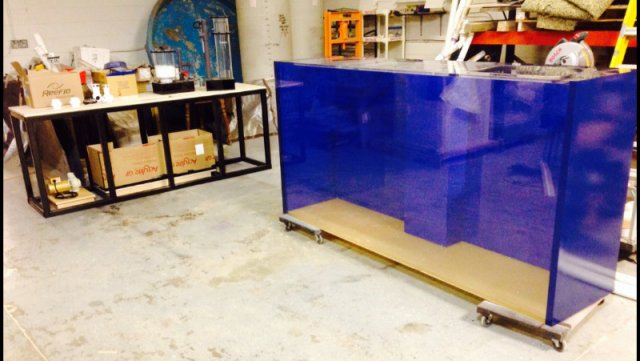

Currently drawing up a plan for my first complete acrylic build which will start up sometime in the next few months. My latest rebuild of a broken acrylic tank into a sump went pretty well and ive been reading up, studying quite a bit to prepare myself but have a couple questions to help me get started.

So far nothing is set in stone but it will be something in the neighborhood of 72"Lx30"Wx48"H. I'll be using 1.25" acrylic for all the sides but im undecided about the top bracing and bottom layout at this time.

-is there any reason why the side panels can't overlap the front and back panels instead of the other way around (the traditional way)? I would rather do this for a few reasons. Mostly because it reduces the number of cuts i have to make drastically on my raw material.

-what are my other options besides acrylic for use on the bottom? Ive heard of people using hdpe, pvc among other things? How would i go about bonding a pvc sheet to acrylic? Would weldon 40 work there as well? How thick of a sheet would i need?

-for the top id like to go as minimal, as open as possible because im most likely making a custom canopy for the tank as well. I was thinking about just using a 1.25" acrylic slab to brace the middle and a thinner strip bracing the ends and corners.

Thanks for reading and for any advice ya mfkers.

So far nothing is set in stone but it will be something in the neighborhood of 72"Lx30"Wx48"H. I'll be using 1.25" acrylic for all the sides but im undecided about the top bracing and bottom layout at this time.

-is there any reason why the side panels can't overlap the front and back panels instead of the other way around (the traditional way)? I would rather do this for a few reasons. Mostly because it reduces the number of cuts i have to make drastically on my raw material.

-what are my other options besides acrylic for use on the bottom? Ive heard of people using hdpe, pvc among other things? How would i go about bonding a pvc sheet to acrylic? Would weldon 40 work there as well? How thick of a sheet would i need?

-for the top id like to go as minimal, as open as possible because im most likely making a custom canopy for the tank as well. I was thinking about just using a 1.25" acrylic slab to brace the middle and a thinner strip bracing the ends and corners.

Thanks for reading and for any advice ya mfkers.