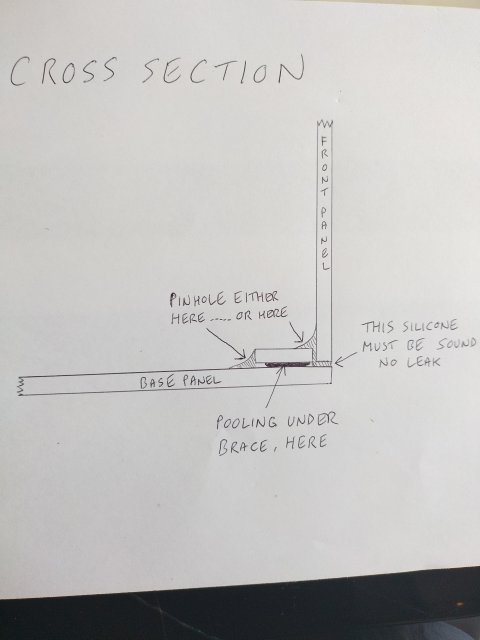

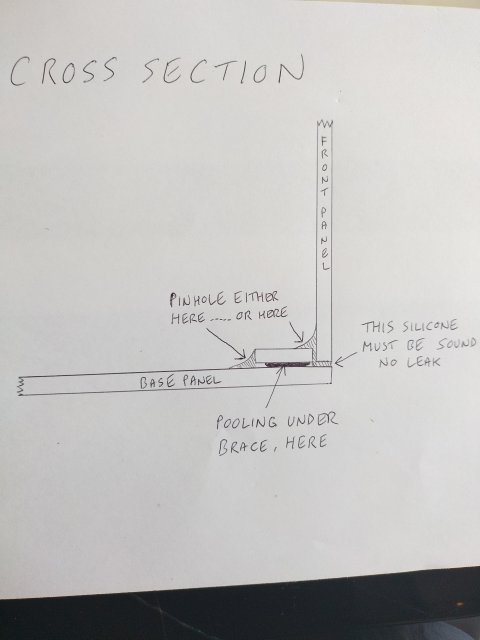

This is scary. The bottom strip of bracing running the full length of my 6x2x2 has developed a "puddle" of water under it, and it is slowly creeping, getting worse. There must be a pinhole sized hole developed in the silicone somewhere. It's difficult to explain but the picture below will give you an idea what's happening. You can clearly see the dark shadow. Also, my diagram shows you where the pinhole is more likely to be.

There's no external leak, not as much as a drip....yet! So I'm guessing that the silicone holding the actual outer panes together is sound. I don't know what the other side is like because I have decor/gravel covering up about 90% of that bracing strip.

The tank water may very well "flood" the whole strip eventually, and still be fine as long as the main silicone is ok. But then again, this could be the beginning of the end of this tank, which is only 6 years old. What do you reckon?

There's no external leak, not as much as a drip....yet! So I'm guessing that the silicone holding the actual outer panes together is sound. I don't know what the other side is like because I have decor/gravel covering up about 90% of that bracing strip.

The tank water may very well "flood" the whole strip eventually, and still be fine as long as the main silicone is ok. But then again, this could be the beginning of the end of this tank, which is only 6 years old. What do you reckon?