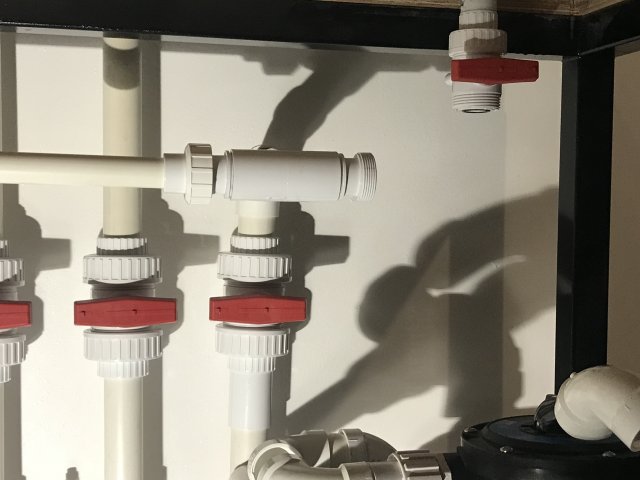

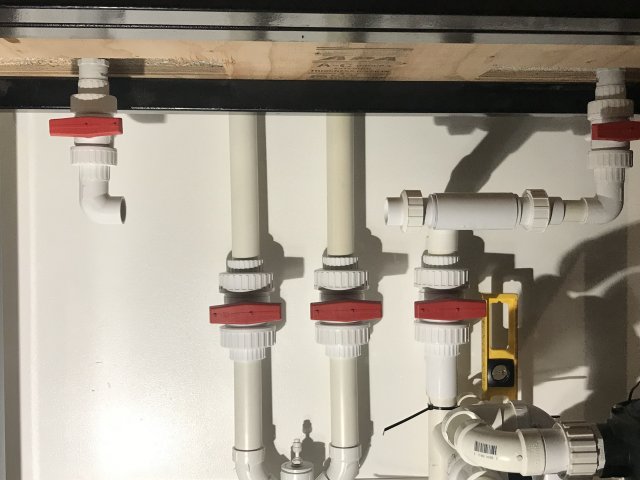

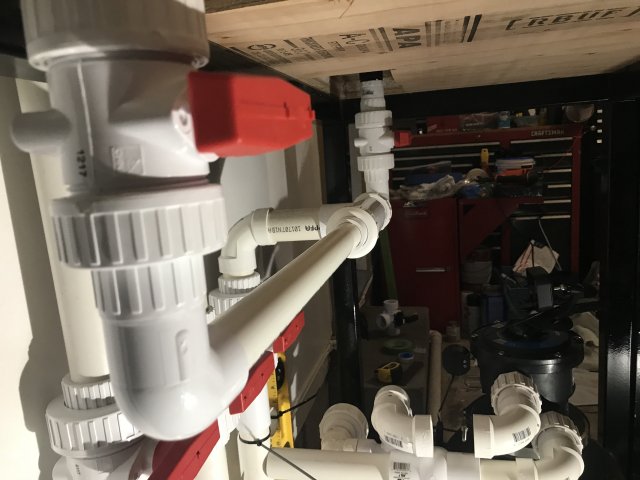

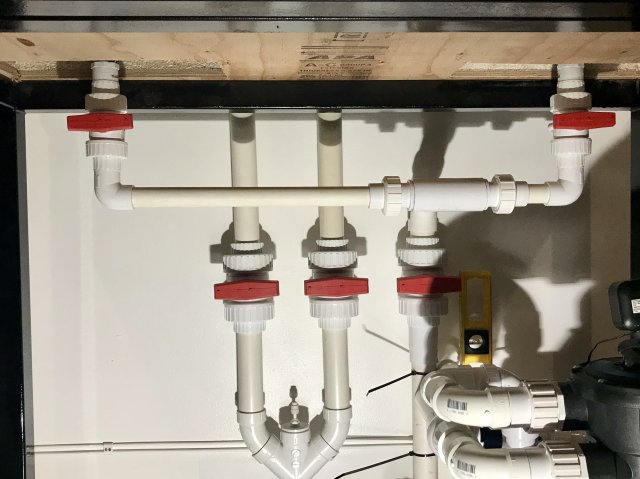

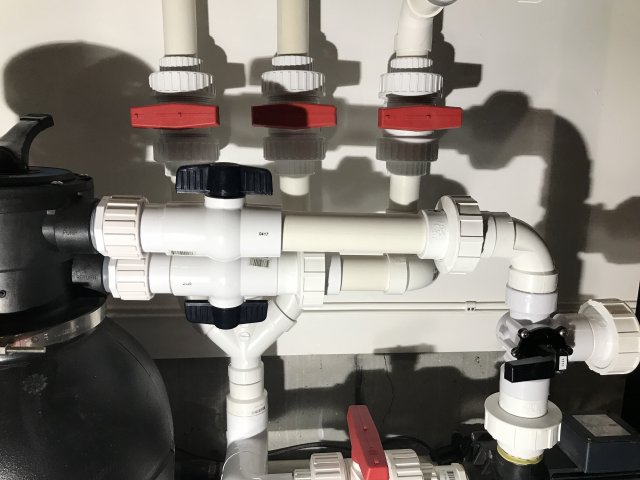

JK47 bit confused. How many returns and intakes you going to have? I see the braided line but don't understand what its purpose as a return is for? Your overflows each have two intakes and then you will use powerheads to "return" water out of them. I think I see 4 returns coming through the top of the tank, so what are the returns in the towers?

