Acrylic seam repair/ assessment

- Thread starter Johnpeck1

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nothin i havent seen or fixed before… its def. salvageable. Pretty cool shape id def. put in the time and maybe $100 to give it some new life. Ive owned 30-40 yr old acrylic tanks for the better part of my fish keepin days. These things just happen to material over time. Cracks in the top braces are very common aswell. The top sheet of an acrylic tank actually takes the most stress/pressure. Any cracks that are “running” simply drill a 1/8”-1/4” hole through to stop them. As for the seams… theres no way around draining the tank for a repair. Id throw in some heavy fillets of weld on 40 around 1” or enough to encapsulate any of the old rod/reinforcement… Do both back upright seams and let er rip again for another 20+ yrs. youd have to drain, clean and pull the tank out, thats just part of the process. The fish can be setup and kept in an inflatable kiddie pool or rubbermaid stock tank while u do the repair. Brand new tanks can fail just the same acrylic or glass, just part of the game we play. Weigh ur options and go for it… or start lookin for a new tank. Theres no way to repair it while its up and running or on the stand… 1st step is find something to transfer the fish into. Doesnt have to be pretty or permenant. U need maybe a month of time to strip and repair the tank. Acrylic rod with weld on 40 will work to fix it or just a heavy fillet of 40 as ive mentioned before. Ive poured “fillets” up to 3” wide for repairs like this that hold and reinforce the tank just fine. They can be a bit unsightly but being on the back wall i dont see much of a problem even for looks. It is also possible to patch from the outside to cover the entire seam with a strip of acrylic and weld on 40. Ud have to cut a bit of drywall to compensate but thats an option and almost a “last resort” if any inner tank work/repairs dont work. Acrylic is always salvagable. Just depends if u want to put in the time to make it right. Do not be discouraged by naysayers who are not familiar with the materials or the repair process. Theres always a way. Ive repaired many similiar seams… ive even repaired tanks that blew out their bottoms ?. Again just depends if u have the time and will to do it.

Sadly u cant trust all tank mfg… half of them dont know what theyre doing in the 1st place. For one, they will almost always try and just sell u a new tank. Two, they build tanks with thinner material, cheap material or inadequate solvents/glues for more pofit… just the way the world works. Prob y theres reinforcemnt around the inside in the 1st place. Doesnt make it a “wash” tho. Its held all these yrs and that says alot for the durability of acrylic. About every tank ive owed was under built and purchaced in this exact fashion. With some tlc they can be made like new again. Honestly tanks were made better 30+ yrs ago. The knowledge of the material thickness was lacking a bit but they made up for it with internal seam bracing and the use of weld on 40 fillets. Water just cant get through a 1-3” seam very easily even if the pressure of bowing is pushing the material to its limits. Again… the big thing is basically “do you find this project fun” lol… i used to enjoy it. The quick and “easy” solution is throw money at it for new. If u dont have lots of money… u pay for it with time, research and getting ur hands dirty to do it urself. Some times it works… some times u have to try again… its how u deal with the problems when there presented… not the problem ??. Pro tip… its almost fall… “kiddie pools” are on sale everywhere right now lol… #BeenThere…

Sadly u cant trust all tank mfg… half of them dont know what theyre doing in the 1st place. For one, they will almost always try and just sell u a new tank. Two, they build tanks with thinner material, cheap material or inadequate solvents/glues for more pofit… just the way the world works. Prob y theres reinforcemnt around the inside in the 1st place. Doesnt make it a “wash” tho. Its held all these yrs and that says alot for the durability of acrylic. About every tank ive owed was under built and purchaced in this exact fashion. With some tlc they can be made like new again. Honestly tanks were made better 30+ yrs ago. The knowledge of the material thickness was lacking a bit but they made up for it with internal seam bracing and the use of weld on 40 fillets. Water just cant get through a 1-3” seam very easily even if the pressure of bowing is pushing the material to its limits. Again… the big thing is basically “do you find this project fun” lol… i used to enjoy it. The quick and “easy” solution is throw money at it for new. If u dont have lots of money… u pay for it with time, research and getting ur hands dirty to do it urself. Some times it works… some times u have to try again… its how u deal with the problems when there presented… not the problem ??. Pro tip… its almost fall… “kiddie pools” are on sale everywhere right now lol… #BeenThere…

So by "fillet"you mean tip the tank and pour the Weldon 40 right over the existing reinforcement rod? I read that just pouring on Weldon actually could weaken the existing joint...do u buy that? A fish store guy with a connection to an acrylic tank maker in florida wanted to fabricate an L shaped acrylic rod that would fit over the existing square rod and weld that in. Couldnt that be done without taking the tank off the stand? I guess that depends on how thick the weldon 40 is. My idea would be to apply it to the L shaped rod and then press the rod in place. If you think the weldon 40 is too runny for that, is there another product that is thick enough to do this? How long does it take to dry? You mentioned the fish would be relocated for a month.

