Weld-on #40 and #42

- Thread starter wednesday13

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

B

BichirKing

moving my acrylic thread here, since you've introduced me to weldon 40 tip and pour technique.

I've read your list, so before I get started, I wanted to make sure I have the right items:

Items Needed

Weldon 40

Measure Cups

Meet Injector Needle (5ml marking)

Plastic food container

Popsicle sticks

Blue Masking Tape

Does anyone have a link to where to buy Weldon 40? I've found a few sources, want to make sure I'm purchasing the appropriate one.

I've read your list, so before I get started, I wanted to make sure I have the right items:

Items Needed

Weldon 40

Measure Cups

Meet Injector Needle (5ml marking)

Plastic food container

Popsicle sticks

Blue Masking Tape

Does anyone have a link to where to buy Weldon 40? I've found a few sources, want to make sure I'm purchasing the appropriate one.

the only place I know of and the stuff i've used came from

https://www.ebay.com/itm/IPS-Weld-O...h=item25820fbcab:g:p2YAAMXQzH9SHisT:rk:5:pf:0

its mixed in a 100 to 5 or a 20 to 1 ratio. the warmer it is the more easily it flows. be very careful when you pour it as you really cant get it off completely.

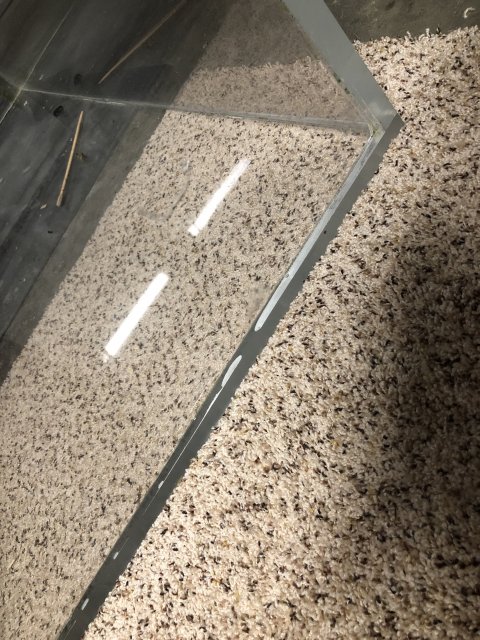

as far as how I got the tank into position to pour the corners heres a pic of doing the ends/sides

I posted earlier on this thread a pic of the stand I made to do the long pours. I will be posting a new thread when the tank is up and running. feel free to ask anything and i'll do my best to answer it.

https://www.ebay.com/itm/IPS-Weld-O...h=item25820fbcab:g:p2YAAMXQzH9SHisT:rk:5:pf:0

its mixed in a 100 to 5 or a 20 to 1 ratio. the warmer it is the more easily it flows. be very careful when you pour it as you really cant get it off completely.

as far as how I got the tank into position to pour the corners heres a pic of doing the ends/sides

I posted earlier on this thread a pic of the stand I made to do the long pours. I will be posting a new thread when the tank is up and running. feel free to ask anything and i'll do my best to answer it.

Ill answer ur second question first lol...in my opinion whats the point of paying extra for #42, a special gun to use the cartridges, and the cartridges when you can just buy #40 and shoot it out of all different kinds of applicators specific to each job. I use larger type syringes, squeeze bottles in a range of sizes and even just pour seams right out of a mixing container. Yes #42 may be neater in the aspect of not making a mess on ur acrylic and for cleanup but as for performance theres no difference with the right tools/applicators than can be found around the house or a dollar store.

Now back to why its not always best to use #40-42 on other types of plastics for lol...will it work? Yes....how well does it work is the real question. it does not give you the same results and strength as when you use it on acrylic. There are different solvents and methods like heat welding used to bond these other types of plastics for a reason. Ill try to find a data sheet from the weldon website for different materials. For example, say acrylic to #40/42 bond is 100% adhesion. #40/42 to a.b.s. or p.v.c. may drop as low as 40-60% adhesion. Thats a huge difference when were dealing with water pressure and making a water tight seal. If you tried to use a.b.s. sheet and #40 to construct a tank it would explode. Heat welding is used for most all plastics other than acrylics/polycarbs because it literally melts the sheets togehter. Cheap plastics like glass tank trim are just that, cheap plastics. Sometimes there not worth fixing. Its very possible the heat created when the weldon #40/42 starts to cure can warp, distort, or even melt the trim.

