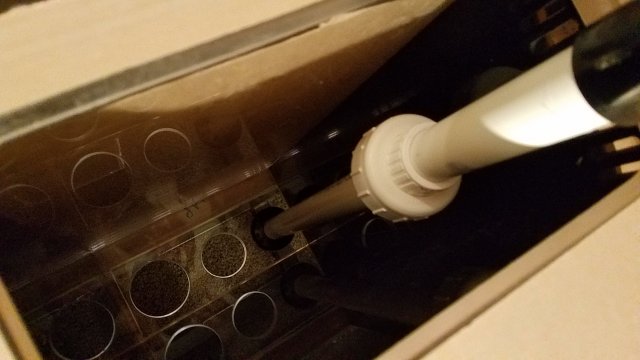

Got the tank side of the returns mocked up. Already happy that i had chris move the bulkhead towads the middle of the tank.

Both nozzles at an even length from the tee.

View attachment 1232510 View attachment 1232511 View attachment 1232512

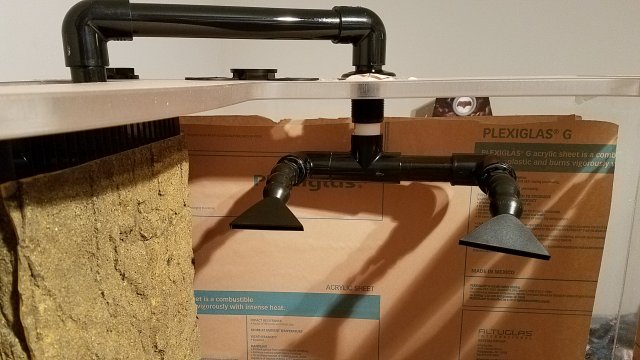

I like this better just not sure how far i want the nizzle furthest from the overflow to extend from the tee.

This is witha 2 inch length of pipe (not two inches from the tee)

View attachment 1232513 View attachment 1232514

3inch length of pipe

View attachment 1232515

4inch length

View attachment 1232516

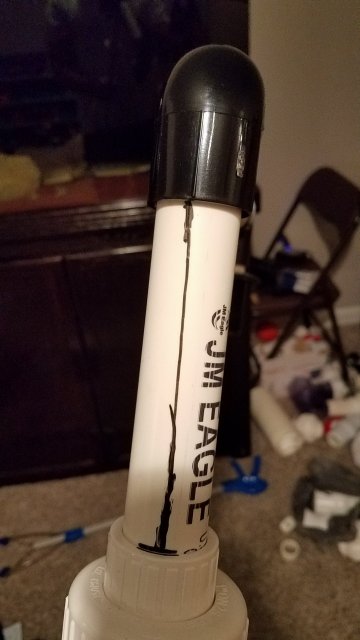

White pvc with be painted. Not sure the length of the loclines but i can always just unscrew them after its up and running to add/remove.

Another option is to extend both loclines rather than having the 90. This way no need for the pvc to extend.