Sorry for all the questions, but you seam like the guy with the answers. Seriously, Jersey is pretty this time of year...

wednesday13 Thank you for an awesome answer!!! Really well written! Can I fly u up from the south to Jersey to help me do this?!?

So by "fillet"you mean tip the tank and pour the Weldon 40 right over the existing reinforcement rod? I read that just pouring on Weldon actually could weaken the existing joint...do u buy that? A fish store guy with a connection to an acrylic tank maker in florida wanted to fabricate an L shaped acrylic rod that would fit over the existing square rod and weld that in. Couldnt that be done without taking the tank off the stand? I guess that depends on how thick the weldon 40 is. My idea would be to apply it to the L shaped rod and then press the rod in place. If you think the weldon 40 is too runny for that, is there another product that is thick enough to do this? How long does it take to dry? You mentioned the fish would be relocated for a month.

Sorry for all the questions, but you seam like the guy with the answers. Seriously, Jersey is pretty this time of year...

I dont buy it no lol… ive tip n poured #40 fillets in multiple tanks 200-450 gal and have done countless repairs with it on 100-500gal tanks. Ive even used jigs to repair golf ball size holes in tank corners that come out looking new from tanks being dropped during transport… helped countless people here over the yrs also with success on a multitude of problems. Tanks can be built with #40 also…Will the L shaped acrylic rod work, yes… will the glue run down a bit, yeah… but it might just puddle a bit at the bottom and be covered by substrate. U can honestly probably move the tank off the stand one end at a time by urself, work on it then get it back up. #40 is pretty “hazerdous” also. If u have a family keep em out of the house for a day while ur working on it. Wear a good respirator and stick a fan out a window to move air. The glue will set up in 30-45 minutes and be fully cured in a week. I usually wait two weeks just to be safe. Overkill sure… ive done “emergency” repairs for shops on site and filled the tanks back up same day but if u have the time, b patient and wait. Nothing worse than doing it over. I see u caught the “joke” in my profile/sig…im from “The Deep South” i.e. “hell” i.e. Ohio ?????? haha… Little Nicky quote…. I do have some friends in jersey… Im a lure maker these days tho for Pike and Musky… and its fall… so business is full swing right now as well as Pike/Musky season. If im not workin my “day job” for health care im workin in my bait shop or hiding in the woods chasin monsters ??… ull b ok man ? its always the hardest before u start. Ite’ll feel good when its all over and u know u can fix anything thats thrown at ya down the road. Ill check back here if u have any questions np…

Pouring weld on “solvent” #3 or #4 while a tank is full will weaken/pop the seam yes… maybe thats what u read. As long as everything is dry ur good to go ?. Theres a cple differnet glues that will work from weld-on… #40 is by far the best for old/used material tho. A pint kit should cost ya around $35 and be more than plenty for the job. That with the addition of the the L shaped rod should seal the deal pretty easy if u cant get the tank out. Make sure to scuff up the old rod, new rod and seam area with heavy grit sandpaper. Will help ur “patch” get a good bite into the old material and any sanding marks the glue touches will also turn clear once glued. The 40 is a bit runny but its the thickest they offer. U can do a vertical patch. Use plenty glue… masking tape it in place after u put it on and wait… the glue actually works better with a gap so dont squeeze it all back out either. Lightly tape it in place once the air bubbles are pushed out and it should last another life time.

You can name your price if you want to take a 2 day vacation. Striped bass are coming in here!

