Ok, so I just got my 220 up and running with my 55 gallon sump underneath and, for my first sump setup, it is just too noisy. I can hear it from most of the house (which isn't a very big house, but still...). So, can you all please take a look at the pictures of my setup and let me know if you have any suggestions to quiet the setup down?

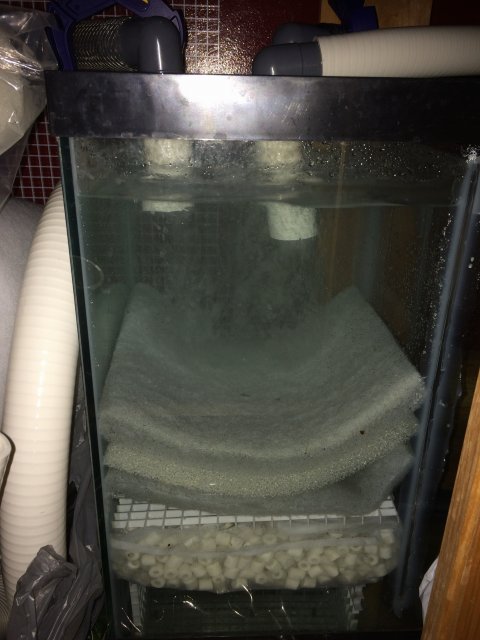

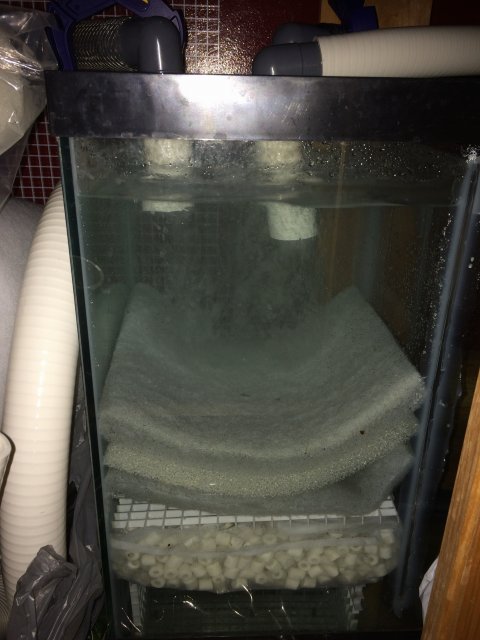

Here is a front view of the tank, and you can kind of make out the 55 gallon sump underneath.

Here is the first sump chamber. A bit of a bubbling sound comes from here but it's not that loud and isn't much of the overall tank sound.

Here is chamber number two (the middle chamber) in the sump. It is just a refugium area that houses the heaters. No noise comes from here.

Here is the last chamber where the pumps are at. A slight hum comes from the pumps, but is also not that bad and is not much of the overall tank noise.

Here is the baffle that the water flows over to get to the pump chamber. With the sponge it is pretty much silent.

Here is a picture of the plumbing behind the tank (sorry, not the greatest picture). Is appears that about half of the noise is water noise that comes from this area.

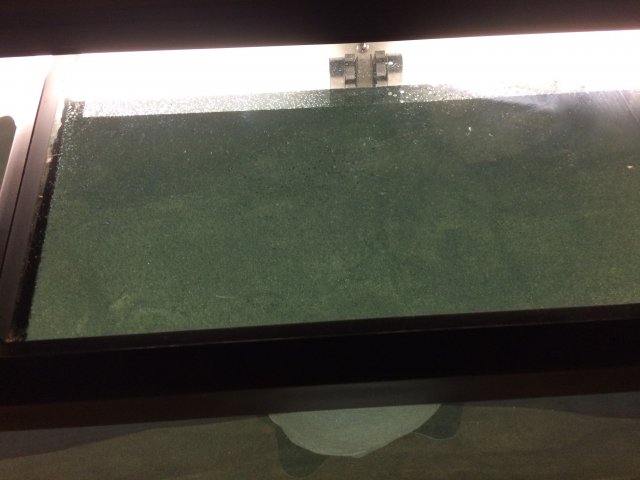

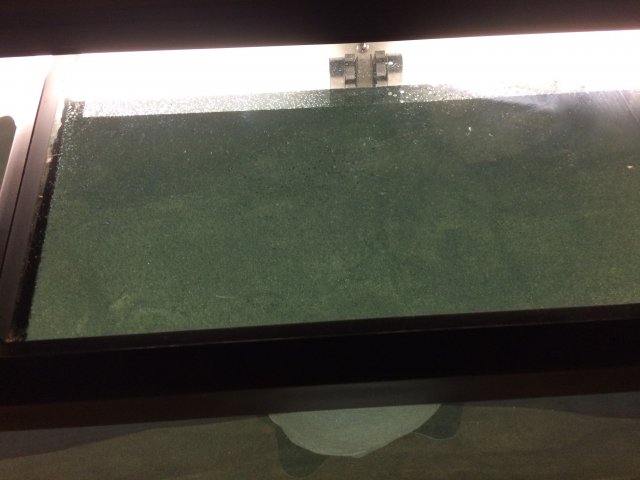

Here is a picture from the top of the tank. There are three H2Overflows and two 3/4" returns. It appears that about half of the noise is coming from the water draining into the overflows.