Just getting the point across the glue is not full strength on other materials. It may work for a certain case, it may not. More for non structural applications. I think u could get away with fixing some tank trim. I also think u could probably pull it back apart very easily lol...

Getting 2 things to stick together is easy, scotch tape will do that lol...physically melting them together permenatly with solvents/epoxies/heat can be harder and there are different ways to permenatly bond different materials. Just like putting regular silicone on acrylic. Yes it will stick, but u can also pull it right back off.

Sent from my SAMSUNG-SGH-I747 using MonsterAquariaNetwork App

Tried to start one of these threads a long time ago and no one seemed to believe me about the quality of this glue and its purpose in the aquarium industry. I am more than glad to know people are now catching on and following my advice and practices of using #40. I know some people are probably tired of hearing about it but I've been getting a lot of p.m.'s about this product and how to use it. #40/#42 is the only glue anyone should be using to repair an acrylic tank, it is 30 times stronger than weld on #4 and 60 times stronger than #16 (this information is provided by the weld-on company themselves not me). It is a two part epoxy that is simply mixed and applied. #42 is #40 being sold in the smallest "kit" they make, it pre mixes for you like when you buy an epoxy from home depot in the plastic tubes. If you have an acrylic tank chances are it was built with #40 in the first place. A lot of people build with #4 or #16 and it is good for small applications like when using 1/4",3/8",1/2" if your good lol.... I've built many acrylic tanks with #4 and #16 for years but still reinforce the inside of them with #40 to prevent any crazing or seam popping down the road. Tanks 15-20yrs old came "stock" with #40 tip and poured on the inside of them and I really don't understand where this practice was lost on tanks being sold today. My opinion is newer tanks are being made cheaper and newer builders just don't know about the product or are making more profit by using cheaper acrylic cements. #40 first and foremost can be used to weld together any thickness of acrylic with crystal clear seams. Its second purpose is using it for inner reinforcement that looks similar to silicone on the inside of a glass tank. #40 can prevent and repair any seam "crazing" or separation. Any used acrylic tank I buy, I take the time to reinforce them with #40 just to never worry about them lasting for my lifetime. I have tanks over 20yrs old that were made this way and there still going stong today. That's enough backstory I guess lol, anyone with questions about the product or how to use it feel free to ask here. Also feel free to post pics of the work/repairs you've done with #40 to help out the rest of our community. Boring read I know, but it will help a lot of us. i'll get some pics together of tanks ive done with it and the "tip and pour" method of reinforcement. Some people may think reinforcing tanks is "overkill" but it sure helps me sleep sound at night and I honestly prefer the look of it on an acrylic tank. #40/#42 can also be used to "butt joint" two pieces of acrylic on end next to eachother to make longer lengths of acrylic. That's how strong it is. #40 is comprised of the same chemical properties of the acrylic itself. It is more or less liquid acrylic. Just the same as what they mix when casting sheets of it.

Hello going to be building a tank using 40 is there anywhere on here with a how to. Like hold the sheet of the base sheet etc

