New Build ~ 600 Gallon

- Thread starter JK47

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A friend was over and checking out the progress. He says "uhhh this isn't going to bother your OCD?" Short story is when I tightened the bulkhead fitting it got gummed up on paint and did not tighten all of the way. It was only hand tight. When I cemented everything together, the quarter turn at the end rotated the intake a quarter turn on the reverse side.

Loosening the bulkhead fitting and correcting the intake in turn made the plumbing on the reverse too crooked to continue on as is..

I had to cut this out and redo it. This gave me an opportunity to have the plumbing terminate in a cleaner way from underneath. On a positive note this can be turned this into a win if done properly. That fix is up next.

Loosening the bulkhead fitting and correcting the intake in turn made the plumbing on the reverse too crooked to continue on as is..

I had to cut this out and redo it. This gave me an opportunity to have the plumbing terminate in a cleaner way from underneath. On a positive note this can be turned this into a win if done properly. That fix is up next.

That's a whole lot of work, and that buffing did not look fun. Subbed

Thanks Richard! I promised you the build would get posted back up. Would love to see yours up too

I think the handles pull off. Take the center one off when not in use.

Handles are fine. They are tight but just enough room to fully close off. The crooked pipe on the right is the issue

haha....you're OCD man!

This is true. To a REALLY irritating degree too.. I wish I didn't care lol..

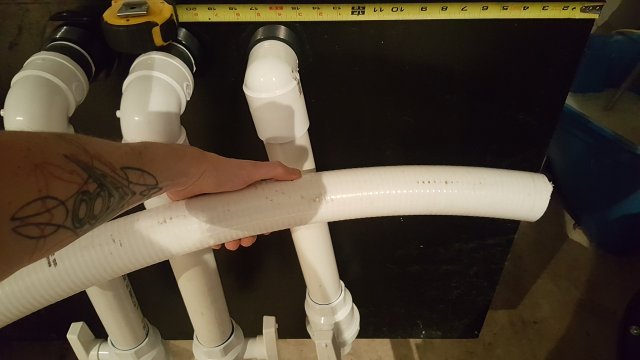

The fix: I decided to move the intake to the right a few inches, use some flex PVC in 2" (for hot tubs/SPA) and used that to correct the angle vertically. I moved it to the right so the intakes to the pumps terminate vertically underneath and will clean up the plumbing when viewed from the front. This changed the design but will look cleaner in the end.

The idea here is to use the natural arch of the flex PVC to right the angle, via an elbow.

Hacking this little bastard off was oddly satisfying..

I used a level to find the horizontal/level arching point where the curve becomes a level plane.

Marked and cut. I cut it exactly 1" longer than the level point knowing the elbow would straighten it out to some degree and that is where I want the pump.

The idea here is to use the natural arch of the flex PVC to right the angle, via an elbow.

Hacking this little bastard off was oddly satisfying..

I used a level to find the horizontal/level arching point where the curve becomes a level plane.

Marked and cut. I cut it exactly 1" longer than the level point knowing the elbow would straighten it out to some degree and that is where I want the pump.

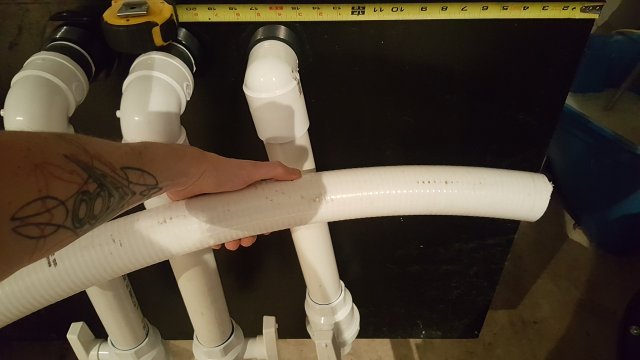

As you can see the angle is now correct and terminates in the correct position vertically.. I used this time to move over the opposing intake as well. Now they terminate the exact distance between the pumps mounted next to one another. I'm really happy I was able to turn a mistake into am improved design.

More oddly satisfying cutting..

You can see the concept I am going with below. I needed another 2" to the right for the second intake to be in alignment with the pump.

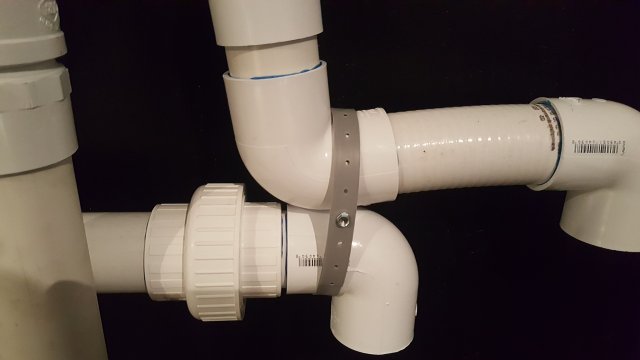

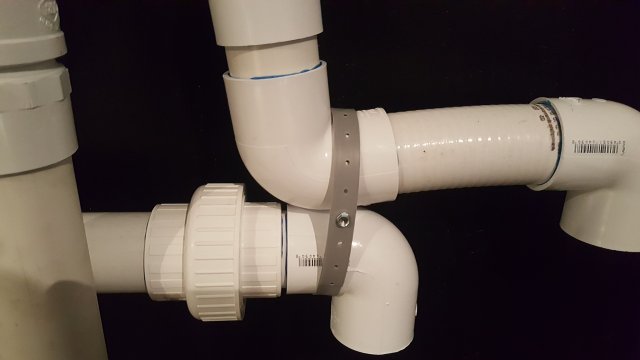

I cut replaced that horizontal pipe with a longer one and moved the union to a more accessible area.

I used a nylon tape and a stainless bolt for hanging pipes to support the weight of a water filled pipe horizontally. I think this elbow is the strongest area just under the bulkhead and will result in no sagging pipes or misalignment.

You'll notice the different length down pipes. Each is cut to length so they terminate at the same height at the bottom.

Measured 6 times before cementing this turd in for the third time..

More oddly satisfying cutting..

You can see the concept I am going with below. I needed another 2" to the right for the second intake to be in alignment with the pump.

I cut replaced that horizontal pipe with a longer one and moved the union to a more accessible area.

I used a nylon tape and a stainless bolt for hanging pipes to support the weight of a water filled pipe horizontally. I think this elbow is the strongest area just under the bulkhead and will result in no sagging pipes or misalignment.

You'll notice the different length down pipes. Each is cut to length so they terminate at the same height at the bottom.

Measured 6 times before cementing this turd in for the third time..