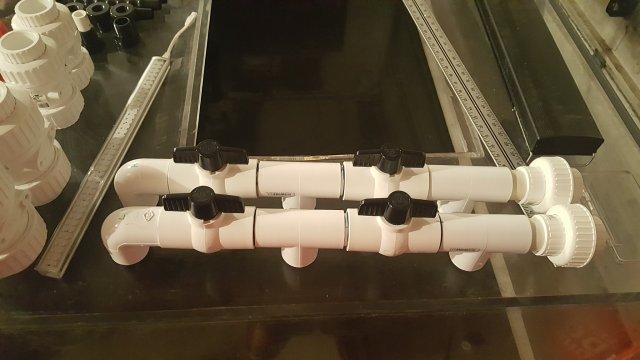

The finished product below. As you can see everything terminates in the proper position and will look much cleaner from the front of the tank. OCD is officially in stand down mode... I'm happy with this.

Not bad, huh? All solvent welded and the down pipes are positioned correctly and evenly. This will be much easier to connect to from under the tank.

If you can envision these two pumps facing the opposite direction, you can see why this design is better for where they terminate. They will also be centered in between to two vertical posts in the stand. Nice and clean. You will also notice the 1/4"-1/2" left between the pumps so they do not touch one another. I don't want any humming or odd vibrations coming from the pumps touching.

Next up: returns from the pumps.

Not bad, huh? All solvent welded and the down pipes are positioned correctly and evenly. This will be much easier to connect to from under the tank.

If you can envision these two pumps facing the opposite direction, you can see why this design is better for where they terminate. They will also be centered in between to two vertical posts in the stand. Nice and clean. You will also notice the 1/4"-1/2" left between the pumps so they do not touch one another. I don't want any humming or odd vibrations coming from the pumps touching.

Next up: returns from the pumps.