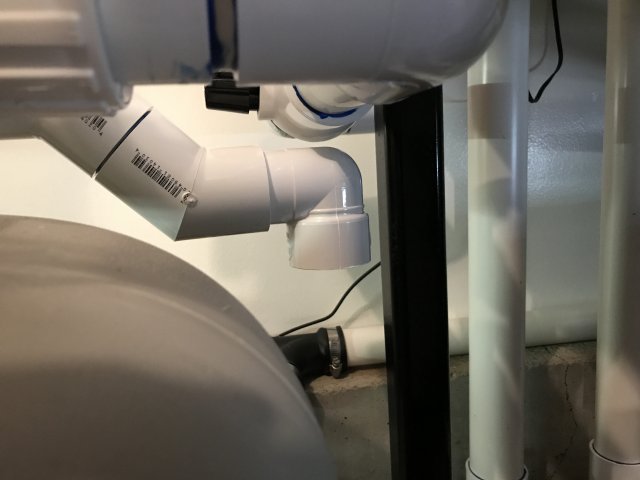

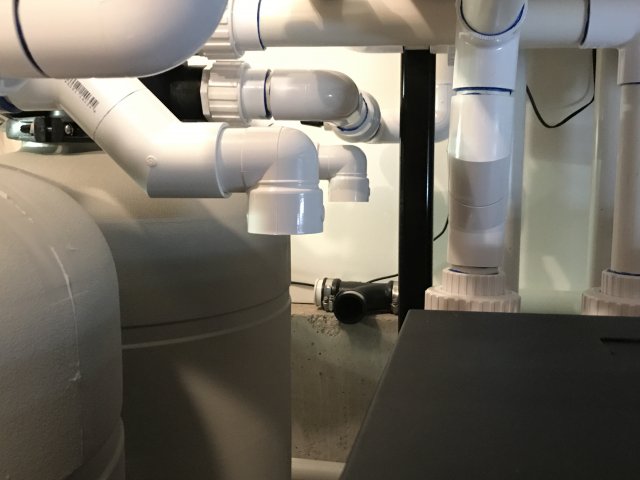

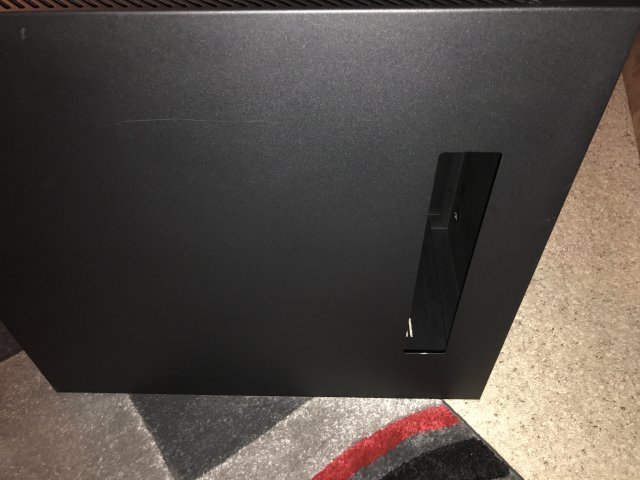

The knock outs for the cabinet are on the bottom. I used a set of pvc couplings as legs to elevate the cabinet so the wires can go underneath.

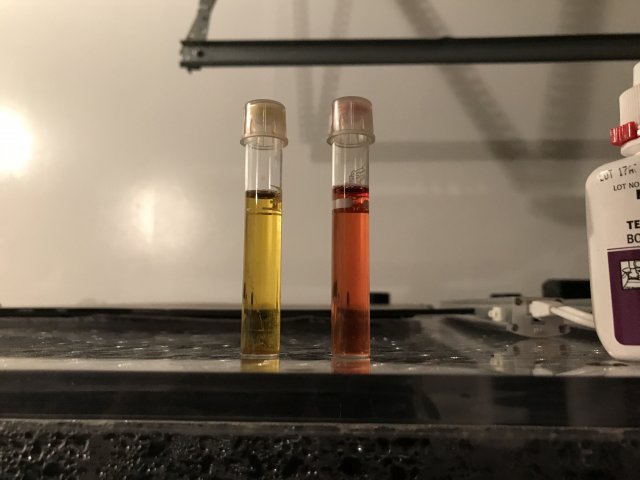

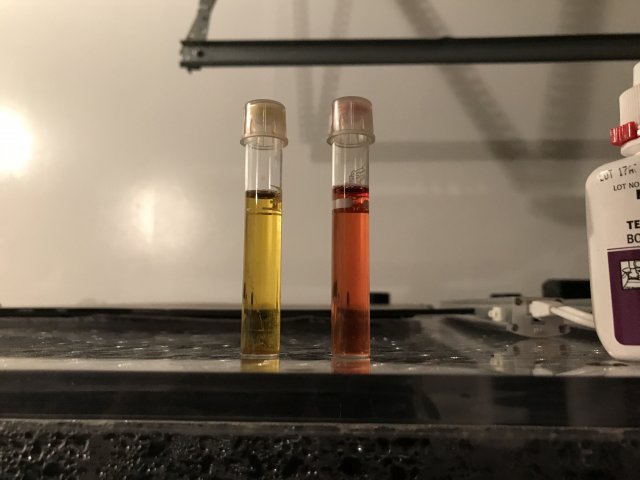

Ammonia is slowly decreasing and the last pic is nitrate creep over 48 hours. Not much but the cycle is getting close. Looks like stock will be going in within the next few days

Ammonia is slowly decreasing and the last pic is nitrate creep over 48 hours. Not much but the cycle is getting close. Looks like stock will be going in within the next few days