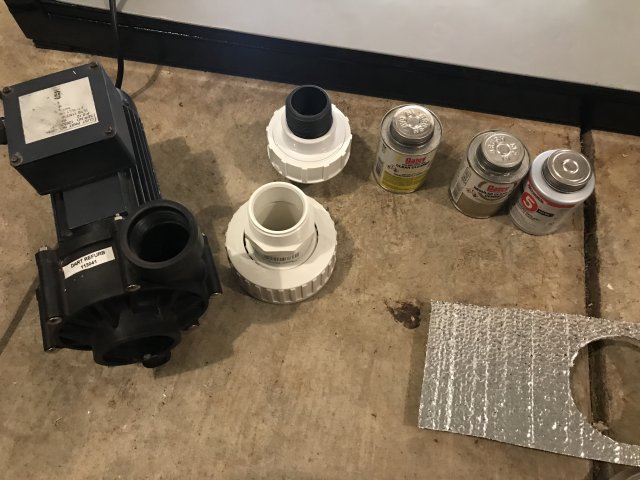

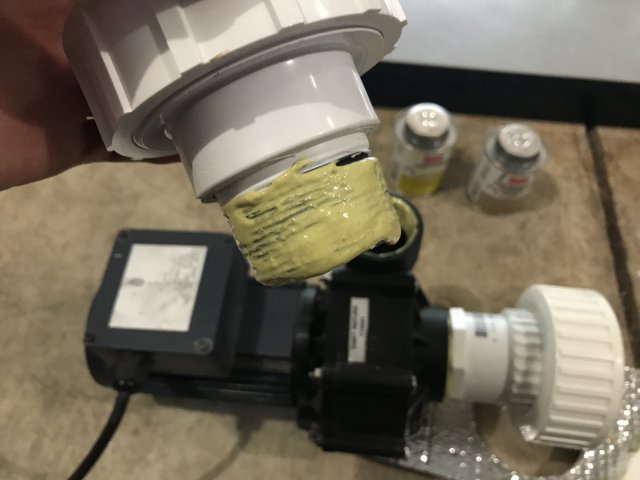

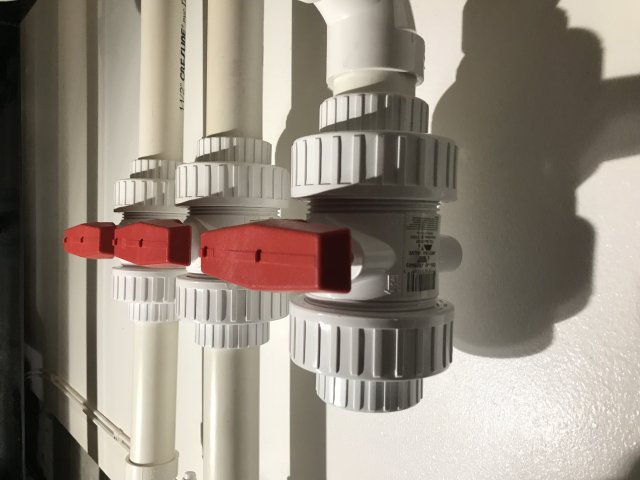

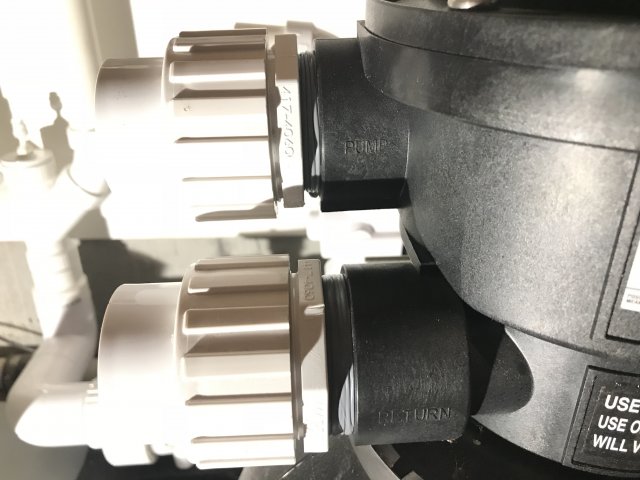

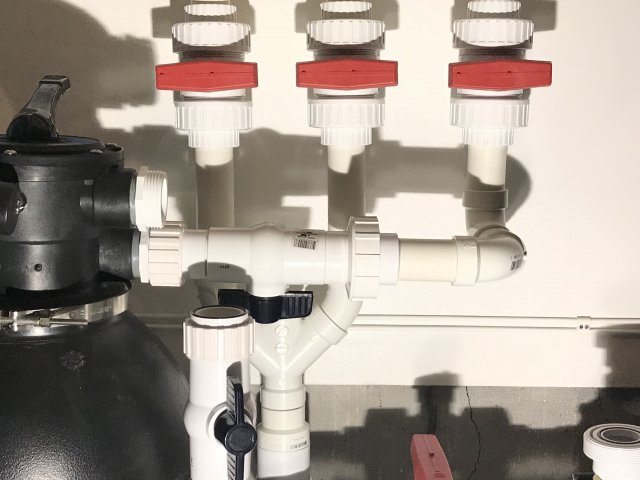

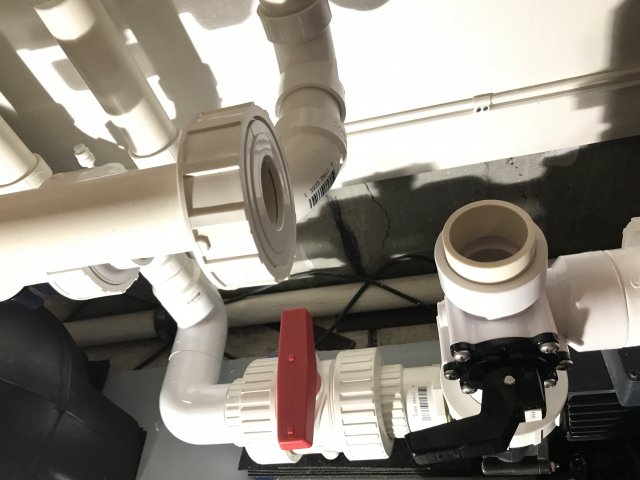

There are two 1.5" intakes and two 3/4" returns. The returns on the top most likely be used on one of the other 6x3's since they are obsolete on this tank now.

I changed my mind multiple times and in the end decided returns going up and over were adding a couple feet of head height and not bringing any value vs plumbing them up through the tower.