Tasks remaining on the tank itself (It should be wet this weekend):

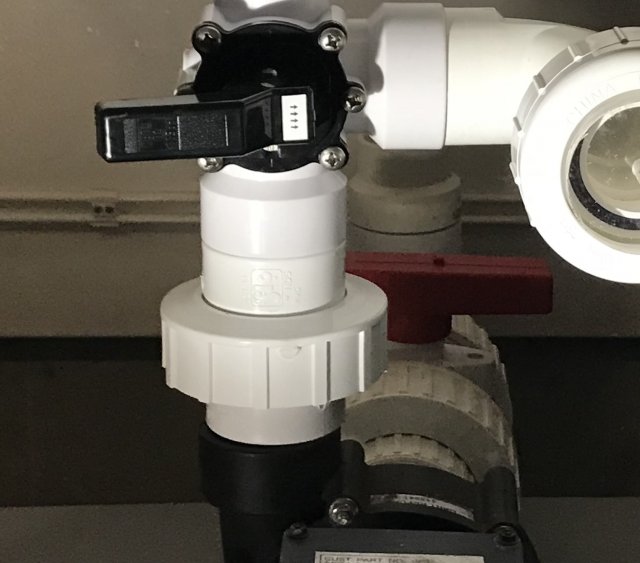

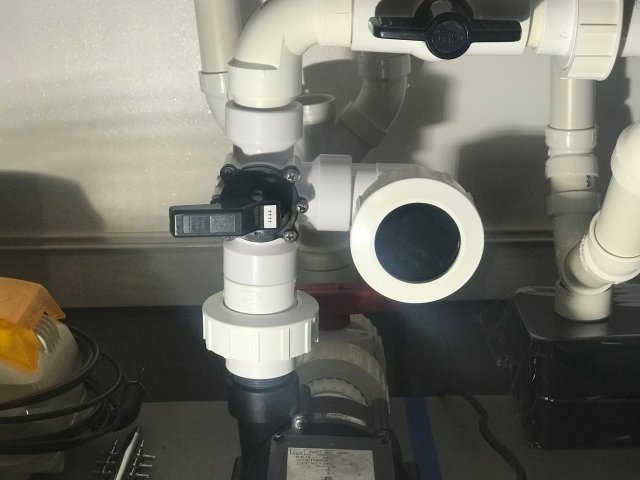

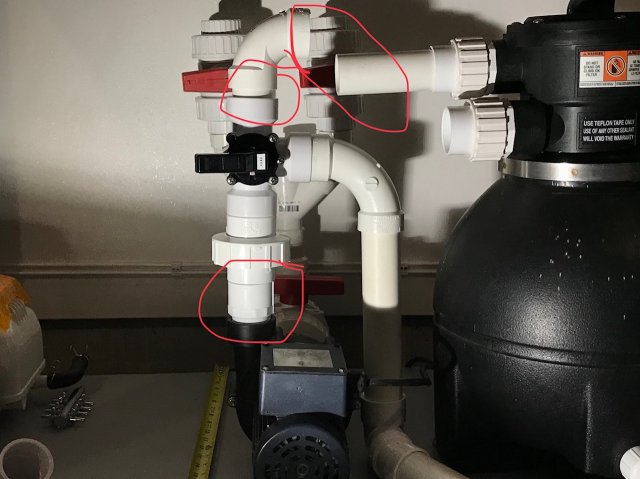

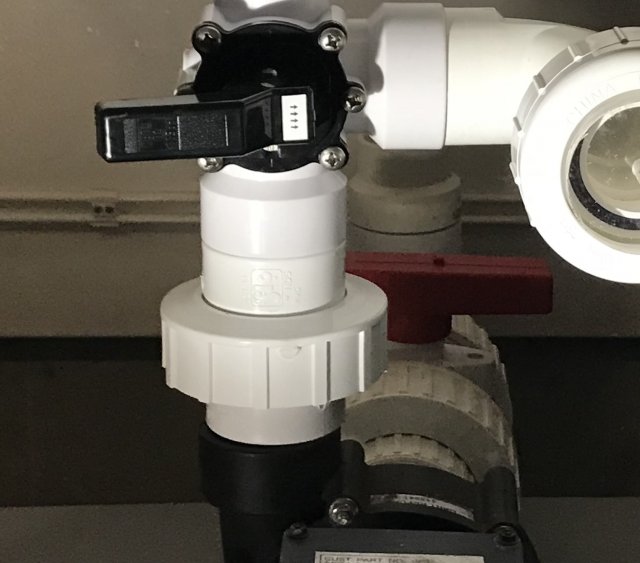

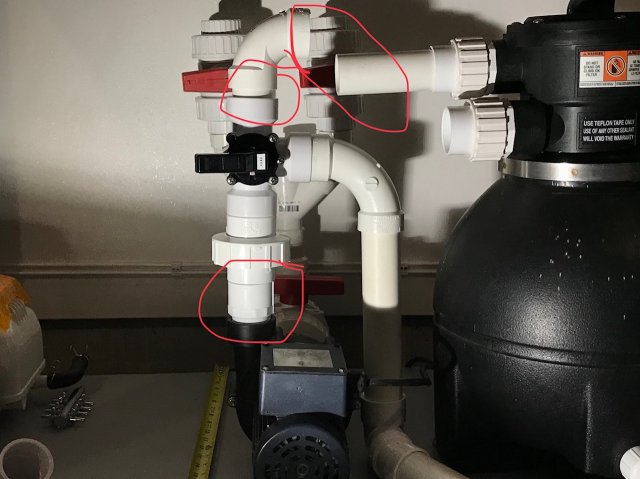

The Ultima 1000 is low in heigh and this line has to fit a union, diverter valve and ball valve in a tight space. As you can see it's about an 1.5" too high and no ball valve yet.

Swapping out the unions for Ace Hardware brand (middle) is 1/4" shorter in height than Home Depot brand (right) plus the union style matches the union ball valves (left) better. Still 1.25" to go though.

I bought a thread x thread union and a schedule 80 threaded nipple for the bottom and kept the slip side of the union for the top, eliminating two fittings or any combo thereof. Removing the thread x slip adapter on either side of the union buys us the 1.25" in height needed and looks like a normal union.