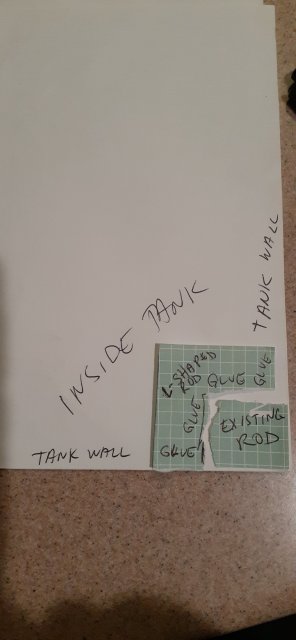

I attached a drawing looking in from the top. So i would have to get glue on 4 sides of the L. Seems like thats impossible with a runny product. Is weldon 16 thicker than 40? I was hoping for more of a gel like substance. Does all the glue go on the new rod or do you put some on existing rod/ tank corner walls? Sounds like a huge mess. Can I make tape lines like u would do with caulk?

Can you walk me through the fillet way of doing it? How heavy do u think a 72x23x28 tank weighs. Im guessin you have to get it up on its side corner to just pour the weldon in and keep it level.

Damn man, this is all I think about. Im losing it. Meanwhile the guy who said he can grt me the L-rods hasnt called me back.

I cant thank you enough for all your help!!!

Last edited:

@Wednesday1

Really man, thank you. I learned more than i could imagine!Pouring weld on “solvent” #3 or #4 while a tank is full will weaken/pop the seam yes… maybe thats what u read. As long as everything is dry ur good to go ?. Theres a cple differnet glues that will work from weld-on… #40 is by far the best for old/used material tho. A pint kit should cost ya around $35 and be more than plenty for the job. That with the addition of the the L shaped rod should seal the deal pretty easy if u cant get the tank out. Make sure to scuff up the old rod, new rod and seam area with heavy grit sandpaper. Will help ur “patch” get a good bite into the old material and any sanding marks the glue touches will also turn clear once glued. The 40 is a bit runny but its the thickest they offer. U can do a vertical patch. Use plenty glue… masking tape it in place after u put it on and wait… the glue actually works better with a gap so dont squeeze it all back out either. Lightly tape it in place once the air bubbles are pushed out and it should last another life time.

wednesday13 Ohio! Birthplace of the great David Allan Coe!

You can name your price if you want to take a 2 day vacation. Striped bass are coming in here!

I attached a drawing looking in from the top. So i would have to get glue on 4 sides of the L. Seems like thats impossible with a runny product. Is weldon 16 thicker than 40? I was hoping for more of a gel like substance. Does all the glue go on the new rod or do you put some on existing rod/ tank corner walls? Sounds like a huge mess. Can I make tape lines like u would do with caulk?

Can you walk me through the fillet way of doing it? How heavy do u think a 72x23x28 tank weighs. Im guessin you have to get it up on its side corner to just pour the weldon in and keep it level.

Damn man, this is all I think about. Im losing it. Meanwhile the guy who said he can grt me the L-rods hasnt called me back.

I cant thank you enough for all your help!!!

View attachment 1473923

Haha, bribing me with some striper fishing is pretty tempting ?… looks like ur on track with ur drawing/mock up. IMO #16 is straight junk. More so for crafts and repairs that will come back to haunt u later. #16 is actually just #3 or #4 solvent with acrylic melted into it for more consistency. It is runnier than #40 and weaker than just solvent #3/4…. U can do the repair/patch with solvent alone but the odds of it coming out right are not good lol… solvent is tricky to do right.

I would use the 40… basically mix it up, pour out or brush onto both rod and tank, all surfaces and slap it on lol… u have around 15 minutes to do this before it starts setting up/getting hot. Can wipe off any squeeze out/excess with paper towels. Tape will work but theres really no way around the mess, try and be as clean as u can. Any glued spilled onto the acrylic will leave marks. U can sand/buff it clear again but thats a whole nother process to learn.

As for moving the tank/tipping it for fillets id say its a 2 person move… or 1 person struggle as u move one end off the stand at a time. Acrylic is light… if that seams goin its underbuilt but easier to move lol… i did a 450 by myself before. 1 step/move at a time. Didnt go far from the stand but it was doable. There easy to tip up to pour, stand removal is the biggie. More so getting it back up onto it but if u can get a hand for that part, no sweat. Tip n pour is an easy process. Just mix ur glue and pour right across the whole seam. Its pretty self leveling, u dont have to touch it at all. Ive used a spoon to spread out any high areas but its not needed with 1 good pass/pour of glue right out of the mixing cup.