I AM A NOOB HERE AND JUST ACQUIRED A 150G ACRYLIC TANK WITH SOME LEAKS AT THE SEAM......I QUICKLY SCOURED THE INTERNET TO FIND A FIX AND ALL I SAW WAS #4 & #16.....OF COURSE I QUICKLY ORDERED ON AMAZON AND IT SHOULD BE ARRIVING FRIDAY.....NOW I WANT TO DEFINITELY DO THE TIP AND POUR WITH THE 40!!!.......2 YEAR OLD TANK TANK IS 48X24X30.....WILL A GALLON BE ENOUGH?Tried to start one of these threads a long time ago and no one seemed to believe me about the quality of this glue and its purpose in the aquarium industry. I am more than glad to know people are now catching on and following my advice and practices of using #40. I know some people are probably tired of hearing about it but I've been getting a lot of p.m.'s about this product and how to use it. #40/#42 is the only glue anyone should be using to repair an acrylic tank, it is 30 times stronger than weld on #4 and 60 times stronger than #16 (this information is provided by the weld-on company themselves not me). It is a two part epoxy that is simply mixed and applied. #42 is #40 being sold in the smallest "kit" they make, it pre mixes for you like when you buy an epoxy from home depot in the plastic tubes. If you have an acrylic tank chances are it was built with #40 in the first place. A lot of people build with #4 or #16 and it is good for small applications like when using 1/4",3/8",1/2" if your good lol.... I've built many acrylic tanks with #4 and #16 for years but still reinforce the inside of them with #40 to prevent any crazing or seam popping down the road. Tanks 15-20yrs old came "stock" with #40 tip and poured on the inside of them and I really don't understand where this practice was lost on tanks being sold today. My opinion is newer tanks are being made cheaper and newer builders just don't know about the product or are making more profit by using cheaper acrylic cements. #40 first and foremost can be used to weld together any thickness of acrylic with crystal clear seams. Its second purpose is using it for inner reinforcement that looks similar to silicone on the inside of a glass tank. #40 can prevent and repair any seam "crazing" or separation. Any used acrylic tank I buy, I take the time to reinforce them with #40 just to never worry about them lasting for my lifetime. I have tanks over 20yrs old that were made this way and there still going stong today. That's enough backstory I guess lol, anyone with questions about the product or how to use it feel free to ask here. Also feel free to post pics of the work/repairs you've done with #40 to help out the rest of our community. Boring read I know, but it will help a lot of us. i'll get some pics together of tanks ive done with it and the "tip and pour" method of reinforcement. Some people may think reinforcing tanks is "overkill" but it sure helps me sleep sound at night and I honestly prefer the look of it on an acrylic tank. #40/#42 can also be used to "butt joint" two pieces of acrylic on end next to eachother to make longer lengths of acrylic. That's how strong it is. #40 is comprised of the same chemical properties of the acrylic itself. It is more or less liquid acrylic. Just the same as what they mix when casting sheets of it.

I AM A NOOB HERE AND JUST ACQUIRED A 150G ACRYLIC TANK WITH SOME LEAKS AT THE SEAM......I QUICKLY SCOURED THE INTERNET TO FIND A FIX AND ALL I SAW WAS #4 & #16.....OF COURSE I QUICKLY ORDERED ON AMAZON AND IT SHOULD BE ARRIVING FRIDAY.....NOW I WANT TO DEFINITELY DO THE TIP AND POUR WITH THE 40!!!.......2 YEAR OLD TANK TANK IS 48X24X30.....WILL A GALLON BE ENOUGH?

you shouldnt need that much... 1/2 gal will b more than plenty for those dimensions. it does have a shelf life when opened so its honestly a bit better to order by the pint that way if u dont use it all it wont go bad.

Perfect. I guess i could order thru Amazon. I’m happy I found your thread. I was ready to give up my search in fear of this thing Failing in my house. And just like u said people saying to trash the tanks that leak at the seam. This weekend I’m gonna give it a thorough cleaning let it dry then hit it from the outside with #4 and order the 40 for the tip and pour. Here’s what I’m working with.you shouldnt need that much... 1/2 gal will b more than plenty for those dimensions. it does have a shelf life when opened so its honestly a bit better to order by the pint that way if u dont use it all it wont go bad.

DID YOU POUR ALL 8 EDGES?I used a pint and a half for a 8x2x2 tank.

I did the bottom 4 and the 4 sides I didn't do the top. I filled the corners about a 1/4" deep. the good thing is you can add more to it since this doesn't do a "cold weld". so if you think you need more you can always do another layer.