No noise from the power strip and heater controller, but I wanted to give a comprehensive set of pictures.

Again, not much noise from the pumps. They are Rio 20HF's and at the current head height my total flow rate should be around 1,500gph.

Front view of the tank.

I have the water level perfect so that the glass brace acts as a top view panel on the tank.

Close up view of one of the H2Overflows.

Close up view of one of the returns.

View under the tank of the 1.5" drain lines from the overflows.

Ok, sorry for the lengthy post but I want to be thorough because if I can't get this quite a bit quieter then the tank is going to have to go, and I really don't want that.

Stuff I've already done to make some improvements:

First, I removed the "siphon Stopper" part of each return and replaced them with an elbow that has holes drilled in each side to break the siphon when the pumps are off. This is why you see the white elbow on each of the returns (I have black ones coming but wanted to get things running so I grabbed white from the hardware store). This got rid of the water jet noise that the siphon stopper created by having the break holes above the waterline. However, the water should still drain to the exact same height.

Next, I placed the medium sound rings in each of the H2Overflows. This helped to reduce the water draining noise, but it's still pretty loud.

Things that I'm thinking about doing to make this particular setup quieter:

First, I am planning to cover the top of the tank with .220" acrylic pieces. Do you guys think that this will work to block a lot of the sound that is coming from the top of the tank?

Next, I am thinking about installing some decent pipe insulation on the 1.5" overflow lines all the way from the bulkhead to the sump. Do you all think that this will have much effect on the noise coming from the lines behind the tank?

Lastly, a am considering adding covers to the top of the sump and drilling holes for the return lines and the overflow lines to fit snugly in. This is a bit of a long shot in my opinion, but do you think that it will have much effect?

Other things I'm considering that are a bit more extreme:

Mainly, I am considering taking the H2Overflows off and putting different height pieces of PVC in place. I would then install a gate/ball valve on my lowest overflow and set it up to be full siphon. The other two would then be emergency overflows in case something ever blocks the primary siphon drain.

Last resort, put the new to me tank that I have dreamed of having and put so much time and effort into setting up, up for sale and let the buyer break it down and haul it away instead of me doing anything else with it. I hate to even think of this as an option, but at the noise level it's currently at, I won't be able to keep it.

Once again, thank you all for your help.

Here is a front view of the tank, and you can kind of make out the 55 gallon sump underneath.

Here is the first sump chamber. A bit of a bubbling sound comes from here but it's not that loud and isn't much of the overall tank sound.

Here is chamber number two (the middle chamber) in the sump. It is just a refugium area that houses the heaters. No noise comes from here.

Here is the last chamber where the pumps are at. A slight hum comes from the pumps, but is also not that bad and is not much of the overall tank noise.

Here is the baffle that the water flows over to get to the pump chamber. With the sponge it is pretty much silent.

Here is a picture of the plumbing behind the tank (sorry, not the greatest picture). Is appears that about half of the noise is water noise that comes from this area.

Here is a picture from the top of the tank. There are three H2Overflows and two 3/4" returns. It appears that about half of the noise is coming from the water draining into the overflows.

No noise from the power strip and heater controller, but I wanted to give a comprehensive set of pictures.

Again, not much noise from the pumps. They are Rio 20HF's and at the current head height my total flow rate should be around 1,500gph.

Front view of the tank.

I have the water level perfect so that the glass brace acts as a top view panel on the tank.

Close up view of one of the H2Overflows.

Close up view of one of the returns.

View under the tank of the 1.5" drain lines from the overflows.

Ok, sorry for the lengthy post but I want to be thorough because if I can't get this quite a bit quieter then the tank is going to have to go, and I really don't want that.

Stuff I've already done to make some improvements:

First, I removed the "siphon Stopper" part of each return and replaced them with an elbow that has holes drilled in each side to break the siphon when the pumps are off. This is why you see the white elbow on each of the returns (I have black ones coming but wanted to get things running so I grabbed white from the hardware store). This got rid of the water jet noise that the siphon stopper created by having the break holes above the waterline. However, the water should still drain to the exact same height.

Next, I placed the medium sound rings in each of the H2Overflows. This helped to reduce the water draining noise, but it's still pretty loud.

Things that I'm thinking about doing to make this particular setup quieter:

First, I am planning to cover the top of the tank with .220" acrylic pieces. Do you guys think that this will work to block a lot of the sound that is coming from the top of the tank?

Next, I am thinking about installing some decent pipe insulation on the 1.5" overflow lines all the way from the bulkhead to the sump. Do you all think that this will have much effect on the noise coming from the lines behind the tank?

Lastly, a am considering adding covers to the top of the sump and drilling holes for the return lines and the overflow lines to fit snugly in. This is a bit of a long shot in my opinion, but do you think that it will have much effect?

Other things I'm considering that are a bit more extreme:

Mainly, I am considering taking the H2Overflows off and putting different height pieces of PVC in place. I would then install a gate/ball valve on my lowest overflow and set it up to be full siphon. The other two would then be emergency overflows in case something ever blocks the primary siphon drain.

Last resort, put the new to me tank that I have dreamed of having and put so much time and effort into setting up, up for sale and let the buyer break it down and haul it away instead of me doing anything else with it. I hate to even think of this as an option, but at the noise level it's currently at, I won't be able to keep it.

Once again, thank you all for your help.