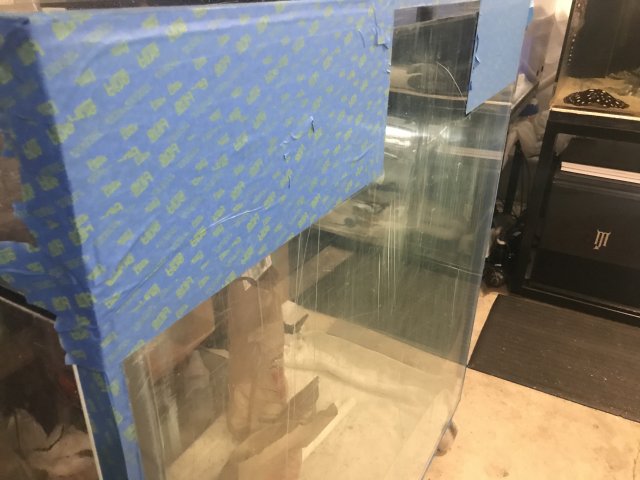

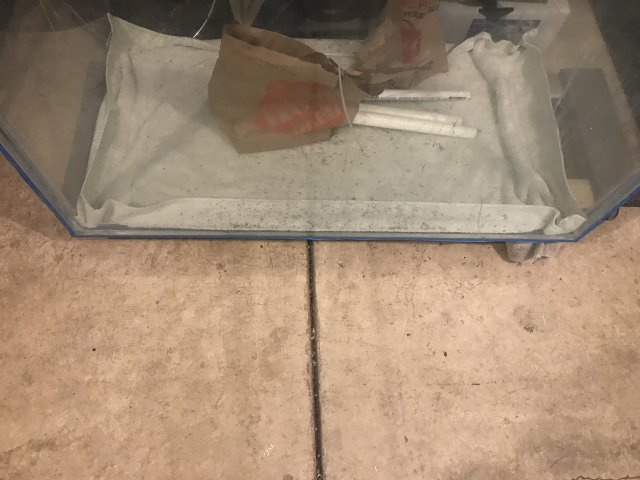

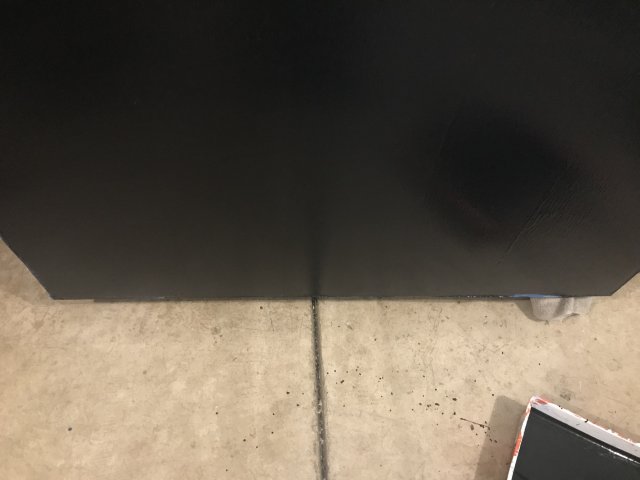

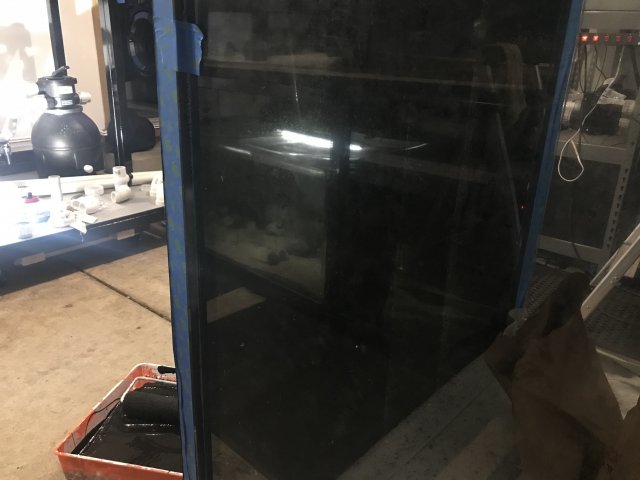

Before & after

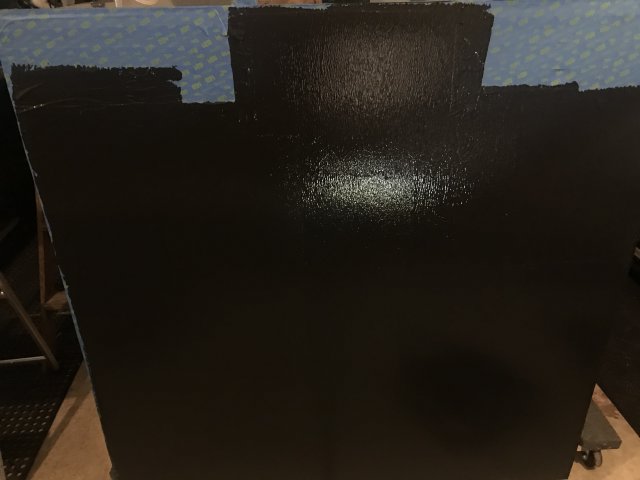

- Paint bottom (tonight)

- Buff interior panels (Tuesday)

- Plumb returns in overflow (Wednesday)

- Place on stand (Thursday)

- Level stand (Friday)

- Fill (Saturday)

The Ultima 1000 is low in heigh and this line has to fit a union, diverter valve and ball valve in a tight space. As you can see it's about an 1.5" too high and no ball valve yet.

Swapping out the unions for Ace Hardware brand (middle) is 1/4" shorter in height than Home Depot brand (right) plus the union style matches the union ball valves (left) better. Still 1.25" to go though.

I bought a thread x thread union and a schedule 80 threaded nipple for the bottom and kept the slip side of the union for the top, eliminating two fittings or any combo thereof. Removing the thread x slip adapter on either side of the union buys us the 1.25" in height needed and looks like a normal union.

Before & after