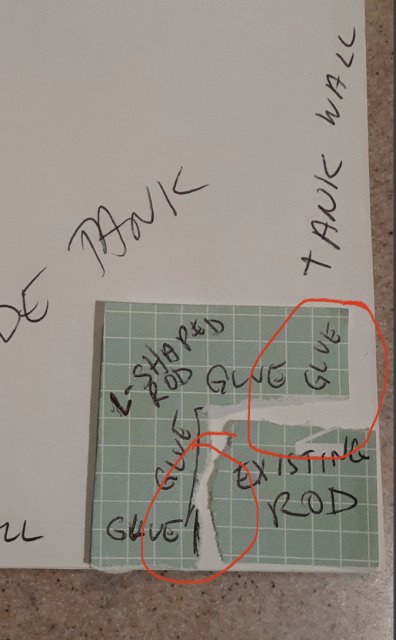

Thanks bro!!! Sooo, i measured the existing rod with callipers. I got a few different measurements but it seems like 9.2 mm square from tank wall to edge of existing rod. What size square rod would you use to fit over it? 3/4 inch? And would you cut 9.3 mm right angle out to make room for glue and still hit tank wall?

And now that the guy who said he could get me the new rods has stopped answering me, who sells and "routs" square rods. Any ideas?