This is looking very nice!

Will you use bottom drains to sump?

Will the sump have individual chambers for settlement and purge taps to clean ?

I'm interested in your seive. Will it be wedge wire screen ?

How will you waterproof the wood/concrete. No glass viewing panel ? It could easily be done for 650mm water depth.

Wow, that's a lot of questions in a short post..lol..

No bottom drains.. the concrete layer was only to get over the ridges. It's less than 20mm in most places.

The sump is not your usual fish-pond sump. it's basically a vessel to keep the pond level steady.

It's an aquaponics system, so lots of water will be going into and out of the grow-beds, flow into the pond and then get into the sump.

To make sure there's no debris and fish waste solids going into the grow beds, the screen is there to filter out as much as possible.

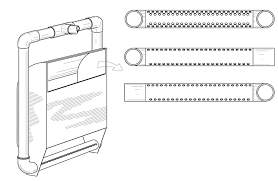

It's not going to be a wedge wire screen, too expensive. instead I took a 300 micron stainless mesh.

Will be fitted into a frame and the rubbish will flow into a filter-sock that needs to be cleaned out.

Instead of using a bottom drain, I'll be trying to build a rectangular air-lift pump which, if my thoughts and plans are correct, will lift a sizeable amount of water and gunk from the bottom of the pond up into the sump (and on top of the wire-mesh screen).

Windows are nice, but they would not fit the overall looks of the pond.

Waterproofing will be fairly easy..lol.. Liner.. Already ordered and delivered.

The sump will have no chambers whatsoever except for the screen.

The bio-filtration will take place in the grow-beds which are filled with expanded clay balls.

Total growbed volume estimated at 3x1x0.2m, which would equal a 0.6 cbm (or 600 litre) of clay-balls.

Should be plenty enough for some very happy Koi and vegetables growing like they're on steroids.

Volume of the water for the Koi (swimming area) estimated at 2000 litre, but need to do some better measuring some time soon.

Still, I guess that 600 litre of very porous clay balls for bio-filtration on 2000 litre water is not going to give me much problems.

And of course, solids being filtered out by the screen, so it's only amonia to be converted into plant food.

Hope that explains it a bit more!

Cheers,

Luc